- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

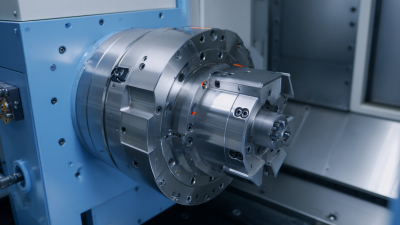

In the competitive landscape of manufacturing, the choice of tooling can significantly impact performance and efficiency. Among the various options available, the Rubber Flex Collet has emerged as a prominent choice due to its unique advantages over traditional collet designs. According to a report by the National Tooling and Machining Association, proper tool and collet selection can enhance machining accuracy by up to 30% and reduce downtime by nearly 25%. The flexibility and adaptability of Rubber Flex Collets allow them to securely grip a wide range of workpiece shapes and sizes, making them ideal for dynamic manufacturing processes. As industries increasingly prioritize precision and efficiency, understanding how to select the right Rubber Flex Collet becomes crucial for optimizing productivity and achieving operational excellence. This blog will explore the benefits of Rubber Flex Collets and provide guidance on how manufacturers can make informed choices to elevate their performance.

When selecting rubber flex collets for your manufacturing needs, several critical factors come into play that can significantly impact performance and efficiency. First and foremost, it is essential to evaluate the specific requirements of your application. Consider the material being machined and the type of tooling involved. For instance, different rubber compounds offer varying levels of grip and flexibility, which directly influence the precision and stability of your machining operations.

Another key aspect to consider is the size and compatibility of the collet with your machinery. Ensuring a proper fit minimizes vibration and improves tool life. It is also beneficial to think about the collet's clamping range—an adaptable collet that can grip a variety of tool sizes may enhance versatility on the shop floor. Additionally, pay attention to each collet's operational temperature and wear resistance to ensure that it can withstand the rigors of your specific manufacturing environment, ultimately leading to increased productivity and reduced downtime.

This chart illustrates the important factors to consider when selecting Rubber Flex Collets for manufacturing. Each factor is rated on a scale of 1 to 10 based on its importance, aiding in optimal performance and efficiency.

When selecting the right rubber flex collet for manufacturing applications, it’s crucial to understand the various types available on the market. Rubber flex collets are designed to securely hold tools or workpieces while allowing for some flexibility, accommodating variations in size and shape. According to a report by the National Institute of Standards and Technology, the market demand for precision tooling has seen an annual growth rate of 3.5%, highlighting the importance of choosing the right collet to enhance productivity and minimize machining errors.

The main types of rubber flex collets include standard, heavy-duty, and custom designs. Standard collets are versatile and suitable for most general applications, while heavy-duty options are built to withstand increased stresses, ideal for high-torque settings. Custom rubber flex collets can be tailored to specific sizes and requirements, providing a unique solution for specialized manufacturing processes. A study by the Manufacturing Institute found that more than 60% of companies utilizing custom tooling reported significant efficiency improvements, underlining the value of selecting the appropriate collet type for optimal performance in manufacturing settings.

When selecting a rubber flex collet, understanding how material composition impacts performance is crucial for optimizing manufacturing processes. The choice of materials—ranging from traditional rubbers to innovative composites—can significantly influence the collet's durability, flexibility, and overall efficiency. For instance, studies have indicated that advanced elastomers can enhance grip and provide superior vibration dampening, leading to improved machining accuracy. According to a report by the Society of Manufacturing Engineers, the right material selection can lead to a 20% increase in tool lifespan, reducing costs related to tool replacement and downtime.

Recent advancements in engineered composite materials, particularly those derived from fungal biorefineries, are reshaping the landscape of manufacturing components, including rubber flex collets. These sustainable materials, created by upcycling agricultural waste into high-performance composites, offer a viable alternative to traditional plastics and foams. Research shows that these mycelium-based composites exhibit comparable tensile strength and flexibility, while also being eco-friendly. This innovation not only aligns with growing sustainability goals in the manufacturing sector but also meets performance needs, indicating a potential shift in how manufacturers approach collet material selection for optimal performance and efficiency.

When working with Rubber Flex Collets, proper installation becomes crucial for ensuring optimal performance and efficiency in manufacturing. Start by thoroughly cleaning the collet and the tool holder to remove any debris or contaminants that may interfere with the fit. Ensure that the collet aligns correctly with the tool's shank, and carefully tighten it to the manufacturer's specifications. Avoid overtightening, as this can damage the collet or affect the tool’s concentricity.

Maintenance is equally important to prolong the life of your Rubber Flex Collets. Regularly inspect the collets for signs of wear or damage, such as cracks or excessive deformation. Keep them lubricated as per the manufacturer’s guidelines to maintain flexibility and prevent brittleness. Additionally, storing the collets in a dry, dust-free environment will help avoid contamination and deterioration. With these installation and maintenance tips, you can ensure your Rubber Flex Collets perform at their best, leading to improved manufacturing efficiency and product quality.

When selecting rubber flex collets for manufacturing, avoiding common mistakes can significantly enhance performance and efficiency. One prevalent error is not considering the specific application requirements. Different machining tasks demand varying levels of flexibility, gripping force, and precision. Failing to match the collet to the exact needs can lead to poor part finish, increased cycle times, and even machine damage over time.

Another mistake is neglecting the proper sizing and compatibility with existing machinery. Collets that do not fit perfectly may slip or not secure the workpiece adequately, leading to operational inefficiencies. It's crucial to verify the dimensions and specifications of both the collet and the spindle to ensure a seamless fit. Additionally, overlooking the importance of material quality can hinder performance. Investing in high-quality rubber flex collets not only ensures better durability but also contributes to reduced maintenance costs and prolonged equipment life. Prioritizing these factors can help manufacturers achieve optimal results while minimizing unnecessary downtime and expenses.

| Dimension | Description | Common Mistakes | Best Practices |

|---|---|---|---|

| Material Type | Different rubber compositions affect flexibility and durability. | Choosing solely based on price without evaluating material quality. | Assess material specifications and performance ratings. |

| Size and Fit | Proper size ensures optimal grip and minimizes wear. | Selecting a collet based on general recommendations without verifying dimensions. | Always measure and verify required specifications before choosing. |

| Collet Design | Different designs cater to various machining needs. | Overlooking the importance of collet design in specific applications. | Understand the operational environment and choose accordingly. |

| Performance Rating | Performance ratings reflect reliability under various conditions. | Neglecting to check performance ratings before purchase. | Review performance ratings and select products with proven track records. |

| Compatibility with Machinery | Ensure collets are compatible with existing machines. | Ignoring machinery specifications and compatibility. | Consult machinery specifications and collet compatibility before purchasing. |