- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right Air Water Separator Filter is crucial for maintaining equipment performance. These filters remove moisture and contaminants from air systems. A good filter prolongs the life of your machinery and enhances efficiency.

When selecting an Air Water Separator Filter, consider your specific needs. Not all filters work the same for every application. Think about the size, filtration level, and durability of the filter. For instance, industrial-grade filters differ from those meant for smaller systems.

Creativity in decision-making is essential. You'll face challenges in finding a filter that perfectly matches your requirements. Some filters might be too expensive or insufficient for your application. Reflecting on your choices can lead to better results. Ultimately, the right Air Water Separator Filter can significantly impact your system's performance in both cost and efficiency.

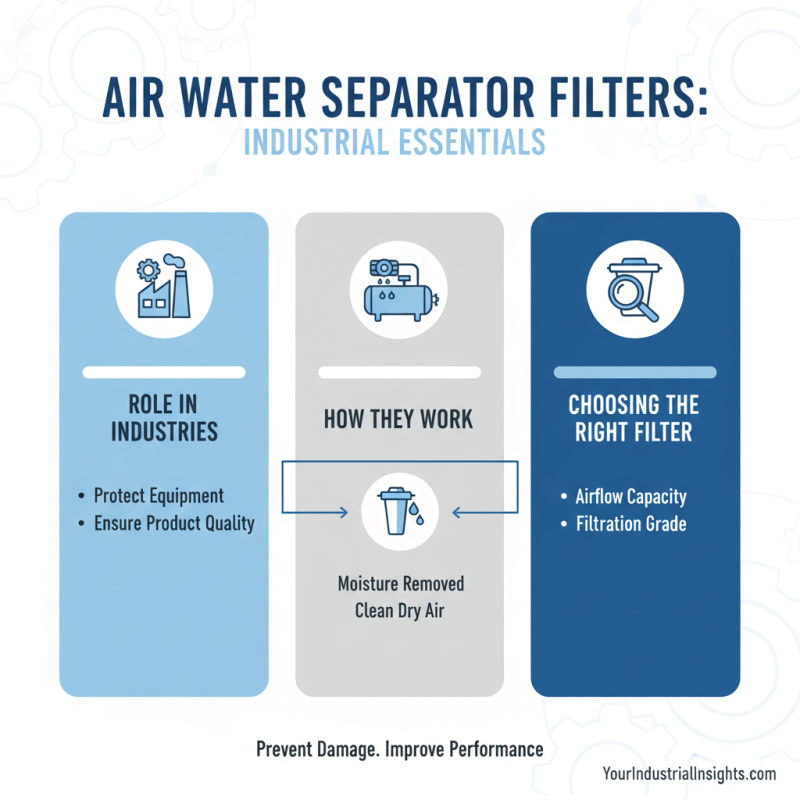

Air water separator filters play a crucial role in various industries. They remove moisture from compressed air systems. This moisture can harm equipment and affect product quality. Understanding how these filters work can help you choose the right one for your needs.

These filters use a combination of physical separation and filtration. As air flows through, water droplets coalesce and drop out. Various designs exist, including coalescing filters and centrifugal separators. Each type has unique benefits, but they aim for the same result: clean, dry air.

**Tips:** Monitor your system regularly. Check for any signs of water accumulation. Replace the filters as recommended to ensure effectiveness.

Choosing the right air water separator filter isn’t easy. You may find it challenging to determine the correct specifications. Think about your environment and application demands. If in doubt, consult an expert. Understanding the functionality is key to making an informed decision.

When selecting an air water separator filter, key specifications play a critical role. Efficiency is one of the most important factors. Reports indicate that efficient filters can remove up to 99% of moisture from compressed air systems. However, it is crucial to consider the specific needs of your application. Some industries require higher moisture removal rates than others.

Filter capacity is another essential specification. This capacity often depends on the air volume and the flow rate of the system. Studies show that underestimating capacity can lead to system failures or maintenance issues. You could face unexpected costs if the separator is not adequately sized for your system's demands.

Lastly, maintenance requirements shouldn’t be overlooked. Regular maintenance is vital for optimal performance. Industry insights suggest that neglecting maintenance can reduce efficiency by up to 30%. Filters should have clear guidelines on replacement intervals. Understanding these specifications will help ensure you choose the right air water separator filter for your needs.

| Specification | Details |

|---|---|

| Flow Rate | Up to 1000 CFM |

| Filtration Efficiency | 99% for particles 5 microns and larger |

| Operating Pressure | 10-150 PSI |

| Tank Size | 20 Gallons |

| Material | Corrosion-resistant aluminum |

| Drain Type | Automatic drain valve |

| Dimensions | 24" x 18" x 12" |

| Weight | 50 lbs |

| Temperature Range | -10°F to 150°F |

When selecting an air water separator filter, efficiency ratings play a crucial role. These ratings determine how effectively contaminants are removed. According to industry reports, filters with higher efficiency ratings can remove up to 99% of water and particulates. This is particularly important in systems that deal with compressed air and hydraulic fluids.

A filter with a low efficiency rating may allow moisture to pass through, leading to system corrosion and inefficiencies. In fact, a study indicated that even a 0.5% increase in water can significantly degrade equipment performance and lead to costly repairs. Regular maintenance and the choice of filters must be critically evaluated.

Some filters appear efficient but offer poor performance in real-world applications. Users should consider both specified ratings and feedback from actual usage. Not every filter will meet expectations in every environment. Testing and adapting your choices can lead to better outcomes.

Air water separator filters play a crucial role in various industries. They are commonly used in manufacturing and processing plants. These filters help to remove moisture from compressed air before it enters critical systems. Moisture can cause significant damage to machinery. This is a common issue in environments where humidity is high.

In food and beverage industries, air water separators are essential. They ensure that air used in packaging is free from water. This prevents contamination of products. Similarly, in automotive and aerospace sectors, quality air supply is vital. Here, the filters protect pneumatic tools and equipment. However, organizations often underestimate the need for regular maintenance of these filters. Neglecting this can lead to reduced efficiency.

Another key application is in HVAC systems. Air water separators help maintain air quality in buildings. They reduce the risk of mold and mildew growth. The challenge lies in selecting the right filter type for specific needs. Businesses often struggle with this decision. Understanding the particular requirements of their operations is necessary for proper selection.

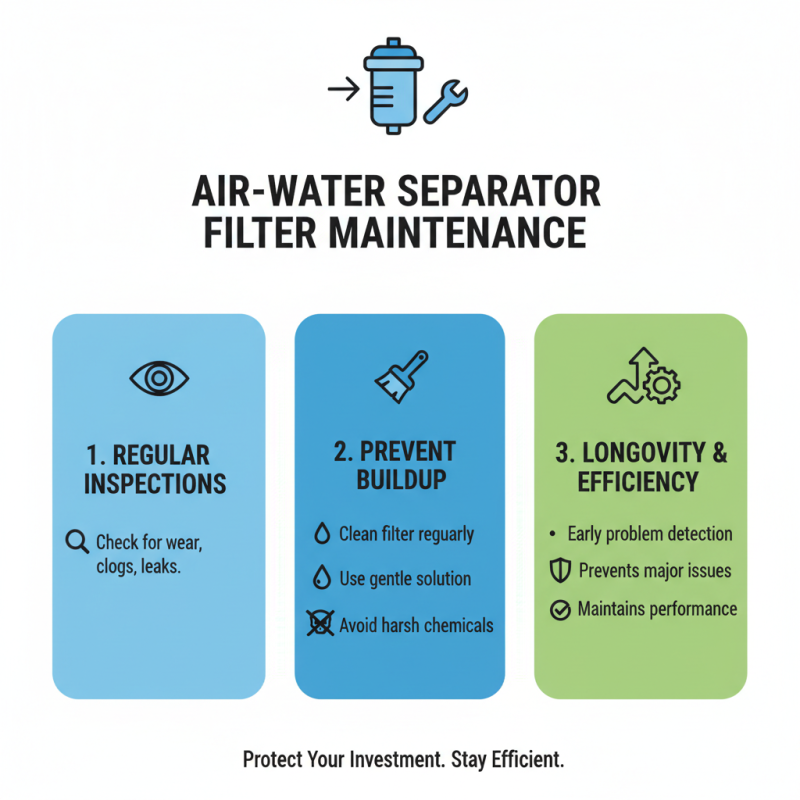

Maintaining your air water separator filter is crucial for its longevity. Regular inspections help identify early signs of wear. Check for any clogs or leaks. Even minor issues can lead to major problems later on. Clean the filter regularly to prevent buildup. Use a gentle cleaning solution; harsh chemicals can damage the filter materials.

After extensive use, replacement parts may be necessary. Don’t wait for a breakdown to act. Look for damaged components during each inspection. Keeping spare parts on hand can save time and frustration. It's also important to consider the environment. High humidity can affect performance. Ensure proper installation for efficient operation.

Forgotten details can lead to neglect. Sometimes, we overlook simple tasks. Set reminders for maintenance checks. Document the maintenance history. This helps track performance trends over time. Remember, a well-maintained filter works better and lasts longer. Taking these small steps can make a significant difference.