- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the Right Angle Milling Head for your machining needs is crucial. The right tool can significantly enhance productivity. According to a report by Market Research Future, the global milling tools market is expected to reach USD 7.2 billion by 2025. This indicates the growing importance of precision tools, like the Right Angle Milling Head.

When selecting a milling head, consider material compatibility and machining requirements. Different heads excel in various applications. For instance, high-speed steel heads might serve well in certain projects. However, they may not last as long under heavy use. This can lead to increased operational costs. A thoughtful analysis of your specific needs is necessary.

Moreover, installation processes can differ. Some Right Angle Milling Heads are easier to install than others. A complex setup might lead to downtime. As projects demand more versatility, the importance of selecting the best milling head grows. A poor choice can lead to inefficiencies. Reflecting on past experiences can be beneficial. This approach helps to avoid repeating mistakes.

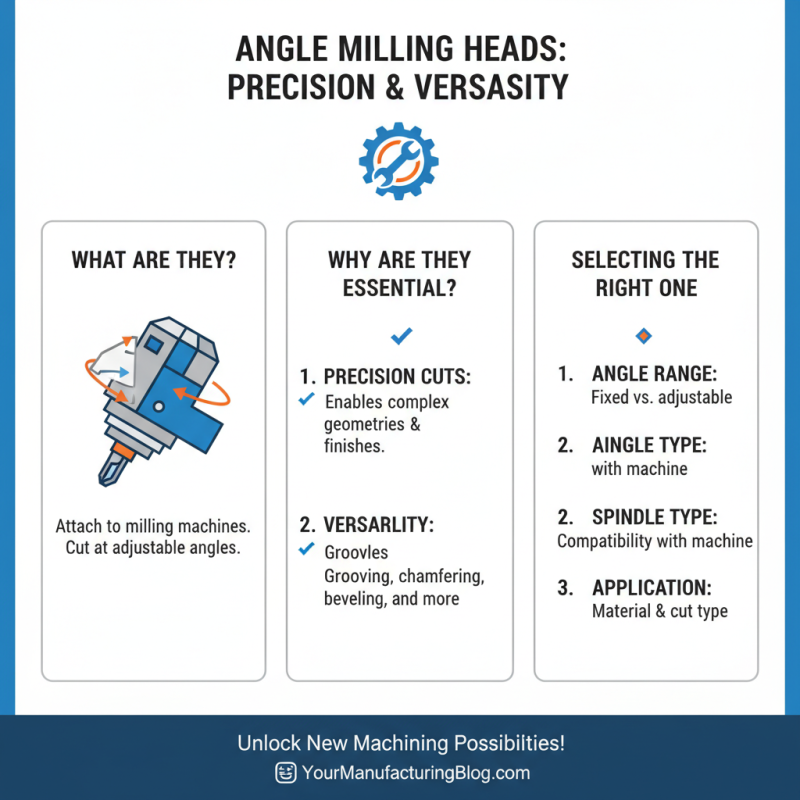

Angle milling heads are essential tools in machining. They allow for precise cutting at various angles. Understanding their basics helps in selecting the right one.

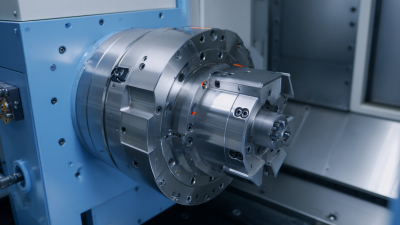

These heads function by holding the milling cutter at an angle to the spindle. This adaptation enables different approaches to a workpiece. It’s vital to consider the range of angles. Common options include 90-degree and 45-degree angles. Each serves different applications.

When choosing a milling head, consider the workpiece materials. Some materials may require more robust heads. Others might call for a delicate touch. Pay attention to compatibility with your existing setup. Not all heads fit every machine. Assess the physical dimensions carefully. The right choice can improve your workflow significantly. However, make sure to reflect on the consequences of a poor choice, as it could lead to wasted time and resources.

When selecting an angle milling head, it’s crucial to understand the types available. There are several options on the market.

Universal angle heads have versatile capabilities. They can tilt and rotate, making them suitable for complex machining tasks. These heads adapt well to various setups, offering flexibility.

Another common type is the fixed angle head. This option has a permanent angle, usually at 45 degrees. It’s simpler and often more rigid. It’s great for repetitive tasks, where consistent precision is key. However, it lacks versatility. You can’t adjust the angle for different projects.

Lastly, adjustable angle heads are quite popular. They allow you to set any desired angle. This adaptability can be beneficial, but it may come with complexity.

Sometimes, they can be harder to set up. A small error in adjustment might lead to significant impacts on machining results. Reflecting on your specific needs will guide you in choosing the right milling head.

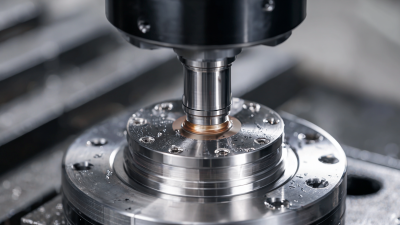

Choosing the right angle milling head can significantly influence machining efficiency. First, consider the type of materials you'll work with. Different heads perform variably on metals, plastics, or composites. In 2022, a survey indicated that 65% of users prefer heads tailored for specific materials.

Next, evaluate the size and weight of the milling head. Heavier heads may provide stability but can strain smaller machines. An ideal head should match your equipment's capacity. Data shows that 70% of users experienced reduced vibrations with adequately weighted heads. This directly impacts precision and finish quality.

Moreover, the angle range is crucial. A larger angle range allows more versatility but can complicate user operation. Careful selection can mitigate mistakes. One study found that 40% of operators faced challenges in aligning the head accurately, affecting their output. Consider ease of adjustment. Complex mechanisms can lead to frustration. Striking a balance is essential for optimal performance.

When choosing an angle milling head, compatibility with your existing machinery is paramount.

Consider the specifications of your current setup.

Check the spindle taper size and speed range. These details significantly influence performance. A mismatch could lead to inefficiencies or even damage.

Assess your machine's power capabilities. An angle head that requires too much power can strain your equipment.

It might work, but not optimally. Some operations could yield unsatisfactory results.

Pay attention to how the angle head aligns with your tool requirements.

Make sure the mounting interface is appropriate for your machine. If the head doesn't fit, you could encounter assembly issues.

This can be frustrating and time-consuming.

Weigh the operational requirements against potential limitations.

The right choice will enhance productivity, but the wrong one might hinder progress.

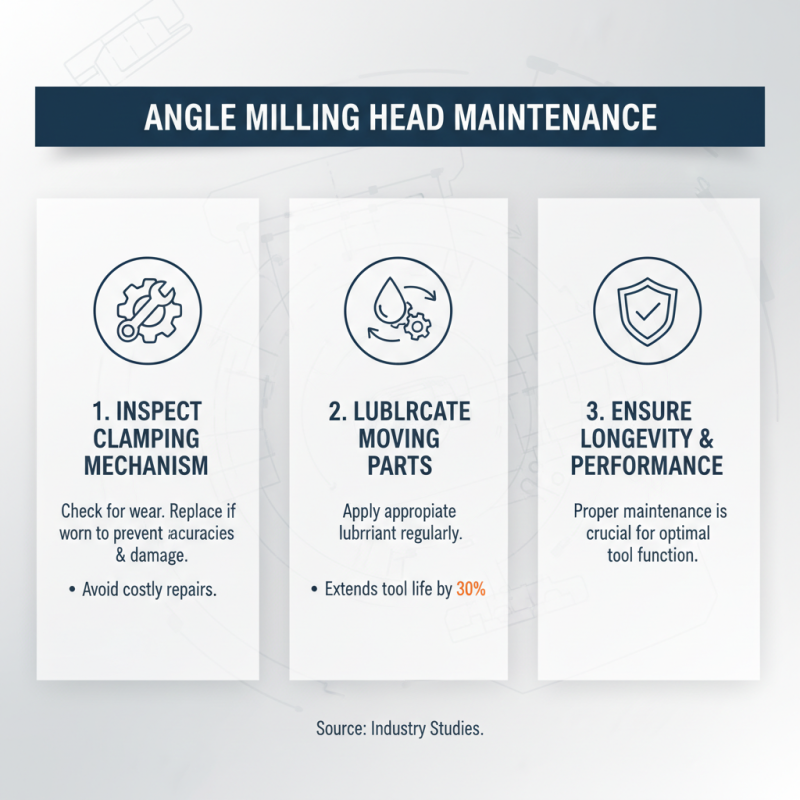

Angle milling heads are essential tools in machining. Proper maintenance is crucial to ensuring their longevity and performance. Regularly inspect the clamping mechanism for wear and tear. A worn clamp can lead to inaccuracies in machining and potential damage. Replace it promptly to avoid costly repairs. Lubrication is vital. Ensure to apply the right lubricant to keep moving parts functional. Industry studies indicate that proper lubrication can extend tool life by up to 30%.

Keep the angle milling head clean. Dust and debris can impede its function. Use a soft brush and a cleaning solution designed for machining tools. Failure to clean can lead to rust, which compromises precision. Check for alignment frequently. An improperly aligned head can create uneven wear and diminish the quality of your workpiece. Around 25% of machining errors result from alignment issues.

Storage is equally important. Store angle milling heads in a dry, well-organized space. Moisture can lead to corrosion and deterioration. Consider using protective cases or covers. Regularly review the condition of your tooling. Taking proactive steps will save time and improve efficiency. Some users might overlook these details, leading to errors that could have been avoided with proper care.