- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

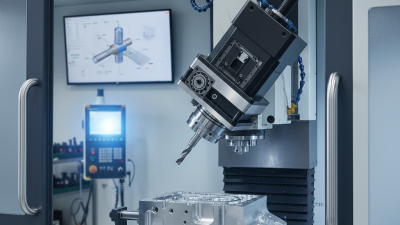

In the world of CNC machining, the Driven Angle Head stands out as a revolutionary tool. Experts like Jason Miller, a leading figure in precision engineering, argue, “The versatility of the Driven Angle Head can transform any machining process.” This highlights its importance in modern manufacturing.

Driven Angle Heads allow machinists to approach workpieces from different angles. This capability reduces the need for multiple setups, saving both time and resources. However, some machinists hesitate to adopt this technology, fearing the complexity it may introduce. It’s important to evaluate both efficiency and potential challenges.

The advantages of the Driven Angle Head are clear. It enables tighter tolerances and improved surface finishes. Yet, there is a learning curve. Adopting this tool means investing in training and practice. Some operators may struggle initially. However, with persistence, the long-term benefits outweigh early difficulties.

Driven angle heads enhance CNC machining efficiency. These attachments allow for innovative angular cuts and diverse milling operations. By facilitating additional axes of rotation, they expand the capabilities of standard CNC machines. According to a recent industry report, using driven angle heads can increase productivity by up to 40%. This pushes boundaries in design and manufacturing.

The functionality of driven angle heads lies in their ability to help machines execute complex geometries. Machinists can tackle intricate components without repositioning the workpiece. This capability reduces setup times and scrap rates. However, integrating angle heads can pose challenges. Operators must be skilled to utilize these tools effectively. Misalignment can lead to decreased precision and increased wear on the machine.

Moreover, these attachments may increase the machine's overall cost. Thus, assessing cost-effectiveness is crucial. Evaluating the investment versus potential gains is essential for companies. Evidence suggests that while initial costs are higher, the long-term benefits often outweigh these expenses. Ultimately, understanding both the advantages and limitations of driven angle heads is key to leveraging their full potential in CNC machining.

The driven angle head enhances CNC machining by allowing for complex geometries. This attachment enables multi-axis capabilities, transforming a standard machine into a versatile tool. With its precise angles, manufacturers can create intricate designs that would be challenging otherwise.

One significant benefit is the ability to machine overhangs and deep pockets. In traditional setups, these features can be cumbersome to reach. The driven angle head eliminates those limitations. It can tackle angles that are otherwise difficult, opening up design possibilities. However, achieving the right setup can be tricky. Operators may need to invest time in learning the optimal configurations.

Another key point is the reduction in setup time. By allowing for multiple operations in one setup, the driven angle head can streamline workflows. This efficiency helps reduce overall production time. Yet, mistakes can happen. Misalignments or errors in programming may occur, leading to rework. It highlights the need for proper training and careful monitoring in the machining process.

Driven angle heads can significantly impact productivity in CNC applications. They allow operators to achieve multiple angles without changing tooling. This capability saves time and reduces setup complexity. Imagine a task that requires various cut orientations; instead of stopping to swap tools, a driven angle head can effortlessly pivot to the desired angle.

This improvement not only speeds up production but also enhances efficiency. CNC machines equipped with driven angle heads can create intricate parts in fewer steps. However, it’s crucial to consider potential challenges. The initial investment might be higher, and operators need adequate training to maximize these heads' capabilities. If not properly implemented, results may fall short of expectations, leading to frustration and wasted time. Balancing the upfront cost against long-term benefits is essential in decision-making.

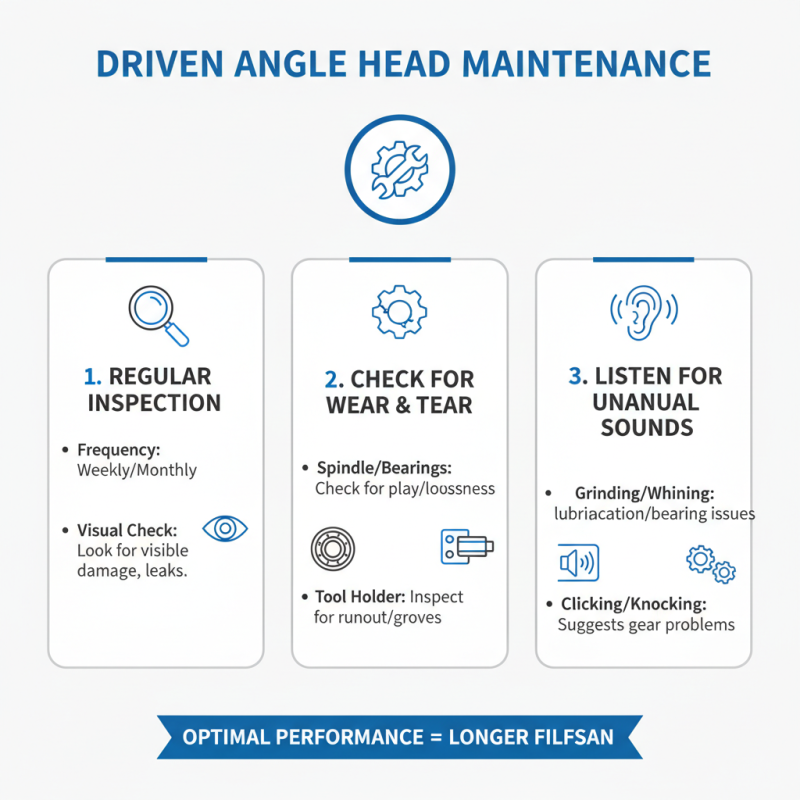

Maintenance of driven angle heads is essential for optimal performance. Regular inspection is crucial. Check for wear and tear. Look for unusual sounds during operation. These can indicate issues that need addressing.

Cleaning the angle head should be routine. Remove chips and debris after each use. Use compressed air to blow out dust. This prevents buildup that can affect precision. Lubrication is also vital. Follow the manufacturer's guidelines for oil applications.

Operators should be trained to notice signs of malfunction. Sometimes a small problem can lead to bigger issues. Keep a log of maintenance activities. This can help identify patterns over time. Learning from past mistakes is part of improvement. Regular care and timely intervention lead to better efficiency.

Driven angle heads have gained traction in various industries. Their unique capability allows for machining at different angles. This makes them valuable in sectors like aerospace, automotive, and even medical equipment manufacturing. These industries require precision and flexibility, and driven angle heads provide both.

In aerospace, for instance, complex parts demand intricate machining angles. Every millimeter matters, and errors can lead to significant costs. Driven angle heads enhance efficiency by reducing setup time. This allows for quicker production and increases output.

Tips: When integrating driven angle heads into your process, ensure proper training for your operators. A skilled team can maximize the benefits. Also, consider the compatibility with existing machinery. Not all setups will benefit equally from this technology.

The automotive industry requires diverse components, often with tight tolerances. Driven angle heads facilitate the production of these parts by enabling simultaneous operations. Businesses can achieve a high level of detail without extensive secondary processes.

Tips: Regularly maintain your angle heads to prevent wear and tear. This equipment can be an investment, but neglect can lead to issues. Always evaluate production needs. Sometimes, a different approach may yield better results.