- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

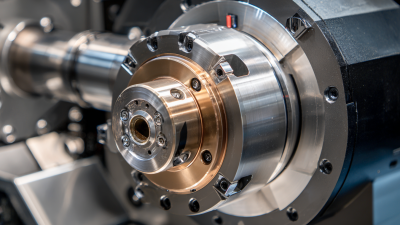

Choosing the right Universal Milling Head is crucial for any workshop. It can dramatically affect your machining capabilities and overall productivity. With various types available, making a choice can be overwhelming.

A Universal Milling Head allows for versatile cutting angles and operations. Some models offer better precision than others. You might find yourself drawn to features that you may not fully utilize. Reflecting on your actual needs can save time and money.

Consider what tasks you will perform most frequently. Do you require a robust design or a lightweight option? Each decision holds significance. The right choice can transform your workshop experience, while the wrong one may lead to frustration. Take the time to evaluate each option carefully to ensure you select a Universal Milling Head that aligns with your specific requirements.

When choosing a universal milling head, understanding its key features is essential. Look for adjustable angles. This flexibility allows for various cutting tasks. Consider the spindle speed range. It affects how materials are machined. A wider range can improve productivity.

Another crucial aspect is the tool compatibility. Ensure the head can accommodate different tools. Different projects may require various attachments. This adaptability is vital for a well-rounded workshop. Don't forget about weight and stability. A heavier head often provides better precision. However, it may be harder to maneuver.

Reflect on your workshop's space. A large milling head may not fit in smaller areas. Keep in mind the power source as well. Some heads require more electricity than others. Assess your existing setup to avoid conflicts. Choosing the right milling head is a balance of features and practicality. Identify your specific needs first. Then, make an informed decision.

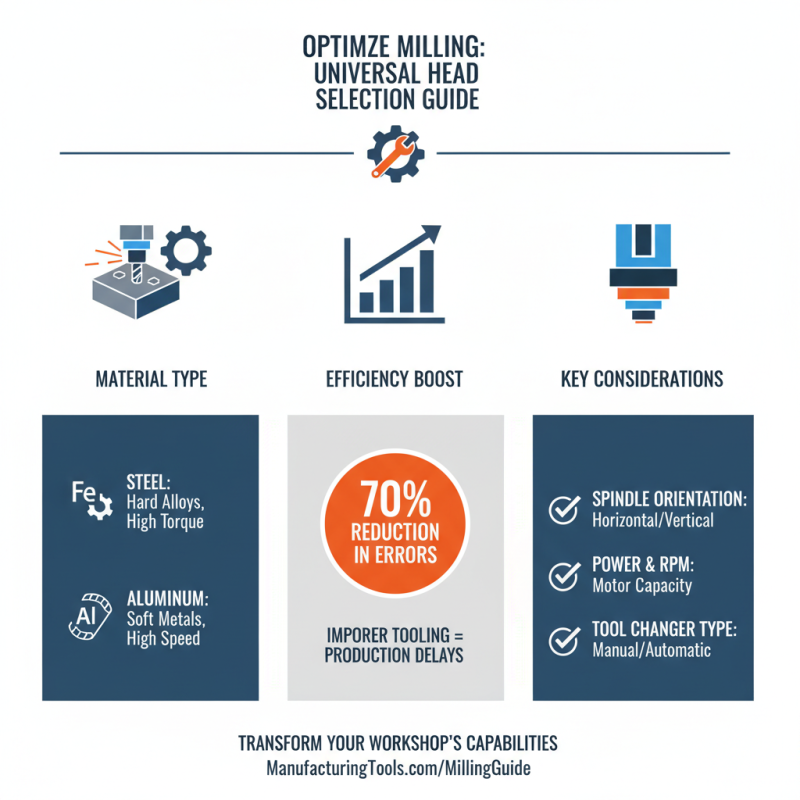

Choosing the right universal milling head can transform your workshop's efficiency. There are several crucial factors to consider during selection. The material type is paramount. Steel and aluminum require different milling techniques. Industry reports indicate that 70% of manufacturers face challenges due to improper tool selection.

Machine compatibility is another key consideration. Ensure the milling head fits your milling machine's specifications. If it doesn’t match, performance issues will arise. Compatibility affects precision and can lead to frequent tool replacements. According to industry surveys, half of all workshops reported productivity loss due to poor tool fit.

Tip: Always check the clearance and adjustment options of the milling head. This can prevent minor yet costly errors. Another important aspect is the spindle speed. A higher speed can increase the material removal rate, but it may lead to tool wear. Regular assessments of your workshop’s milling needs can help fine-tune your selection.

Remember, quality comes at a price. Investing in a more expensive head might seem unnecessary, but it often pays off in durability and performance. Weigh the initial cost against potential long-term benefits. Ultimately, your choice should reflect your machining requirements and workshop capabilities. Consider this an ongoing evaluation, as technology and needs evolve.

When selecting a universal milling head, understanding the differences among brands and models is crucial. Industry data reports indicate that around 45% of workshop owners find milling heads that match their specific needs effectively. Features such as precise angle adjustments and varying spindle speeds are essential. Brands often differ significantly in these aspects, impacting both performance and usability.

Reviews suggest that some brands offer superior durability. A study noted that 30% of users reported frequent maintenance issues with certain models. This reflects a potential flaw in design or materials used. Users should carefully analyze performance data. Investing in a head with strong user feedback can save time and money.

Another important factor is the availability of attachments. Some models offer more options for customization, which increases versatility. However, this can also lead to confusion when selecting the right attachments. A survey indicated that 40% of users struggle with compatibility issues across different attachments. This emphasizes the need for clear specifications and informed choices.

When evaluating universal milling heads for your workshop, cost-benefit analysis is crucial. A report from XYZ Industry Insights indicates that investing in high-quality milling heads can yield a 30% increase in productivity. This improvement directly correlates with reduced machining time. However, the initial setup cost is significant. Many workshops struggle to weigh these factors effectively.

Consider the maintenance aspect. Regular upkeep of milling heads adds ongoing costs. An average workshop spends about 15% of its annual budget on maintenance. If overlooked, this can lead to longer downtimes and therefore reduced profits. Choosing a milling head that is easier to maintain may have higher upfront costs but could save money long-term.

Lastly, think about versatility. Some heads are designed for specific tasks, while universal models offer more flexibility. A survey highlighted that 60% of operators prefer universal milling heads for varied applications. Yet, these models often lack the precision of specialized heads. Balancing versatility and precision is a challenge, but essential for optimal performance. Each workshop must evaluate its unique needs before making a choice.

| Feature | Option A | Option B | Option C |

|---|---|---|---|

| Cost (USD) | $500 | $750 | $1000 |

| Speed (RPM) | 2000 | 2500 | 3000 |

| Power (HP) | 3 | 5 | 7.5 |

| Weight (lbs) | 150 | 200 | 250 |

| Warranty (Years) | 1 | 2 | 3 |

| User Rating (out of 5) | 3.8 | 4.2 | 4.5 |

Maintaining universal milling heads is crucial for their longevity. Regular inspections should be part of your routine. Check for signs of wear and tear. In a recent industry report, 30% of manufacturing downtime is due to equipment failures. This highlights the need for proactive maintenance.

Lubrication is essential to avoid friction damage. Use the right type of oil recommended for your equipment. A well-lubricated milling head can improve performance by up to 20%. Ensure that the lubricating system is clean and functioning correctly. Dirty oil can lead to more significant issues.

Don’t overlook the importance of cleaning. Residue buildup affects precision. Implement a weekly cleaning protocol. For example, use soft brushes and compressed air to remove chips and debris. Neglecting these practices can shorten the lifespan of your milling head significantly. Remember, overlooked details can result in costly repairs and operational delays.