- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

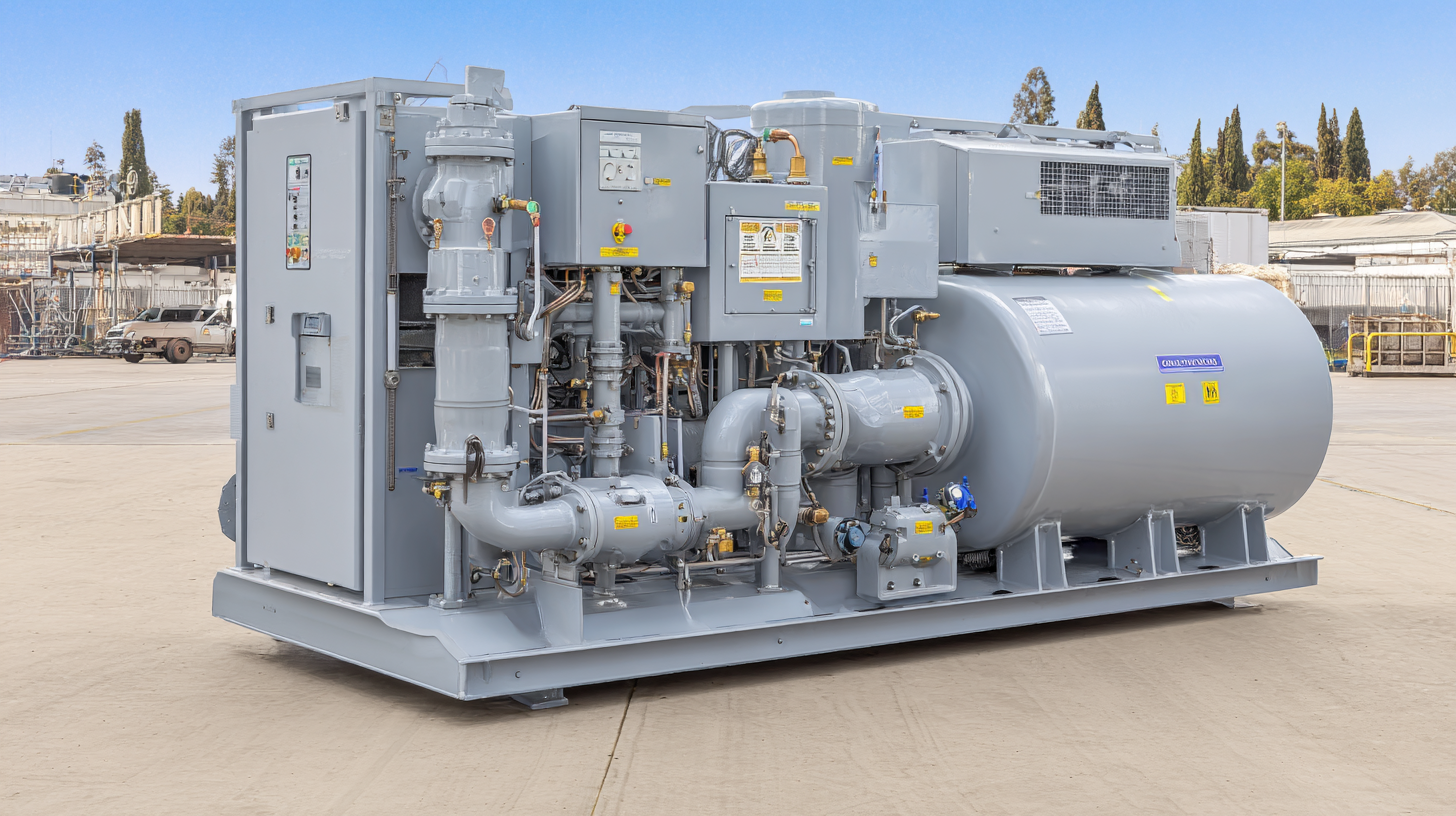

In the fast-evolving landscape of industrial operations, investing in advanced technology is crucial for maintaining competitive efficiency. The 2023 Compressor Dryer stands out as a transformative solution, offering manufacturers a pathway to enhanced productivity and reduced operational costs. According to a recent report by MarketsandMarkets, the global market for industrial dryers is expected to reach $5.2 billion by 2026, with a significant shift towards energy-efficient systems that minimize waste and operational downtime.

This trend underscores the importance of adopting state-of-the-art equipment like the Compressor Dryer, which not only streamlines processes but also contributes to substantial energy savings. With companies increasingly focused on sustainability and cost-effectiveness, the 2023 Compressor Dryer exemplifies the future of industrial efficiency, making it an essential investment for businesses aiming to thrive in a competitive environment.

The 2023 Compressor Dryer represents a significant advancement in energy efficiency, delivering substantial benefits for industrial operations. By optimizing energy consumption, these dryers can reduce operational costs dramatically, allowing businesses to allocate resources more effectively. Enhanced efficiency not only lowers electricity bills but also minimizes the environmental impact, contributing to sustainability goals that are increasingly crucial in today’s industrial landscape.

Tips for maximizing the benefits of your 2023 Compressor Dryer include regular maintenance and monitoring of energy usage. Implementing scheduled checks can prevent inefficiencies and prolong the lifespan of your equipment. Additionally, consider integrating advanced control systems that can provide real-time data on performance, helping to identify areas for further improvement.

Moreover, investing in training for staff on the operation and maintenance of these dryers can lead to better performance and lower downtime. Educated personnel are more likely to recognize and address issues before they escalate, further preserving the operational cost savings afforded by this state-of-the-art technology. Emphasizing energy efficiency in training programs ensures that every team member is aligned with the company’s commitment to operational excellence.

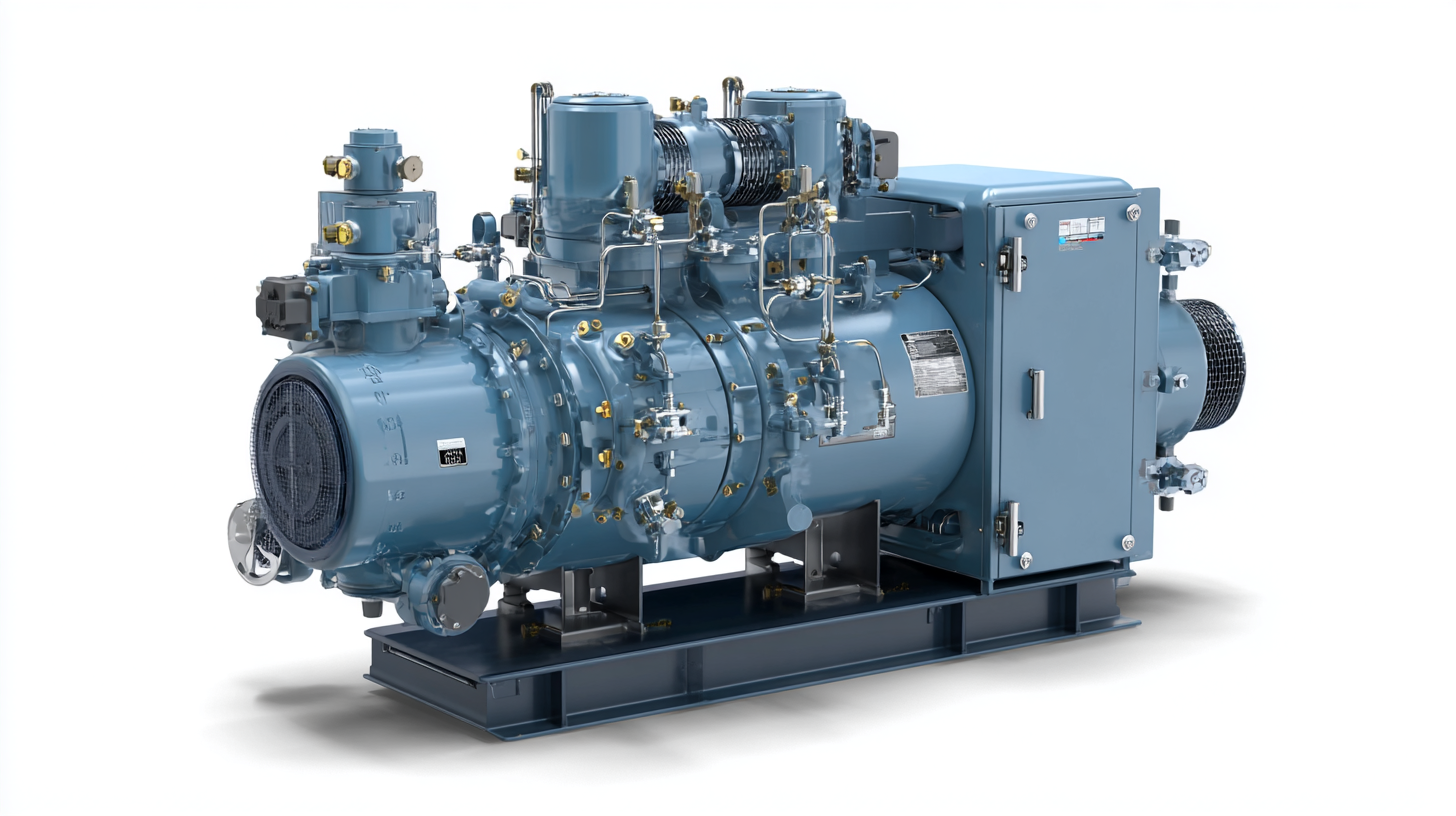

The 2023 Compressor Dryer stands out as an exceptional investment for industrial efficiency, particularly due to its innovative technology features that significantly enhance productivity and reliability. One remarkable advancement is its energy efficiency, which is highlighted in the 2022 Annual Report by the International Energy Agency (IEA), stating that industrial energy consumption could be reduced by up to 30% with the adoption of modern compressor technologies. This translates not only to cost savings but also reduced environmental impact, aligning with sustainability goals increasingly prioritized by industries worldwide.

Moreover, the latest models incorporate smart monitoring systems that provide real-time data analysis, enabling operators to optimize performance proactively. A recent study by the Manufacturing Institute found that organizations utilizing such technologies reported improvements in uptime by as much as 25%. This capability allows for better resource management and informed decision-making, driving operational excellence in a competitive market.

Tips: To maximize the benefits of your compressor dryer, consider regular maintenance to ensure optimal performance. Additionally, leveraging the data analytics features can equip your team with valuable insights for making process adjustments. Lastly, evaluate your energy consumption patterns and make informed upgrades to harness the full potential of the innovative technology integrated into modern dryers.

The 2023 compressor dryers are revolutionizing industrial efficiency compared to traditional models. An in-depth comparative analysis reveals that these newer systems not only enhance operational efficacy but also optimize energy consumption, leading to significant cost savings in various industrial applications. Industries such as petrochemical, mechanical manufacturing, and mining are increasingly adopting these advanced dryers, driven by their ability to provide better air quality and increased reliability in lengthy operational runs.

Market research indicates that the global air compressor market is on an upward trajectory, with significant growth anticipated across all sectors. In particular, the rise in demand for rotary screw compressors and reciprocating air compressors reflects the continued preference for advanced technologies that deliver superior performance. Moreover, regional analyses highlight robust growth in regions actively investing in infrastructure and industrial expansion, further solidifying the position of 2023 compressor dryers as a crucial investment for companies aiming to enhance their operational capabilities.

Investing in a 2023 compressor dryer can significantly enhance the efficiency of industrial operations. One of the key advantages is its energy efficiency, which contributes to long-term cost savings. By upgrading, businesses can expect a reduction in energy consumption, resulting in lower utility bills and a substantial return on investment (ROI) over time.

**Tip:** Regular maintenance of the compressor dryer is essential to maintain its efficiency. Scheduled inspections can prevent costly breakdowns and ensure that the system operates at peak performance, further enhancing your ROI.

In addition to energy savings, the latest compressor dryers are equipped with advanced technology for improved performance. They minimize downtime with faster processing capabilities and reduced operational costs. These dryers are also designed to have a longer lifespan, allowing companies to rely on them for years without the need for frequent replacements, which translates into additional financial benefits.

**Tip:** Consider investing in training for your maintenance team specifically tailored to the new equipment. Proper training can optimize equipment operation and troubleshooting, thus prolonging the dryer’s life and maximizing your investment.

| Reason | Benefit | Estimated Cost Savings Over 5 Years ($) | Potential ROI (%) |

|---|---|---|---|

| Energy Efficiency | Reduces energy consumption, lowering utility bills | $25,000 | 150% |

| Increased Reliability | Reduces downtime due to failures, ensuring continuous operations | $15,000 | 100% |

| Lower Maintenance Costs | Fewer breakdowns lead to decreased maintenance expenses | $10,000 | 80% |

| Enhanced Performance | Improves overall processing speeds and quality | $20,000 | 120% |

| Sustainability Goals | Supports corporate sustainability initiatives | $5,000 | 60% |

The 2023 Compressor Dryer represents a significant advancement in industrial technology, particularly in its alignment with sustainability goals. As industries increasingly focus on reducing their environmental impact, compressor dryers have emerged as essential tools for enhancing operational efficiency while minimizing energy consumption. The global compressed air dryer market is projected to grow from USD 4.7 billion by 2025 to USD 7.7 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.1%. This growth underscores the demand for technologies that not only optimize performance but also contribute to a greener industrial landscape.

Moreover, leading manufacturers are prioritizing innovation in sustainable technologies, which include advanced compressor dryers designed to reduce energy waste and lower greenhouse gas emissions. With the global screw compressor market expected to expand from USD 16.36 billion in 2025 to USD 22.82 billion by 2035, the integration of environmentally friendly designs in manufacturing processes is becoming a defining trend. By investing in the latest compressor dryer technologies, industries can align their operations with global sustainability goals, effectively balancing profitability and ecological responsibility.