- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

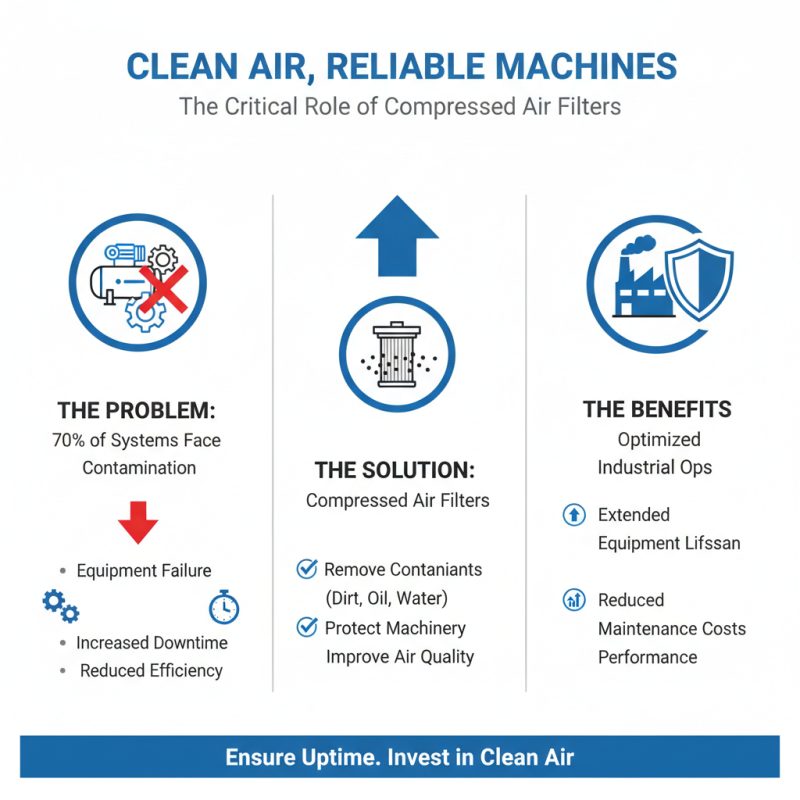

Compressed air systems are vital in many industrial settings, powering tools and machinery. However, the quality of compressed air is crucial. Contaminants can harm equipment, increase maintenance costs, and lead to production downtime. Reports estimate that over 70% of industrial air systems suffer from contamination issues. This makes the role of compressed air filters indispensable.

A compressed air filter removes harmful particles and moisture from the air supply. Neglecting this can lead to significant damage and costs. For instance, a single particle can trigger equipment failure. Research shows that using high-quality filters can extend the lifespan of machinery by at least 30%. Many industries still overlook this essential aspect, leading to inefficiencies.

Investing in compressed air filters may seem minor, yet it's impactful. Many operations experience hidden costs from poor air quality. This reflects a need for better awareness and action in the industry. Proper filtration can transform a facility's performance and reduce long-term expenses.

Compressed air plays a vital role in many industrial applications. It drives tools, acts as a conveyor medium, and powers various machinery. The efficiency of these systems hinges on the quality of compressed air. Contaminated air can lead to significant issues, including equipment damage and production downtime.

Many industries rely on clean, dry air for optimal performance. For instance, in food processing, air contamination can compromise product safety. Similarly, automotive manufacturing requires pure air to ensure precision in operations. The presence of oil, moisture, or dust in compressed air can create serious challenges. These contaminants can damage sensitive equipment, leading to costly repairs.

Yet, not everyone acknowledges the importance of proper filtration. Some companies overlook routine maintenance of their air filters. This negligence can result in poor air quality, affecting overall productivity. Regular checks and replacements are critical. Without them, the risks of inefficiency grow. Contaminants can silently wreak havoc, making awareness of filter importance essential in any industrial setting.

Compressed air filters play a vital role in industrial applications. These filters remove contaminants from compressed air, ensuring its quality. Particles like dust, oil, and moisture can damage equipment. The filtration process helps maintain cleaner air for various operations.

When air moves through a compressed air system, it carries harmful substances. Filters trap these impurities effectively. This keeps machines running efficiently and reduces wear and tear. A well-maintained filter can improve production quality. However, some industries may overlook filter maintenance. Regular checks and replacements are crucial for optimal performance.

Ignoring filter functionality can lead to issues. Contaminated air can cause equipment failures and increased costs. In some cases, businesses may experience downtime, affecting productivity. It's essential to recognize the importance of these filters. When proper filtration is in place, operations run smoother. Investing in good quality filters pays off in the long run.

In industrial settings, compressed air filters play a vital role. They ensure the air used in production processes is clean and free from contaminants. Various types of filters are employed to meet specific needs.

Particulate filters eliminate dust and dirt from the air supply. They protect equipment and improve efficiency.

Coalescing filters are another essential type. They remove moisture and oil from compressed air. This prevents corrosion and equipment failure. Adsorption filters are used for eliminating odors and vaporized contaminants. They play a crucial role in industries where air quality is paramount.

Understanding different filter types helps businesses choose the right solutions. It's not always straightforward. Some companies may underestimate how crucial these filters are.

Maintenance routines can also be lacking. Without regular checks, filters can become less effective. This can lead to costly downtime. Careful consideration in filter selection is key to maintaining operational integrity.

Compressed air filters play a crucial role in industrial applications. They remove contaminants from the air, ensuring that machinery operates efficiently. According to a recent industry report, nearly 70% of all compressed air systems experience contamination issues. This can lead to equipment failure and increased downtime.

Maintenance of these filters is often neglected. Regular checks can prevent significant problems. Many facilities overlook the recommended replacement intervals. A report found that 30% of users change filters less frequently than advised. This can negatively impact air quality and machine performance. Replacing filters at the correct time enhances system reliability.

The costs associated with dirty filters are high. Poor filtration can lead to energy losses, raising operational costs by up to 30%. Awareness of proper maintenance practices can save money. Filters should be inspected monthly. Operators must be vigilant. A simple maintenance routine can prevent catastrophic failures and ensure efficiency in industrial settings.

Compressed air filters play a critical role in ensuring the efficiency and safety of industrial processes. A study by the Compressed Air and Gas Institute revealed that up to 70% of compressed air systems have contamination issues. This can lead to substantial equipment wear and unexpected failures. Contaminants like water, dust, and oil can harm sensitive machinery and compromise product quality.

The quality of filters directly impacts equipment performance. A high-efficiency filter can remove 99.9% of particles, thus extending the life of tools and reducing maintenance costs. According to industry reports, poor filter selection can result in energy losses, leading to a potential increase of 30% in operational costs. Such inefficiencies affect both profitability and environmental sustainability.

Moreover, safety is a pressing concern. Contaminated air can cause serious accidents, where machinery malfunctions pose risks to workers. One report indicated that nearly 25% of workplace accidents stem from equipment failure linked to inadequate filtration. Regular assessment of filter quality is essential. It’s a small step that can have profound implications for safety and productivity.