- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

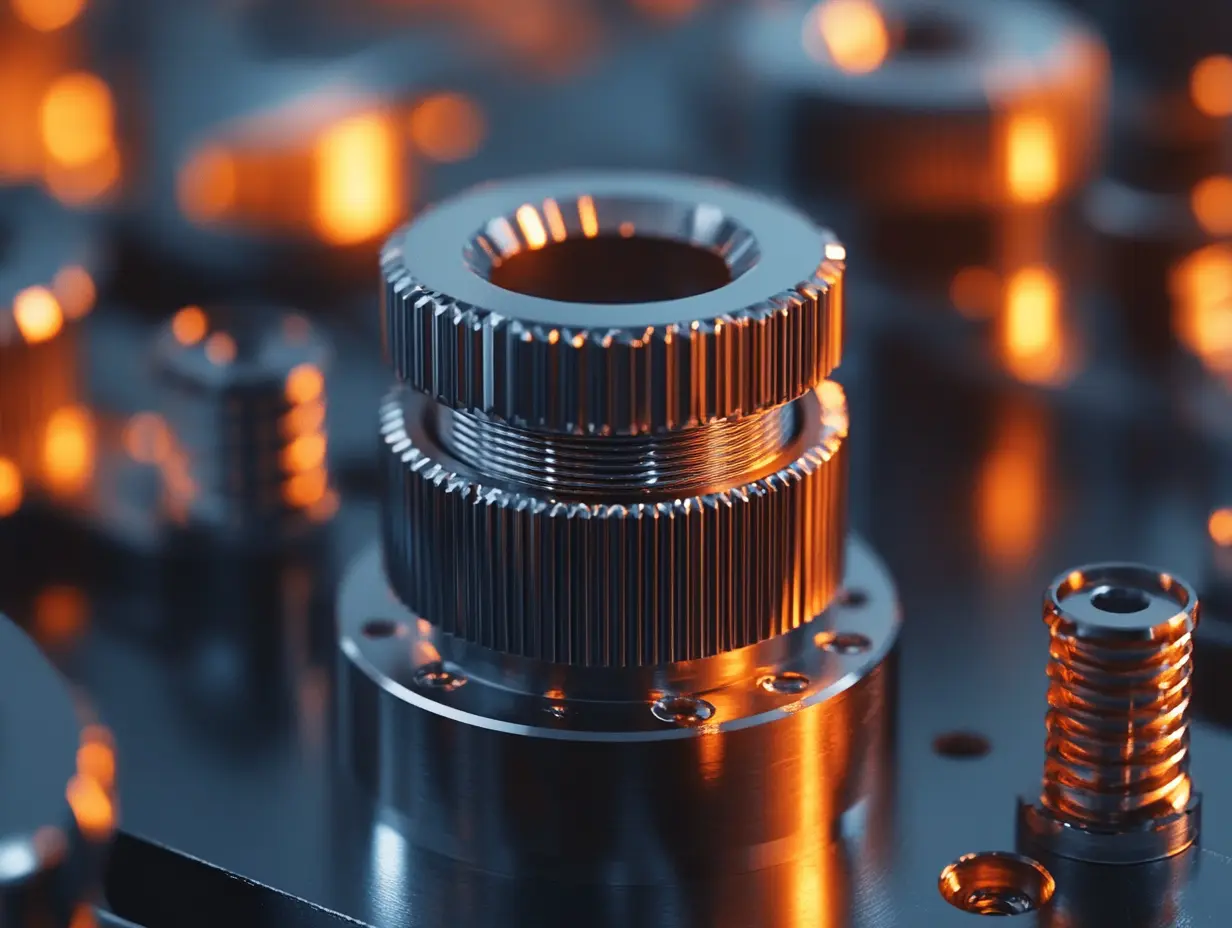

Tooling and workholding solutions are extremely important in various modern-day applications in precision engineering to achieve top performance and accuracy. Among them, the ER collet has gained huge acceptance due to its reliable gripping of a wide assortment of tool shanks with customarily low runout. Aware of productivity and precision, industries have introduced ER collets as game-changers, providing flexibility and reliability needed in any modern manufacturing process.

At Beijing Baida Technology Co., Ltd., we know that state-of-the-art tooling is highly important in the world of innovation and efficiency. Our commitment to providing quality ER collets embraces precision engineering applications across a variety of industries. In this blog, we shall look at various advantages and applications of ER collets as they relate to improved machining accuracy and operational efficiency, which in turn helps engineers and their companies attain their goals with ease.

The newly emerged ER collets have raised the standard bar as far as precision engineering is concerned. This new design was meant to source very high clamping forces and an improved level of accuracy in the case of high-speed machining, where accuracy is primal and traditional systems of collets could not suffice. ER collets create symmetry in the distribution of clamping forces over the tool, thus greatly reducing slippage, vibrations, and considering the importance of holding tool in operation during machining. In addition, ER collets are versatile enough to cater for the dynamics in machining environments. They accommodate a vast variety of forms and sizes of tools, enabling rapid tool changeover and adapting to diverse machining . As job shops go for more sophisticated machining centers, the reliability of ER will bring these collets a little further into the realm of dependability-reliable performance for optimum speed without sacrificing quality.

Precision engineering thrives on accuracy, and ER collets are critical to this measure of practice. Designed to hold cutting tools securely, ER collets are the kind of accessory that can convert any machining application, from CNC turning through milling operations, to reliable processes. The performance of ER collets means a constant flow, incorporated into strong designs that allow for minimal runout, which is ever so important when machining parts with exacting tolerances.

Toolholding systems are making progress, perhaps because modern engineering emphasizes precision. In their pursuit of efficiency, manufacturers have also given increasing importance to precision collets and the latest innovations in workholding solutions. Focus on proper tool assembly and avoiding common mishaps can further enhance the effectiveness of ER collets, allowing shops to improve their processes and uphold quality standards in their output.

Currently, the future for the ER collet technology is innovatively shaping its advancement towards more precision engineering capability. Recent trends in technology expansion are already visible in turret-adapted clamping units being designed for ER-compatible configurations. This alone demonstrates that toolholding solutions such as these will be further incorporated in the design and functionality of more advanced clamping units. Yet another innovative approach towards solid ER collets indicates their being increasingly reinforced and is another feature being added to the architectures of such devices in high-speed applications.

As modern practices, such popular methods are required to be accepted by the precision engineering industry. Further, it becomes relevant in internal celebrations concerning event anniversaries, for example, the 50th year of the original ER collet, as it constantly rekindles the innovation potential within and brings it back to the spotlight when convincing development has disrupted it in the compression of attention. Any shift toward increased complexity and/or productivity in modular tooling systems is itself a statement of what the manufacturing industry needs to respond to in terms of more demanding machining parameters and adaptability in the manufacturing process.

The right preserve and care of the ER collets are necessary to ensure long life and optimal performance for the intended precision engineering application. Regualr inspections must be conducted to identify any wear or damage that, even in minute proportions, can lead to machining results that are not up to standard. The collet cleaned and free from contaminants will also help maintain the gripping strength and accuracy.

In addition to that, proper care must also be given to ER collet-related mistakes like improper tool assembly and inadequate tightening. Educating your staff on the proper way of using and maintaining collets can really help to avoid errors and prolong their lifetime. Engineers become all the more productive and achieve better results on their projects when they proactively care for ER collets.

Upright ER collets are indispensable items in precision engineering. ER collets are well-known for their ability to hold tightly on different types of tools. The collets have an unusual design structure that consists of a series of nested, radially expandable elements that provide an even distribution of clamping force over the entire tool surface. The low runout featured by this design helps enhance machining accuracy, which often is paramount in the high-performance application.

ER collets are multifunctional; hence many manufacturers will use them for various purposes. Since they will fit into a multitude of tooling systems, they will work with odd tool geometries for a multitasking environment, inclusive of those with advanced zero-point working-holding systems. With a shift in the industry toward more integrated and modular tooling solutions, effective operation of ER collets has become critical in meeting modern precision engineering demands.

Material considerations for ER collets in precision engineering require an understanding of how materials affect performance and durability. Typically, ER collets are made out of chrome vanadium steel and high-grade alloys that represent a balance between strength and flexibility. These materials act with minimum distortion during tightening, allowing for a consistent clamping force and better precision.

Maintenance and proper assembly can significantly diminish the common mistakes when using ER collets. Good practice is to keep the components clean and free from debris to prevent vibration and promote efficient performance. Movement towards modular tooling translates into concrete advancements for the ER collet system, making it very much essential for modern machining needs. With the investment in top-quality materials and practices, engineers are increasing the benefits of ER collets for their jobs.

ER collets have made a great change in the way precision engineering has been carried out in CNC machining. These collets provide high clamping accuracy and stability which makes them suitable for clamping cutting tools. Over time, as the industry changes, the requirement for reliable toolholding systems has brought up innovations such as the solid ER collet to improve the performance of machining application.

Over the past few months, the viability of all tool assembling and site maintenance for effective application of ER collets has been emphasized. Understanding the common mistakes that operators can make such as insufficient cleaning and incorrect tightening enables one to reap the full benefits of these tools. Business case development and toolholding solutions keep changing, like the turret-adapted clamping unit expansion, in response to the growing need for more robust systems that withstand today's demanding environments in manufacturing.

A little analysis would convince any observer that ER collets, becoming a more reliable tool-holding system in precision-engineering applications with several distinct advantages over other tool-holding methods, also add to the operational flexibility and efficiency of clamping a wide range of tool shank sizes. This adaptability gives ER collets the preferred choice in accuracy-demanding jobs.

In comparison, other tool holding systems, assuming Weldon flats, would somewhat be regarded as tried and tested but their drawbacks in grip versatility and changeover ease really slow down workflow. The recent development of turret-adapted clamping units with solid ER collets points toward major developments in tool-holding technology, emphasizing the need for a system suited to present demands but also geared toward prospects for developing machining processes. Responding to demands from manufacturers for ever more productive solutions, ER collets are the most adaptable and acceptable option that can confidently ensure precision and productivity.

By connecting flexibility with precise control, ER collets increase the performance and stability of the tool in precision engineering. They offer an excellent gripping ability on cutting tools and thus minimize vibration and tool chatter during operation. Particularly for high-speed machining applications, precision becomes essential. Thus manufacturers transiting to ER collets in preference to traditional tooling systems are becoming a trend towards efficiency with precision.

New developments in toolholding technologies show the importance of the ER collet. Innovations such as new improvements to zero-point workholding systems supplement the reliability of ER collets and provide further assistance to keep precision over several other machining applications. With the continuing changes of the industry, the integration of ER collets with more state-of-the-art systems will most probably define the future of efficient manufacturing processes.

ER collets are tool holding devices designed to securely hold cutting tools in place, ensuring high accuracy and precision in various machining applications.

Precision is crucial in engineering because it directly affects the quality of manufactured components, especially those requiring exact tolerances.

ER collets offer exceptional clamping accuracy and stability, resulting in minimal runout and allowing for precise machining operations.

ER collets are widely used in CNC machining for securing various cutting tools, enhancing operational efficiency and flexibility.

Common mistakes include improper tightening of the collet and inadequate cleaning, which can compromise the effectiveness of the toolholding system.

ER collets provide better grip versatility and ease of changeover compared to traditional systems like Weldon flats, making them a more efficient choice for precision engineering.

Recent advancements include the development of solid ER collets and turret-adapted clamping units, which enhance performance and accommodate the demands of modern manufacturing.

Proper tool assembly and maintenance are essential to fully leverage the advantages of ER collets and to maintain high-quality standards in machining processes.

Their high adaptability to a wide range of tool shank sizes and their ability to provide a reliable, precise holding system make ER collets a popular choice among manufacturers.

By ensuring precision and reducing errors during tool setup, ER collets help optimize machining processes, ultimately leading to improved productivity and quality in output.