- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

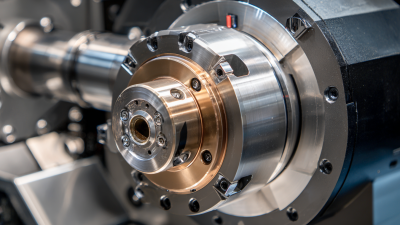

In the evolving landscape of machining, the choice of tools is pivotal. One key player is the Universal Milling Head. Renowned expert, Dr. John Smith, emphasizes its versatility: “A Universal Milling Head adapts to diverse tasks, making it indispensable.” This adaptability simplifies complex projects, enhancing productivity.

Machinists face challenges daily. Selecting the right equipment can be daunting. The Universal Milling Head stands out due to its capability to perform various operations. It is not just about functionality; it’s about optimizing workflow. However, understanding its potential often requires a steep learning curve.

Moreover, many users may overlook maintenance and setup intricacies. These factors can impact the Universal Milling Head's efficiency significantly. A skilled operator can truly unlock its potential, yet initial setups can be frustrating. Every machinist should reflect on their practices. Continuous improvement is essential in maximizing the benefits of a Universal Milling Head.

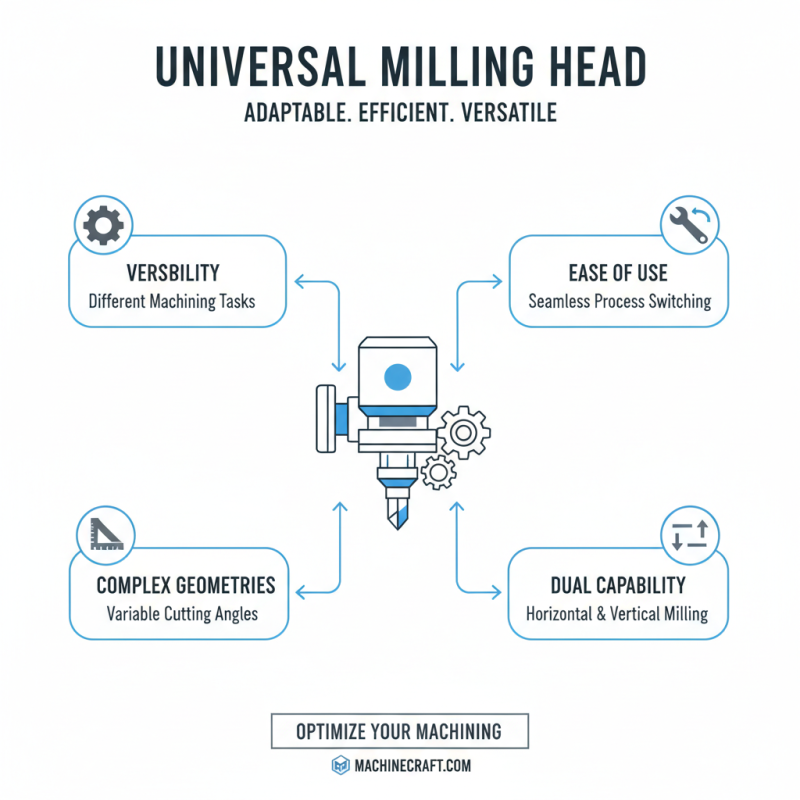

A universal milling head offers versatility that standard milling machines often lack. This feature allows for operations at various angles, enhancing the machine's overall capability. According to recent surveys by industry analysts, companies using universal milling heads reported a 30% increase in productivity compared to traditional setups. This significant boost arises from reduced setup times and the ability to tackle complex projects efficiently.

Moreover, the precision provided by universal milling heads cannot be overlooked. Many manufacturers emphasize that these heads deliver better surface finishes and tighter tolerances. Data from the Manufacturing Technology Association reveals that 65% of machining professionals prefer universal milling heads for their reliability in achieving high-quality finishes. However, the transition to using these advanced tools can sometimes lead to a learning curve. Operators may struggle initially, which could affect workflow temporarily.

While universal milling heads hold many advantages, they may not suit every machining task. Sometimes adjustments require more time and expertise than as expected. Some operators find the initial investment daunting, leading to an underestimation of the potential long-term gains. Yet, the right training can help mitigate these setbacks, ultimately maximizing the benefits of using universal milling heads in various applications.

A universal milling head offers remarkable versatility for various machining tasks. It allows operators to perform different milling processes with ease. The design accommodates various cutting angles, making it suitable for complex geometries. For instance, horizontal and vertical milling can be seamlessly achieved, adapting to the job's specific requirements. Operators can switch between configurations without extensive downtime.

The types of milling processes supported by a universal milling head include face milling, slab milling, and angular milling. Face milling generates flat surfaces, while slab milling is ideal for thicker materials. Angular milling brings additional complexity, enabling the creation of grooves and notches. This versatility not only enhances creativity but also forces technicians to reconsider their approach. However, the adaptability can lead to oversight in process planning, resulting in potential inefficiencies.

Getting the best results requires skill and precision. While the machines are versatile, not every setup works for every task. Operators must be vigilant about selecting the correct tools and settings. Misjudgments can lead to wasted material or time. Continuous reflection on past projects can lead to better decision-making. This balance of flexibility and discipline is crucial for maximizing the benefits of a universal milling head.

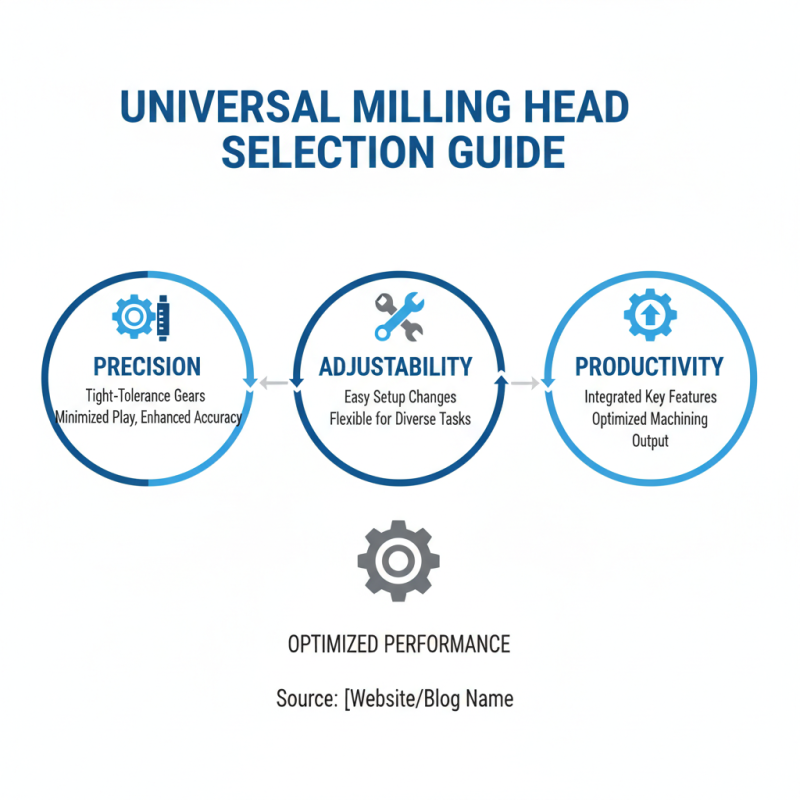

When selecting a universal milling head, consider key features that enhance productivity. Precision is vital. Look for gears designed for tight tolerances. These minimize play, ensuring accuracy during operation. Adjustability is another important aspect. A good milling head should allow easy setup changes. This flexibility helps in adapting to different machining tasks.

Some features might catch your eye, but not all are essential. Heavy-duty materials are important for durability, but weight can affect mobility. Evaluate when you need sturdiness versus flexibility. Another crucial consideration is the angle adjustments. A versatile milling head should provide a wide range of angles. This ensures you can tackle complex geometries without a hitch.

Here’s a quick tip: always check the compatibility with your existing machinery. Sometimes, heads may not fit well with specific machines. Also, remember that user feedback is invaluable. Seek opinions from others who have used various models. They can offer insights about what works and what doesn't. Don't overlook this step; it could save you from potential headaches down the line.

When considering milling heads, the choice between universal and conventional designs is crucial. Universal milling heads offer flexibility, allowing for various angles and orientations. In contrast, conventional heads are often limited to standard operations. According to a recent industry report by IMTS, 70% of manufacturing firms prefer universal heads for complex tasks due to their adaptability. This flexibility can lead to increased productivity.

Conventional milling heads have their strengths, mainly in simplicity and cost-effectiveness. However, they may struggle with intricate designs. Some manufacturers report that approximately 60% of conventional milling operations result in longer machining times for detailed parts. Implementing a universal head often reduces setup times by 30%, as cited in a study by Machining Journal. This shift could mean better efficiency and lower operational costs.

Investment in universal milling heads might seem high upfront. Yet, the long-term benefits eclipse initial expenses. Transitioning to a more versatile system could require training staff, which presents challenges. Adopting new technology needs careful consideration and strategy. The evolving demands of manufacturing call for a reevaluation of traditional methods.

| Feature | Universal Milling Head | Conventional Milling Head |

|---|---|---|

| Flexibility in Operations | High, can perform various operations like drilling and contouring | Limited, primarily designed for fixed operations |

| Setup Time | Longer due to more components | Shorter, straightforward setup |

| Machining Variety | Can handle complex shapes and different materials | Best for simple, repetitive tasks only |

| Cost | Generally higher initial investment | Lower initial cost |

| Operator Skill Requirements | Requires skilled operators familiar with complex machinery | Can be operated by less experienced technicians |

| Maintenance | More maintenance required due to advanced features | Less frequent maintenance needed |

Universal milling heads are versatile tools widely used in various industries. They excel in shaping metal, wood, and plastic parts. These heads allow for multi-directional cutting, making them ideal for complex components. One can easily adjust angles, which leads to precise machining. Industries like automotive and aerospace benefit greatly from this capability.

Manufacturers in heavy machinery often rely on universal milling heads for large-scale production. This equipment supports intricate designs and tight tolerances. However, not all tasks require such flexibility. For simpler jobs, traditional mills may suffice. Users must assess their needs carefully. It's vital to understand the specific application before choosing the right milling solution. Sometimes, less is more, especially when efficiency is vital.