- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

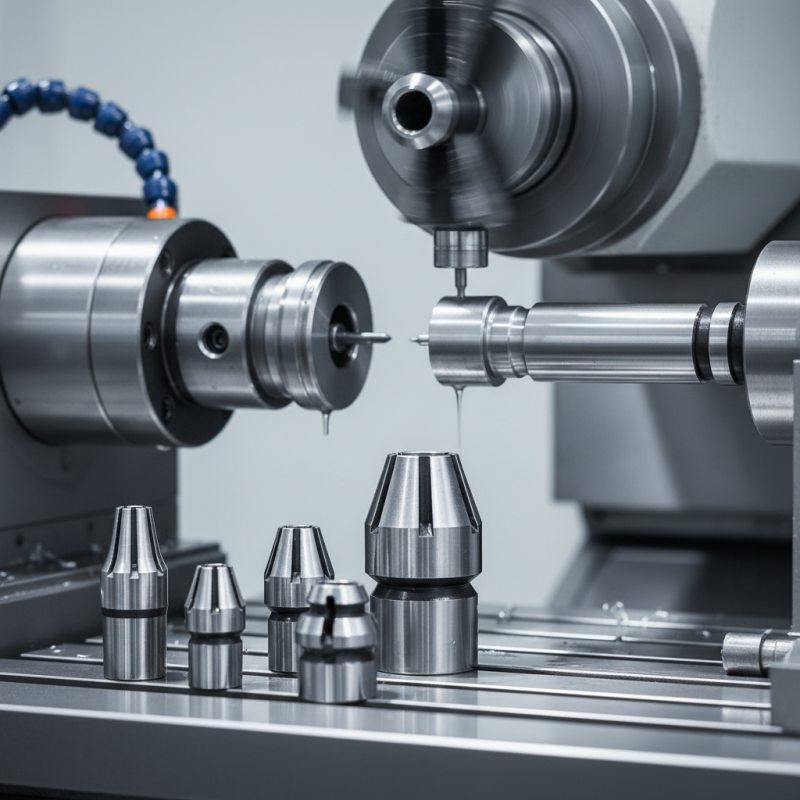

In the world of precision machining, Clamping Collets play a pivotal role. These tools ensure stability and accuracy during the machining process. They hold workpieces securely, preventing unwanted movement. This stability is crucial for achieving high-quality results.

The design of Clamping Collets allows for quick and efficient tool changes. This can lead to increased productivity on the shop floor. However, not all collets are created equal. Some may wear out faster than expected, affecting precision. Regular maintenance and inspection are necessary to avoid these pitfalls.

Moreover, choosing the right Clamping Collet for specific tasks requires thought. Factors such as size, material, and compatibility are vital. A mismatch can lead to errors. This highlights the importance of continuous learning in machining practices. Ultimately, understanding the significance of Clamping Collets elevates machining standards.

Clamping collets are crucial in the world of precision machining. They serve as a grip on tools and workpieces. This gripping ability ensures consistent accuracy during machining processes. The precision achieved depends heavily on the quality of collets. A loose grip can cause vibrations, which lead to errors. Operators often overlook this detail, but it is essential.

Collets are made from various materials. Each material has its own properties, affecting performance. For instance, some may provide better rigidity, while others excel in flexibility. Choosing the right collet for specific tasks is not always straightforward. Mistakes can lead to unwanted results, producing parts that do not meet specifications.

Proper maintenance of collets is equally important. Regular cleaning and inspection help avoid issues. Even small debris can obstruct the grip, causing problems. Machinists should be diligent in their upkeep. This attention to detail can make all the difference in achieving precision. An often ignored aspect, yet it plays a vital role in success.

In precision machining, tool stability is paramount. Clamping collets are crucial in achieving this stability. These devices hold cutting tools firmly in place, minimizing vibrations during machining. Inaccurate tool placement can lead to significant errors. Studies show that a mere 0.001-inch deviation can result in a 10% reduction in machining accuracy. This emphasizes the need for reliable collet systems.

Collets offer uniform clamping force. This ensures that the tool remains secure under varying pressure conditions. A stiff and stable setup can reduce tool wear. Reports have noted up to a 25% increase in tool lifespan with proper collet use. However, not all collets are created equal. Poorly designed collets can introduce unwanted play, negatively affecting precision. Regular inspections are essential to avoid these pitfalls.

Temperature fluctuations can impact collet performance. High temperatures may cause metal expansion, leading to slippage. This highlights the importance of considering material choices in collet design. Some manufacturers have found that using specialized alloys can enhance stability. Yet, this also raises costs. Balance between performance and budget is a consistent challenge in this industry.

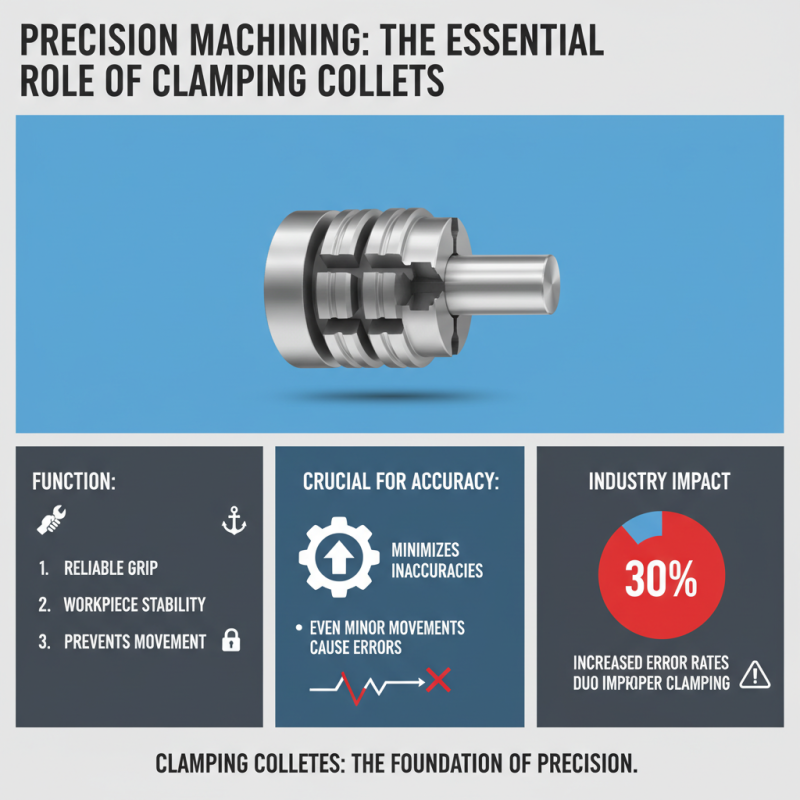

Clamping collets play a pivotal role in precision machining. They provide a reliable grip on the workpiece, ensuring that it remains stable during operation. This stability is crucial, as even minor movements can lead to inaccuracies. In fact, industry studies indicate that improper clamping can increase error rates by as much as 30%.

There are various types of clamping collets, each suited for different applications. The most common ones include wedge collets, which are renowned for their versatility, and even expansion collets, ideal for holding irregularly shaped workpieces. According to a report by the Precision Engineering Research Association, about 40% of manufacturers prefer wedge collets for their adaptability. Additionally, 25% utilize expansion collets for specialized tasks. Each type has its own strengths and limitations that need careful consideration.

While the effectiveness of clamping collets is evident, not all collets deliver optimal results. Variations in material quality can affect performance. Poorly made collets can lead to slips and reduce machining precision. According to a survey, nearly 15% of machinists reported experiencing issues due to low-quality collets in the past year. This highlights the need for thorough vetting when selecting collets for specific tasks.

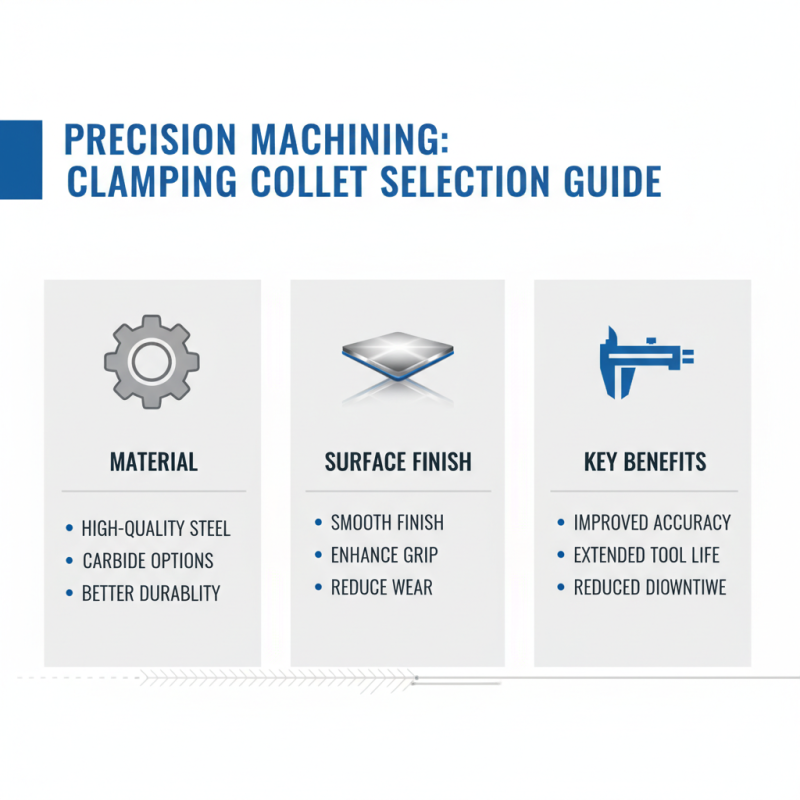

When selecting clamping collets for precision machining, several factors come into play. The material of the collet is critical. High-quality steel or carbide options tend to provide better durability. The surface finish also matters. A smooth finish can enhance grip and reduce wear.

Next, consider the size and type of the collet. Different machining tasks require specific collet sizes. A mismatched collet can lead to vibrations and inaccuracies. Additionally, the jaw design impacts the gripping force. Some designs allow for better clamping of odd shapes, which is useful in unique projects.

Lastly, don't overlook the cost. Higher quality often means a higher price. It’s essential to balance quality with budget constraints. However, investing in reliable collets usually pays off in the long run. Reflecting on these decisions can help avoid potential pitfalls and improve machining results.

Clamping collets play a vital role in precision machining. To maintain their effectiveness, regular care is essential. According to a report by the Precision Machining Association, approximately 30% of machine downtime is due to tool holder issues. Proper maintenance can significantly reduce this statistic.

To ensure optimal collet performance, regular cleaning is crucial. Debris and coolant residue can accumulate and affect precision. Collets should be inspected for wear and damage. A worn collet can lead to inaccuracies in machining. Utilizing the wrong collet can increase the chance of workpiece defects.

Lubrication is also key. Insufficient lubrication can cause friction and wear. The appropriate lubricant helps reduce the risk of seizing. Operators should be trained to handle collets with care. A careless approach can damage delicate components. Keeping an organized workspace can help prevent these issues. In summary, understanding the nuances of maintenance impacts overall machining success.