- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

The precision machining industry has continually evolved, driven by advancements in technology and the increasing demand for higher accuracy and efficiency. Central to this evolution is the CNC mill boring head, a critical component that enhances the drilling and boring capabilities of CNC milling machines. According to a report from MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2026, with a significant portion fueled by the need for precision components across various sectors, including aerospace, automotive, and healthcare. The competence of CNC mill boring heads in achieving tight tolerances and smoother surface finishes plays a vital role in meeting this demand.

As manufacturers strive for operational excellence, the optimization of machining processes becomes imperative. The utilization of CNC mill boring heads not only improves machining accuracy but also allows for the reduction of cycle times and production costs. A study by Grand View Research indicates that the growing trend toward automation and computer numerical control in manufacturing is reshaping the landscape, pushing the boundaries of efficiency and precision. With the right knowledge and techniques, machinists can maximize the potential of CNC mill boring heads, ensuring that they remain at the forefront of precision engineering and contribute to the competitive edge of their operations.

CNC mill boring heads play a pivotal role in precision machining by enabling accurate boring operations in a variety of materials. Understanding the different types of boring heads is essential for machinists looking to optimize their processes. The two main categories are fixed boring heads and adjustable boring heads. Fixed boring heads are designed for specific bore diameters and are generally simpler in construction, providing stability and precision for repetitive tasks. Conversely, adjustable boring heads offer versatility, allowing operators to fine-tune the diameter of the bore, making them ideal for projects that require varied specifications.

In addition to the types, the functionality of CNC mill boring heads can be further categorized based on their design features. Some boring heads incorporate interchangeable tooling, enabling quick changes between different cutting tools, which enhances productivity and reduces downtime. Others may feature built-in coolant systems that improve chip removal and prolong tool life. Understanding these functions helps machinists select the appropriate boring head for their specific applications, ensuring superior performance and accuracy in their machining tasks. By mastering the features and types of CNC mill boring heads, professionals can significantly elevate the quality of their work and streamline their machining operations.

| Type of Boring Head | Function | Key Features | Ideal Application |

|---|---|---|---|

| Adjustable Boring Head | Allows fine adjustments to bore diameter. | Precision adjustment mechanism, easy to handle. | General machining, custom diameters. |

| Finishing Boring Head | Used for achieving a high-quality surface finish. | Ultra-fine adjustments, rigid construction. | Precision components, tight tolerances. |

| Tapered Boring Head | Holes with a tapered finish, usually for fasteners. | Specialized taper angle design. | Mounting holes for fittings and fasteners. |

| Indexable Boring Head | Uses indexable inserts for cutting. | Cost-effective, easily replaceable inserts. | Heavy-duty machining, high production runs. |

| Digital Boring Head | Provides digital readout for precision settings. | LCD display, user-friendly interface. | Complex machining tasks requiring high accuracy. |

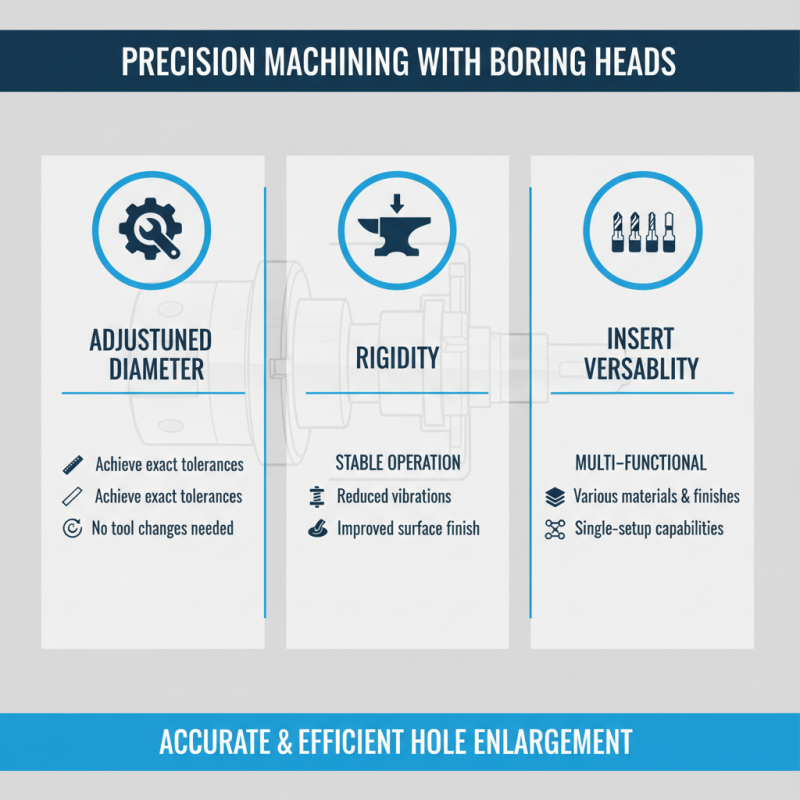

Boring heads are essential tools in precision machining, allowing for accurate and efficient hole enlargement in various materials. Key features of precision machining with boring heads include adjustability, rigidity, and insert versatility. The ability to adjust the diameter of the cut is crucial, as it enables machinists to achieve the desired tolerances without having to switch to different tools. Rigidity ensures stability during operation, which contributes to the overall precision of the machining process. Furthermore, using interchangeable inserts broadens the capabilities of boring heads, allowing for the achievement of various finishes and sizes in a single setup.

For optimal performance when using boring heads, there are several tips to consider. Firstly, ensure that the boring head is properly aligned and secured in the machine to minimize any play that could affect precision. Secondly, selecting the appropriate cutting speed and feed rate is vital; too fast can cause excessive wear or damage, while too slow can reduce efficiency. Lastly, regularly inspect and maintain the boring heads and inserts to ensure they remain sharp and functioning correctly, as this directly impacts the quality of the machined parts.

By focusing on these essential features and tips, machinists can harness the full potential of boring heads, leading to enhanced accuracy and efficiency in their precision machining projects. Proper technique and maintenance are critical in achieving the best results and prolonging the life of the tooling.

When selecting the right boring head for CNC milling, understanding the specific requirements of your machining project is crucial. Boring heads come in various types and sizes, tailored for different applications. A recent industry report indicated that improper selection of boring tools can increase cycle time by up to 30%, underscoring the importance of making informed choices. Begin by assessing the diameter range and depth of cut required for your project; this will guide you toward a suitable head that can achieve the required precision and finish.

Another key factor is the material you are machining. Different materials, such as aluminum, stainless steel, or titanium, demand varying chip removal rates and tolerances. According to data from the Metalworking Industry Report, using the correct boring head can improve tooling life by 40% when matched properly to the material being cut. Pay attention to the tool geometry as well, as this can significantly influence cutting forces and vibration. By considering these elements, you can enhance productivity and achieve the desired machining accuracy, making your CNC projects more efficient overall.

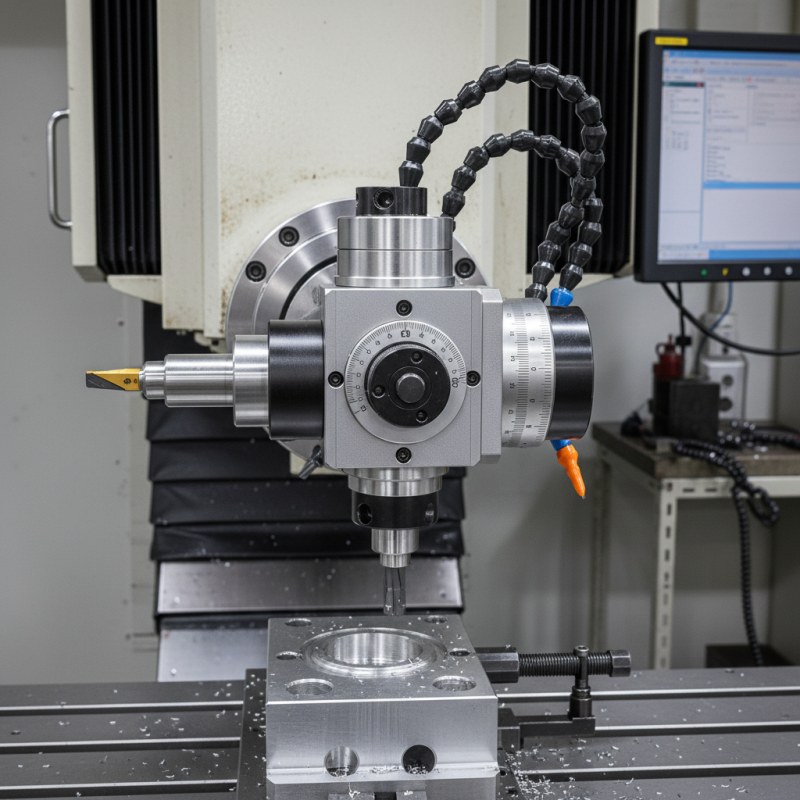

When setting up a CNC mill boring head, precision and accuracy are of utmost importance. Begin by ensuring that the boring head is securely mounted on the machine spindle. Use appropriate tools to tighten the connection, preventing any movement during operation that could lead to inaccurate cuts. It is essential to align the boring head carefully in relation to the workpiece; slight misalignment can significantly affect the final dimensions. Utilize measuring tools like calipers or dial indicators to verify the alignment before commencing any machining processes.

Once the boring head is securely set up, it’s crucial to choose the right cutting speed and feed rate. The material being machined dictates these parameters; for harder materials, slower speeds and feeds are generally required to avoid tool wear, while softer materials may allow for higher speeds. Additionally, making sure the cutting tools are sharp and in good condition is key to achieving a high-quality finish. Monitoring the cooling and lubrication during the machining process can also enhance tool life and improve the overall quality of the boring operation. By following these best practices, machinists can maximize the effectiveness and precision of their CNC mill boring operations.

Achieving optimal boring performance with CNC mill boring heads requires awareness of common pitfalls that can undermine precision machining. One frequent mistake is failing to select the appropriate cutting speed and feed rate for the material being processed. Each material has its specific characteristics that demand tailored parameters. Ignoring these can lead to excessive tool wear, poor surface finish, and ultimately compromised dimensional accuracy of the finished part. Operators should always consult recommended guidelines based on the material to ensure efficient cutting conditions.

Another common error is improper tool setup and alignment. If the boring head is not correctly secured or misaligned, it can lead to inaccuracies in the bore diameter and surface quality. Additionally, using dull or improperly sharpened cutting tools can significantly affect performance, resulting in chatter and uneven cutting. Operators should regularly inspect and maintain their tools, ensuring they are sharp and aligned correctly before operation. By paying attention to these factors, machinists can enhance their boring capabilities, achieving the precision necessary for high-quality outcomes.