- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today’s competitive manufacturing landscape, precision is paramount. The demand for high-quality components is ever-increasing. A CNC machine collet is a critical component in achieving this precision. According to recent industry reports, CNC machining accounts for over 60% of modern manufacturing processes. This highlights the importance of effective tool holding systems.

A CNC machine collet ensures that tools remain securely in place during operation. This stability minimizes vibrations and enhances accuracy. Mishaps caused by improper tool holding can lead to costly errors. A study by the American Manufacturing Association noted that nearly 30% of machining errors stem from tool slippage. This statistic underlines the need for reliable collet systems.

However, not all collets are created equal. Variation in quality can lead to significant performance differences. Investing in high-quality CNC machine collets can improve overall machining efficiency. It is essential for manufacturers to reflect on their current tool holding systems. Upgrading to superior collet technology could address precision gaps in their processes.

CNC machining plays a crucial role in modern manufacturing. It employs computer-controlled tools to create precise components. This process enhances efficiency and reduces human error. Manufacturers rely on CNC machines for complex shapes and tight tolerances. The accuracy achieved is unparalleled, making it essential in industries like aerospace and automotive.

Collets are vital components of CNC machines. They securely hold cutting tools in place during operation. A well-functioning collet ensures stability and precision. If the collet fails, it can lead to poor quality and costly rework. Understanding the importance of this small part is often overlooked. Many manufacturers underestimate the impact of a faulty collet.

In CNC machining, even minor mistakes can lead to significant issues. Poor collet performance might cause vibrations. These vibrations can result in inaccurate cuts. Therefore, regular maintenance of the collet is essential. Reflecting on the collet's role can improve overall machining effectiveness. Every detail matters in achieving the desired outcome.

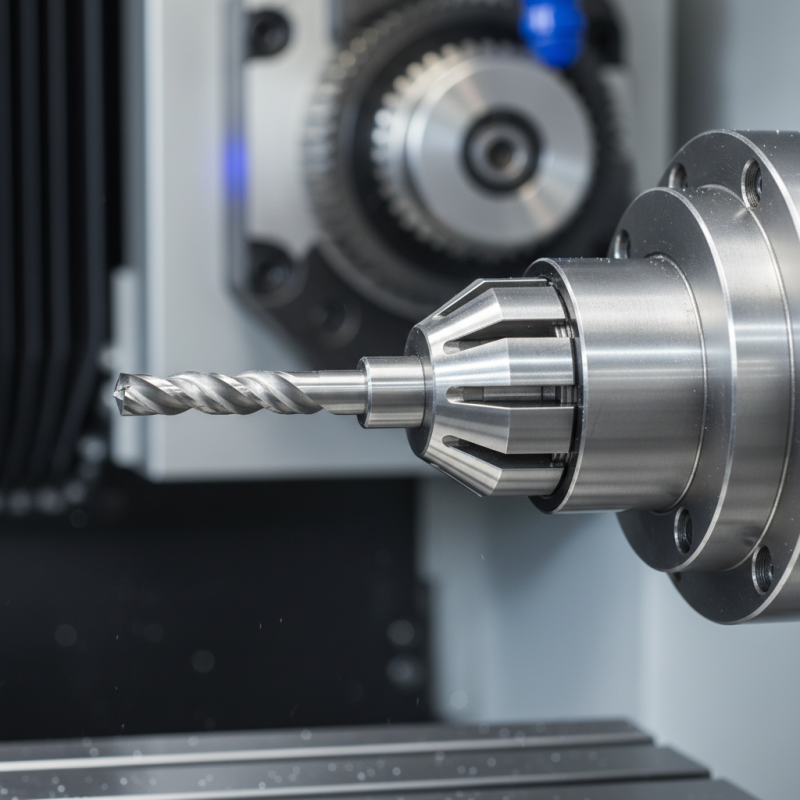

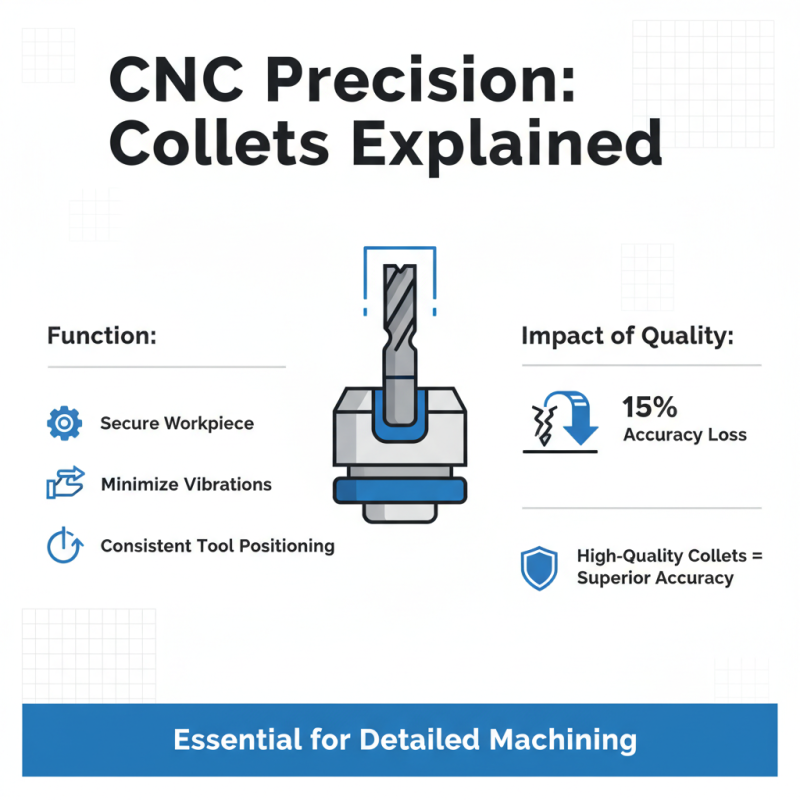

CNC machine collets are vital for achieving precision in machining processes. These essential tools hold the workpiece securely during milling or drilling. A study revealed that improper clamping can lead to a 15% reduction in machining accuracy. This highlights the importance of using high-quality collets. They minimize vibrations and maintain consistent tool positioning, essential for detailed work.

Collets come in various sizes and designs, tailored for specific tasks. A report by the International Journal of Advanced Manufacturing Technology indicated that the right collet can increase machining efficiency by over 20%. However, many operators overlook the impact of collet choice. Sometimes, operators use generic collets, leading to less-than-ideal results. Not all collets fit the same. This creates potential issues during operation.

Another factor to consider is wear and tear. Collets may degrade over time and affect precision. Regular inspection is crucial, yet often neglected. Many shops fail to address this, risking costly errors. In precision machining, small mistakes can cascade into larger defects. This underlines the necessity for a reliable collet that maintains grip and precision throughout its lifespan. Making informed choices around collet use can lead to superior performance in CNC machining.

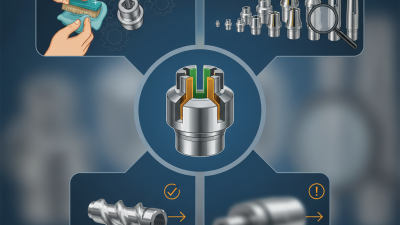

CNC collets are vital in precision machining. They come in various types, each suited to specific applications. The most common types include ER collets, which are versatile and widely used for holding tools. There are also 5C collets, ideal for workpieces that require tight grip and accuracy.

Another type is the collet chuck. It provides a secure hold while minimizing vibration. This is crucial for achieving high precision in milling and turning operations. The design of each collet type influences its effectiveness for different machining tasks. So, understanding their specific applications is essential.

**Tip:** Always match the collet type to your CNC machine's needs. Check for compatibility and specifications. It can save you time and enhance work quality.

Remember, not all collets are created equal. Occasionally, a collet may not grip as expected, leading to imprecise cuts. Regular maintenance is essential for optimal performance. Inspect for wear and damage frequently. This attention to detail can prevent costly mistakes.

The performance of a CNC machine collet plays a crucial role in achieving precision outcomes. Factors such as material type, design, and geometry must be considered carefully. A quality collet, made from durable materials, ensures better grip and stability during machining. However, there's always room for improvement. Even the best collets can wear out, leading to reduced accuracy over time.

Another factor is the collet's size and fit. A snug fit is essential for precision. If the collet is too loose, tool slippage can occur. This often happens due to wear or improper handling. Adjusting to the right size can solve some issues, yet it might not be perfect. Users sometimes rely too much on a single collet design, overlooking alternatives that may provide better performance.

Lastly, the machining conditions also affect collet efficiency. High-speed operations generate heat, which can lead to deformation. Additionally, the choice of coolant can impact collet lifespan. Regular maintenance is often neglected, yet it is vital. Users should keep an eye on wear patterns and be open to switching out collets more frequently. Finding the perfect balance is an ongoing journey for precision machining.

CNC collets play a critical role in achieving precision in machining processes. They are responsible for holding tools securely, which directly affects manufacturing accuracy. Proper maintenance can enhance their lifespan significantly. Data shows that well-maintained collets can last up to 50% longer than those neglected. Regular cleaning is crucial. Dust and debris can cause gripping issues, leading to vibrations during operation. These vibrations can compromise precision, resulting in costly errors.

Checking for wear is another essential step. Frayed edges or cracks can lead to inconsistent tool performance. It's advisable to inspect collets frequently, as even small imperfections can influence outcomes. Lubrication also matters, albeit in moderation. Too much oil can attract dirt, while too little can cause unnecessary friction. Understanding these nuances is vital for maintaining tool accuracy.

Moreover, the environment influences collet longevity. Humidity and temperature fluctuations can deteriorate material integrity over time. Storing collets in a stable environment reduces this risk. It's a simple step but often overlooked. Regular training for operators on collet care can yield better precision. Emphasizing these maintenance practices ensures efficiency and longevity. Proper care of CNC collets is not just beneficial; it’s essential for maintaining high-quality precision machining.

| Dimension | Material | Usage | Maintenance Tips | Expected Lifespan |

|---|---|---|---|---|

| 1/8 inch | Steel | Engraving | Clean with non-abrasive cloth | 5 years |

| 1/4 inch | Aluminum | Milling | Inspect for wear regularly | 3 years |

| 3/8 inch | Carbide | Drilling | Lubricate threads | 8 years |

| 1/2 inch | Bakelite | Routing | Store in a dry place | 4 years |