- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right Heavy Duty Angle Head for your machining needs is crucial to enhancing precision and efficiency in your projects. As noted by David Jensen, a leading expert in precision machining, "Investing in a quality Heavy Duty Angle Head not only boosts productivity but also ensures the longevity of your machining tools." With the growing demand for high-performance machining solutions, understanding the various factors that contribute to the effectiveness of angle heads is essential.

The Heavy Duty Angle Head serves a vital role in expanding the capabilities of CNC machines, allowing for complex angled cuts and multi-sided machining without the need for frequent re-fixturing. As manufacturers strive to meet tighter tolerances and more intricate designs, selecting the appropriate angle head becomes imperative. From material selection to gear ratios, the choices you make can significantly affect the quality of your output and the overall operational efficiency.

In this guide, we will explore the key considerations for selecting the best Heavy Duty Angle Head tailored to your specific requirements. Whether you're a seasoned machinist or a newcomer to the field, understanding these elements will help you make an informed decision that aligns with your production goals. Let’s delve into the essential features and selection criteria that will elevate your machining capabilities.

Heavy duty angle heads play a crucial role in modern machining processes, enabling enhanced flexibility and precision in various applications. These specialized attachments allow for the adjustment of tool angles, making it possible to access hard-to-reach areas and perform complex operations without repositioning the workpiece. Industries such as aerospace, automotive, and mold-making particularly benefit from the use of heavy-duty angle heads, as they can dramatically reduce cycle times and improve overall productivity.

When selecting heavy duty angle heads, it’s important to consider their compatibility with your existing machinery and the materials you’re working with. Look for features such as rigidity, durability, and the ability to handle high torque loads. Additionally, pay attention to the weight and balance of the angle head, as this can impact operator comfort and the accuracy of your machining processes.

Tips for choosing the right angle head include assessing the specific machining tasks you routinely perform. Determine whether you require an angle head with adjustable angles for versatility or a fixed angle design for consistent operations. Moreover, consider the cooling system integration in your choice, as effective chip removal and coolant application are vital for maintaining tool performance and prolonging lifespan.

| Feature | Description | Applications | Max Torque (Nm) | Weight (kg) |

|---|---|---|---|---|

| Angle Range | 0 to 90 degrees | Milling and Drilling | 150 | 5.0 |

| Material | High-strength Steel | Heavy-duty Industries | 200 | 6.5 |

| Spindle Compatibility | ISO 30, ISO 40 | CNC Machines | 180 | 4.8 |

| Cooling System | Internal Cooling | Precision Machining | 220 | 7.2 |

| Gear Ratio | 1:4 | Tooling Operations | 160 | 5.5 |

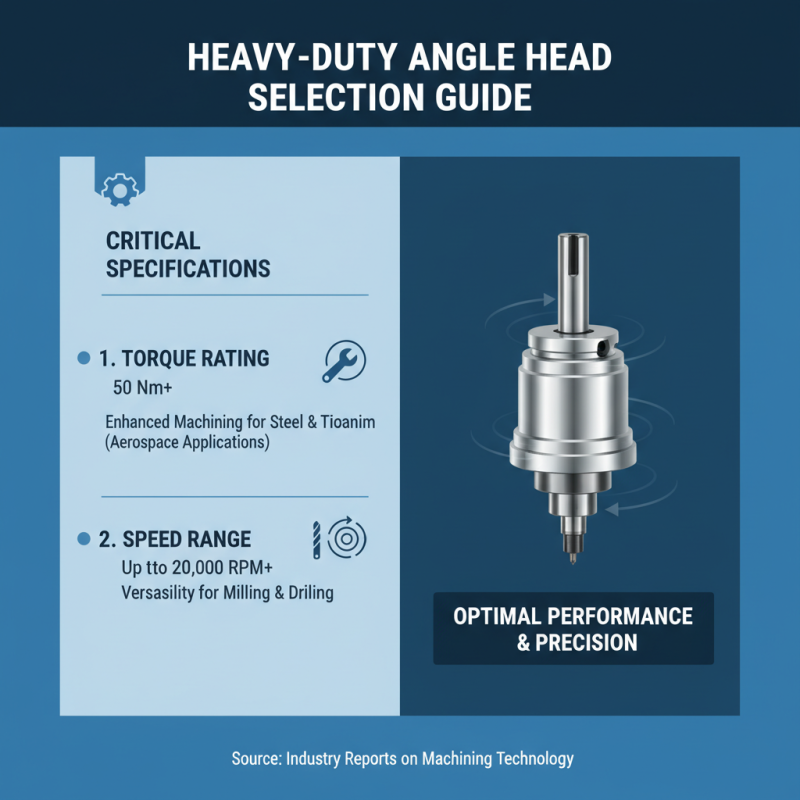

When selecting a heavy-duty angle head for your machining needs, several key specifications should be taken into account to ensure optimal performance and precision. One of the most critical factors is the angle head's torque rating. According to industry reports, angle heads with a torque rating of 50 Nm or above significantly enhance machining capabilities for materials such as steel and titanium, which are increasingly used in aerospace applications. Additionally, the optimal speed range of the angle head is crucial; units capable of operating effectively at high RPMs (reaching upwards of 20,000 RPM) provide the versatility required for various machining operations, from milling to drilling.

Another important specification to consider is the tool interface compatibility. Heavy-duty angle heads should support a wide range of tool types and sizes, ideally featuring a standard interface like ISO or BT for easy interchangeability. Reports indicate that angle heads with modular designs can facilitate quicker setup times and minimize downtime, increasing overall productivity by as much as 25%. Lastly, evaluating the materials and construction quality of the angle head is essential; units made from high-strength alloys or treated steels offer enhanced durability, with life spans extending beyond 3,000 hours in rigorous machining environments. By focusing on these specifications, manufacturers can select the best angle head that meets their operational demands effectively.

When selecting a heavy-duty angle head for machining applications, evaluating the material and build quality is paramount. The construction material directly influences both the performance and longevity of the tool. High-grade steel or specialized alloys are often preferred due to their strength and resistance to wear. Such materials ensure that the angle head can withstand the rigorous demands of machining while maintaining precision. Additionally, ensuring that components like gears and bearings are made from robust materials can enhance overall durability, preventing premature failure under heavy loads.

Furthermore, the build quality of the angle head affects its overall functionality and accuracy. Precision engineering and meticulous assembly are crucial in minimizing vibration and play during operation, which directly impacts machining tolerances. Attention to detail in the design, such as the alignment of the drive shaft and the quality of the seals, can prevent issues like coolant leakage and ensure a reliable connection to the machine tool. Ultimately, investing in a well-constructed angle head not only improves operational efficiency but also enhances the quality of the finished product in a demanding machining environment.

When selecting a heavy-duty angle head for machining needs, evaluating performance metrics such as speed, torque, and precision is vital. Speed, often measured in RPM (revolutions per minute), greatly influences productivity. According to industry reports, high-speed angle heads can operate at rates over 20,000 RPM, which can significantly reduce machining time, especially for operations requiring a high volume of parts. However, this speed must be balanced with the torque output; some high-speed models may sacrifice torque, resulting in potential inefficiencies in material removal.

Torque is the measure of the rotational force provided by the angle head, which is crucial for effective machining of tougher materials. For instance, angle heads capable of delivering over 30 Nm of torque are often recommended for heavy-duty applications. Many industry experts suggest that a reliable angle head should maintain consistent torque delivery throughout its operational range, ensuring optimal performance even under varying load conditions.

Tips: When choosing an angle head, assess the material you'll be machining and ensure that the torque specifications align with the material's hardness. Additionally, consider the cooling systems integrated into the angle head—effective cooling can maintain performance and prolong the tool's life. Lastly, if precision is your priority, look for angle heads that guarantee tight runout specifications, typically less than 0.01 mm, to ensure high-quality finishes in all your machining projects.

When selecting a heavy-duty angle head for machining applications, understanding industry standards and certifications is crucial. The International Organization for Standardization (ISO) has established benchmarks that ensure quality and compatibility in machining tools. For instance, ISO 9001 certification focuses on the effectiveness of quality management systems, which is essential for manufacturers producing reliable angle heads. According to a report from the American Society of Mechanical Engineers (ASME), over 70% of manufacturing defects are linked to the phase of design, emphasizing the need for thorough adherence to these standards during production.

Additionally, compliance with the American National Standards Institute (ANSI) ensures that angle heads meet specific performance criteria, including rigidity and precision. A recent industry analysis reported that up to 85% of manufacturing companies benefit from utilizing certified equipment, which directly impacts operational efficiency and product quality. Moreover, safety certifications, such as those from Underwriters Laboratories (UL), provide assurance that the tools meet rigorous safety guidelines, thereby mitigating risks associated with machining operations. Considering these standards not only enhances the credibility of the angle heads but also supports smoother machining processes and improved output quality, aligning with the evolving demands of the manufacturing sector.