- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right tools for your projects can be challenging. One particularly versatile tool is the Adjustable Angle Head. This tool offers flexibility in various applications, from woodworking to metalworking. Its ability to adjust angles simplifies many tasks.

When selecting Adjustable Angle Heads, consider your project's specific needs. Different projects may require varied angles and accuracy. Look for a model that fits your work style. However, not every Adjustable Angle Head will meet expectations. Some may lack durability or precision, requiring you to reassess your choices.

Ultimately, the decision hinges on thoughtful evaluation and hands-on testing. Don't rush the selection process. Experiment with different options to find what truly suits your requirements. In the end, the right Adjustable Angle Head can make a significant difference in your work quality and efficiency. Reflect on your choices to improve future projects.

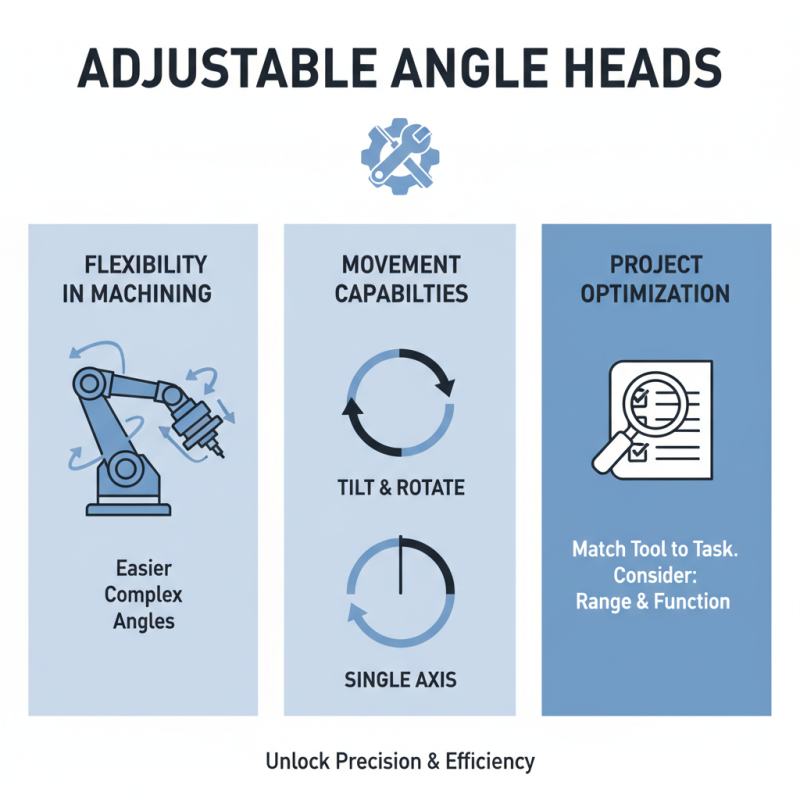

Adjustable angle heads serve a crucial role in various projects. They enable flexibility in machining, making complex angles easier to achieve. When you utilize these tools, consider their range of adjustment. Some heads tilt and rotate, while others might only offer one axis of movement. Understanding these functionalities is key to choosing the right tool.

While working on a project, alignment is critical. You may find that some adjustable heads offer better precision than others. An imprecise angle could lead to flawed work. This reality highlights the importance of testing different models. Spend time assessing how each head performs under your specific conditions. Not all designs fit all tasks perfectly.

Moreover, it's essential to consider the ease of setup. Some adjustable angle heads are user-friendly, while others might require extensive adjustments. If a tool complicates your workflow, it’s worth reevaluating your choice. A project can often hinge on these small, seemingly trivial details. Open your mind to the learning process involved in selecting the right head for your needs.

When selecting adjustable angle heads, several key factors should guide your decision. Compatibility with your machinery is crucial. For instance, different machines require specific attachments. A mismatch can lead to inefficiencies or even damage. According to industry reports, over 30% of machine downtime results from improper tooling choices.

Another important aspect is the range of angles available. Adjustable angle heads can typically handle various angles, often up to 90 degrees. However, some models may limit usability in certain projects. In research, engineers found that projects requiring versatility often benefit from heads that adjust beyond standard angles. Ensuring you have the right range can significantly influence your project outcomes.

Material quality impacts durability and performance. Many adjustable angle heads are made from high-strength alloys. However, not all materials withstand heavy use. A study showed that 40% of non-branded products failed prematurely compared to established options. Choosing wisely can save both time and money in the long run.

When exploring adjustable angle heads, understanding the various types available is essential. According to a recent industry report, nearly 45% of manufacturers prioritize versatility in their projects. This demand drives innovation in adjustable angle head designs. Users need options that balance flexibility and precision.

Rotary angle heads are popular among machinists for their ability to cut at multiple angles. They allow for greater machining flexibility. They are easy to attach and detach, reducing setup time. However, their complexity can sometimes lead to calibration challenges.

In contrast, fixed angle heads suit specific applications better. Their robust design offers durability. Yet, they lack the adaptability of rotary models. It’s crucial for professionals to analyze project requirements carefully. The wrong choice can lead to excess downtime or unanticipated costs. Balancing between these types requires careful thought and planning. Making an informed decision can streamline workflows, ultimately enhancing productivity.

When choosing adjustable angle heads, tool compatibility is crucial. Not all tools work well with every angle head. You must ensure that your adjustable head fits your existing tools seamlessly. This can prevent unnecessary frustration during your projects.

Consider the specifications of your tools. Look at the size and power ratings. Ensure the angle head aligns with these parameters. Some heads may appear universal but can fall short in practice. Always read user reviews when possible.

**Tips:** Check the dimensions before purchasing. That extra angle can make a difference. Test the connection before starting your work. It can save time. Remember, a poor fit can lead to misalignment and wasted materials.

Additionally, reflect on your skill level. If you're a beginner, a complex angle head may be overwhelming. Simplicity can lead to better results in your projects. Prioritize ease of use. An adjustable head should enhance your tool, not complicate it.

Choosing the right adjustable angle head can elevate your project’s precision. The market offers various models, but brand reputation matters. Reports indicate that adjustable angle heads enhance production efficiency by over 20%. This is crucial for industries reliant on precision machining.

Top performers in the adjustable angle head category often feature multiple angle settings. Some models allow a range from 0 to 180 degrees. Engineers appreciate this flexibility for intricate designs. However, choosing a low-cost option might lead to subpar results. This can result in more errors in the machining process.

Durability is another critical factor. Models made with high-quality materials tend to have a longer lifespan. A recent study showed that 65% of users experienced better performance with premium options. Yet, some users find it hard to justify the cost. Balancing price and performance is a common dilemma in the industry. Finding reliable reviews and user feedback is essential to making an informed choice.

| Model | Adjustable Angle Range | Material | Weight | Price Range |

|---|---|---|---|---|

| Angle Head A | 0° to 90° | Aluminum | 1.5 kg | $100 - $150 |

| Angle Head B | 15° to 120° | Steel | 2.0 kg | $120 - $180 |

| Angle Head C | 30° to 160° | Titanium | 1.8 kg | $150 - $220 |

| Angle Head D | 0° to 180° | Carbon Fiber | 1.2 kg | $200 - $300 |