- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

When it comes to maximizing the efficiency and versatility of CNC machines, choosing the right Spindle Angle Head is critical. These specialized attachments allow for enhanced accessibility and greater precision in various machining tasks, making them an invaluable asset in modern manufacturing settings. The process of selecting the appropriate Spindle Angle Head can be challenging, given the multitude of options available on the market. Factors such as the machine's compatibility, the types of materials being machined, and the specific applications play vital roles in this decision-making process.

Understanding the key considerations and functionalities of Spindle Angle Heads will empower CNC operators and manufacturers to make informed choices that align with their operational needs. From straightforward adjustments to complex machining angles, the right angle head can significantly improve productivity by facilitating intricate designs and reducing cycle times. In this guide, we will explore essential insights and practical tips for selecting the optimal Spindle Angle Head tailored to your CNC machine, ensuring that your investment leads to increased performance and efficiency in your machining processes.

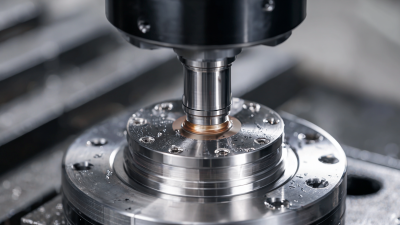

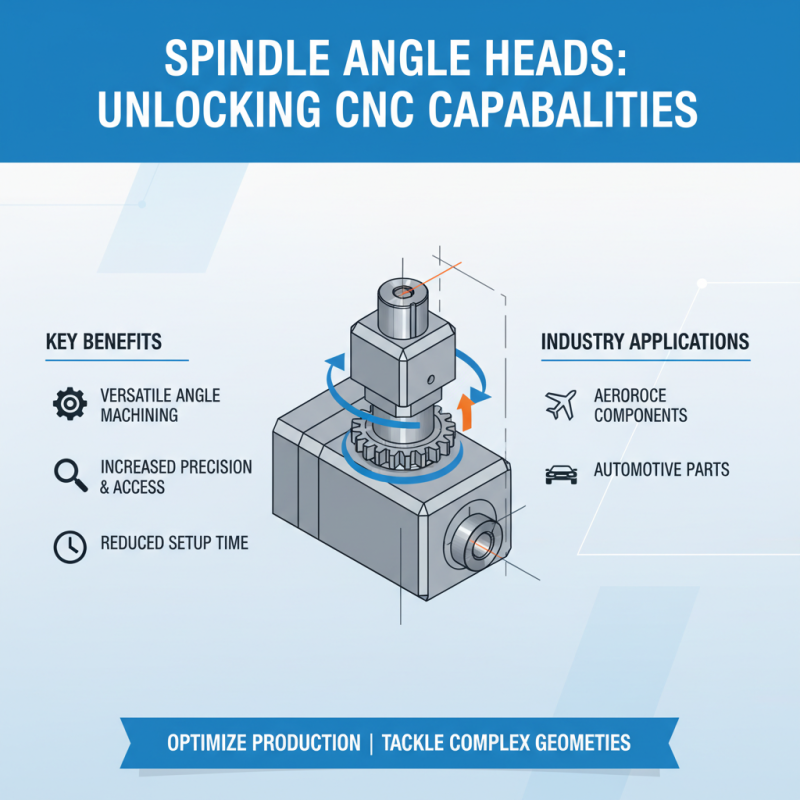

Spindle angle heads play a crucial role in enhancing the capabilities of CNC machines. These specialized attachments enable machining at various angles, providing distinct advantages in production settings. By allowing operators to access hard-to-reach areas and perform intricate machining operations without repositioning the workpiece, spindle angle heads improve efficiency and precision. This capability is particularly vital in industries where complex geometries are common, such as aerospace and automotive manufacturing.

Moreover, understanding the significance of spindle angle heads extends beyond mere mechanics; it involves recognizing their impact on overall machining strategy. Selecting the appropriate angle head can lead to substantial time savings and reduced tooling costs. With options available for different applications, such as 90-degree or even larger angle adjustments, manufacturers must consider factors like material type, desired finish, and operational speed. Careful evaluation of these elements ensures that the chosen angle head seamlessly integrates with the CNC machine’s setup, ultimately optimizing production workflows and enhancing productivity.

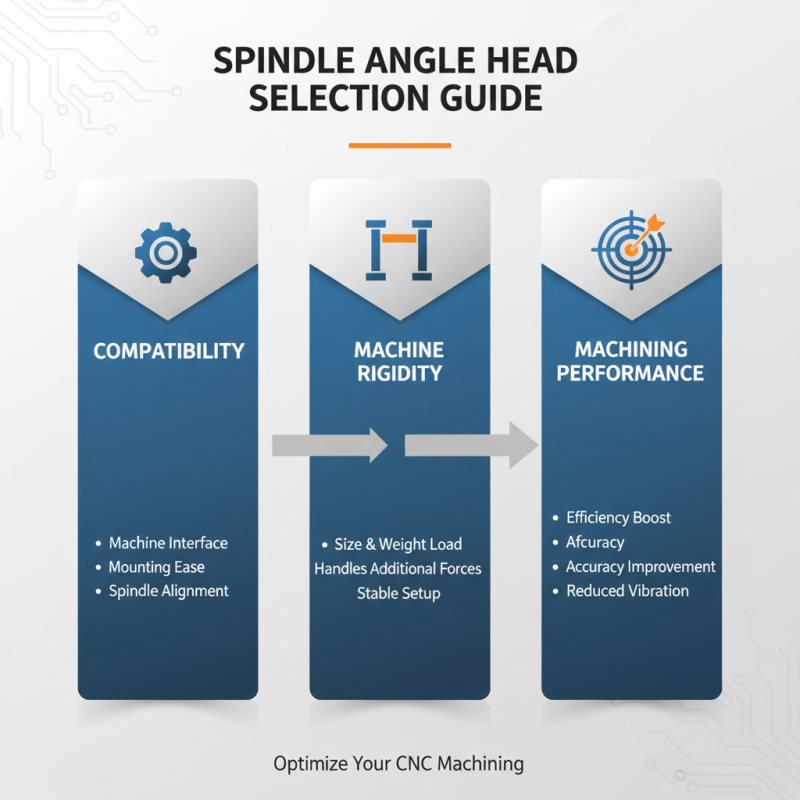

When selecting a spindle angle head for your CNC machine, there are several key factors to consider that can significantly impact your machining efficiency and accuracy. First and foremost, the compatibility of the angle head with your existing CNC machine is crucial. Ensure that the angle head can be easily mounted on your machine and that it aligns well with the spindle capabilities. It's also important to check the size and ability of the machine to handle the additional forces applied during machining processes, which includes evaluating the rigidity and stability of your setup.

Another vital consideration is the range of angles offered by the spindle angle head. Different applications may require various angles for optimal performance, so choose an angle head that provides the versatility your projects demand. Additionally, look into the material and build quality of the angle head itself; durable materials can withstand wear and tear, contributing to longer service life. Lastly, consider the maintenance and usability of the angle head—features such as easy tool changes and minimal maintenance requirements can lead to improved productivity and lower operational costs over time.

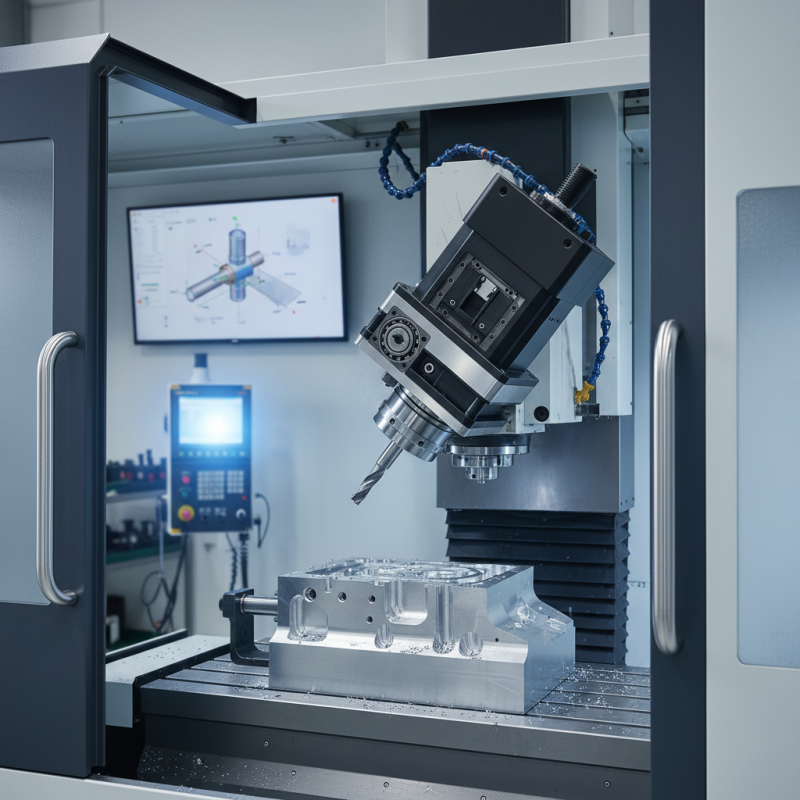

When selecting a spindle angle head for a CNC machine, understanding the various types available and their specific applications is crucial. Spindle angle heads generally fall into two main categories: fixed angle heads and adjustable angle heads. Fixed angle heads, typically designed for specific angles such as 45 or 90 degrees, offer high rigidity and precision, making them ideal for operations that require consistent, repeatable performance. According to a report by the International Machine Tool Builders Association, fixed angle heads can enhance productivity by up to 30% in certain machining scenarios, allowing for efficient multi-sided machining without the need to reposition workpieces.

On the other hand, adjustable angle heads provide flexibility, enabling users to set the spindle to various angles, which is particularly beneficial for complex geometries and intricate designs. These heads are commonly used in industries such as aerospace and automotive, where diverse machining processes are essential. A study from the Machining Journal highlights that adjustable angle heads can reduce setup times by up to 40%, facilitating quick transitions between different tasks while maintaining high accuracy levels. This adaptability not only enhances operational efficiency but also opens up new possibilities for innovative manufacturing processes.

When selecting a spindle angle head for your CNC machine, evaluating compatibility with your specific model is crucial for ensuring optimal performance. Different CNC machines have distinct mounting configurations, size constraints, and power capabilities that influence which angle head will function effectively. Begin by reviewing the technical specifications of both your CNC machine and the proposed spindle angle heads. Key factors include the tool holder type, taper size, and rotational speed compatibility. These specifications must align closely to prevent any issues during operation, which could impair productivity or lead to costly repairs.

Moreover, consider the intended applications for the spindle angle head. Certain models excel in high-torque applications while others may be more suitable for precision machining at high speeds. Assess the types of materials you plan to work with and the complexity of the projects you undertake. This understanding will guide you in selecting a spindle angle head that not only fits but enhances your machine's capabilities. Consulting the technical documentation and potentially seeking advice from professionals can further ensure that the choice you make aligns with your CNC machine's operational requirements and your overall production goals.

To ensure the longevity of your spindle angle head, regular maintenance is essential. A routine check-up should include cleaning the unit to remove dust and debris that can accumulate during operation. It's important to use appropriate cleaning solutions that won't damage any components. Additionally, lubricating moving parts with the manufacturer-recommended oil will help reduce friction and wear, enhancing performance and lifespan.

Monitoring the temperature during operation is another key factor in spindle maintenance. Excessive heat can lead to premature failure, so it's advisable to assess the cooling systems regularly. If your machine supports it, installing temperature sensors can provide real-time data, allowing you to detect overheating issues early. Moreover, conducting regular inspections of bearings and spindle connections can help identify wear or damage before they develop into more serious problems. Keeping an accurate log of maintenance activities can also assist in analyzing the spindle's performance over time, making preventive maintenance easier to manage.

| Aspect | Details | Maintenance Tips |

|---|---|---|

| Type of Angle Head | Fixed, Adjustable, or Swivel | Regularly inspect for proper alignment and locking mechanisms. |

| Material Compatibility | Aluminum, Steel, or Composite Materials | Clean the angle head after each use, keeping it free of debris. |

| Cutting Tool Selection | Tool Diameter and Length Considerations | Check tool wear and replace as necessary to avoid damage. |

| Cooling System | External vs Internal Cooling Methods | Ensure coolant channels are clear and free of blockages. |

| Spindle Speed | RPM Ranges Compatible with Angle Head | Monitor and adjust speed settings for optimal performance. |