- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the realm of precision machining, the choice of Clamping Collets plays a vital role. These components are crucial for securing workpieces during milling, turning, and grinding operations. A good collet ensures stability and accuracy, leading to better outcomes in manufacturing.

As we approach the year 2026, advancements in material technology and design promise enhancements in Clamping Collets. The market is filled with options, yet not all provide optimal performance. Some may be too loose while others can exert excess pressure on delicate materials. These factors greatly affect machining precision.

It’s essential to review the best Clamping Collets available. Each model varies in grip strength, adaptability, and durability. Missteps in selection can lead to wasted materials and increased costs. Understanding these components is key to refining processes and achieving excellence in machining tasks.

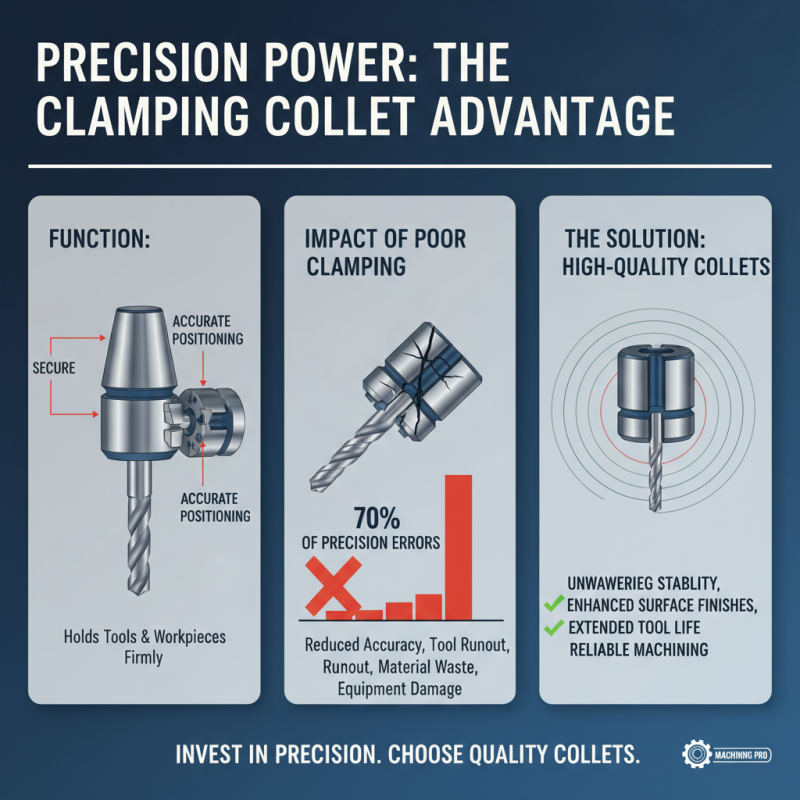

Clamping collets play a crucial role in precision machining. Their main function is to hold tools and workpieces securely. This ensures accuracy in machining processes. According to a recent industry report, up to 70% of precision errors are attributed to poor clamping solutions. This highlights the need for high-quality collets.

Different types of clamping collets cater to various machining needs. The most popular types include expanding collets and drawbar collets. Expanding collets provide a firm grip on differing diameters. However, achieving the perfect expansion can be challenging. On the other hand, drawbar collets are reliable but can sometimes lead to tool slippage if not maintained properly. Regular maintenance is essential to avoid such issues.

Industry experts recommend using collets made from high-quality materials. Superior materials contribute to better durability. A report from the Precision Engineering Association states that around 15% of machining failures relate to subpar collet materials. Choosing the right collet isn't always straightforward. Many users face difficulties in selecting the appropriate type for their specific applications. Understanding the nuances of each collet type can significantly impact machining precision.

When selecting clamping collets, precision is crucial. The right collet ensures the workpiece is securely held during machining. Look at the material of the collet. Steel often provides durability, while aluminum can be lighter and easier to handle. Each material has its pros and cons.

Next, consider the design. Different shapes can influence gripping performance. Some collets are designed for specific tasks. Machining a tight tolerance requires specialized collets. It's essential to evaluate how frequently you change tasks. Frequent changes might need a more versatile collet style.

Also, think about the size compatibility. Ensure the collet fits your tooling needs. Some users overlook this and end up wasting time. Having the wrong size can lead to poor machining quality. Lastly, user feedback can guide your choice. Real experiences often highlight what’s missing in product descriptions. This can help in making a well-informed decision.

| Collet Type | Material | Accuracy (μm) | Clamping Range (mm) | Operating Temperature (°C) |

|---|---|---|---|---|

| ER Collet | High Carbon Steel | 10 | 1 - 26 | -20 to 120 |

| Collet Chuck | Aluminum Alloy | 5 | 3 - 16 | -10 to 100 |

| Capto Collet | Tool Steel | 8 | 1 - 20 | -20 to 150 |

| TG Collet | Stainless Steel | 7 | 2 - 25 | -30 to 120 |

| Hydraulic Collet | Carbon Steel | 6 | 3 - 28 | -20 to 120 |

In 2026, the market for clamping collets in precision machining is thriving. According to industry reports, the demand for high-precision tools has increased by 15% annually. This surge emphasizes the necessity for quality in clamping solutions. Many manufacturers are focusing on improving their designs to enhance grip and stability.

Key aspects revolve around material choice and manufacturing techniques. Collets made from high-speed steel or carbide exhibit superior toughness. Data indicates that tools with improved wear resistance can reduce operational downtime by 20%. However, not all brands meet these rising standards. Inconsistent quality can lead to costly errors and lost productivity.

Also, emerging technologies like additive manufacturing are influencing design trends. Innovative collet configurations promise better performance but require thorough testing. The need for ongoing evaluation is paramount. Shops must remain vigilant about their tool choices to avoid inefficiencies. The landscape remains competitive, but with vigilance, success is attainable.

Precision clamping collets play a crucial role in various industrial applications. These devices are essential in machining, especially in environments requiring high accuracy. In automotive manufacturing, for example, collets securely hold tools, ensuring precise cuts and shapes. This reliability improves the quality of finished products.

In the aerospace sector, clamping collets contribute significantly to the assembly of engines and parts. Here, the tolerances are very tight. A minor error can lead to catastrophic failures. Collets help minimize such risks by providing stable, secure clamping during machining processes. However, there is room for improvement in design. Some collets may not provide uniform clamping pressure, leading to inaccuracies.

In medical device production, precision is key. Collets must handle delicate instruments without damaging them. This requires intricate design and manufacturing processes. The challenge lies in balancing strength and finesse. Continuous innovation is necessary to meet these demands. Each application presents unique challenges, pushing the boundaries of collet technology further.

Clamping collets are vital for precision machining. Proper maintenance is essential for maximizing their lifespan. Regular cleaning is crucial. Dust and debris can accumulate, affecting performance. Use a soft brush or compressed air to clear out any buildup. Be gentle; excessive force can damage the collet.

Inspecting the collets routinely is also important. Look for signs of wear or deformation. If you notice any cracks, it’s time for replacement. Store collets in a dry place. Humidity can cause rust, leading to costly repairs. Keeping them organized can prevent accidental damage.

Lubrication is another key factor. Apply a suitable grease to moving parts. This reduces friction and enhances performance. However, too much lubrication can attract dirt. Balance is important. Proper maintenance may seem tedious, but it pays off in performance and accuracy.