- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Choosing the right CNC machine collet is crucial for the success of your machining projects, especially as technology advances and the needs of industries evolve. As we approach 2025, understanding the diverse types of collets available and their specific applications will empower machinists and manufacturers to achieve optimal performance and precision. A well-matched collet not only enhances tool stability and accuracy but also contributes to the efficiency and safety of CNC operations.

In this guide, we will explore the various digital types of CNC machine collets, examining their features, benefits, and suitable applications. From traditional designs to innovative advancements that leverage modern technology, selecting the appropriate collet can make a significant difference in the quality of your work. Whether you're a seasoned professional or a novice, mastering the intricacies of CNC machine collet options will enable you to make informed decisions that elevate your projects in an increasingly competitive landscape. As we delve into this topic, you'll discover essential insights that will help you navigate the choices available to you in the evolving world of CNC machining.

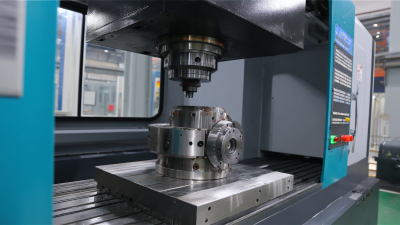

When selecting a CNC machine collet, understanding the different types and their applications is crucial for optimizing machining efficiency. Collets are designed to hold tools securely and can vary significantly in type. The most common types include ER collets, which are popular for their versatility and ability to accommodate various tool diameters. According to a report by Grand View Research, the global CNC machine tool market is expected to reach $100 billion by 2025, highlighting the importance of choosing the right collet for maintaining precision and productivity.

Another vital type is the TG collet, which offers a lower profile and is ideal for high-speed applications, providing excellent balance and reducing runout. As noted by Research and Markets, the demand for high-performance tooling solutions in CNC machining is driving innovations in collet design, enabling manufacturers to achieve tighter tolerances and improved surface finishes.

Understanding these types ensures that manufacturers can select collets that align best with their specific machining requirements, thus enhancing operational efficiency and product quality.

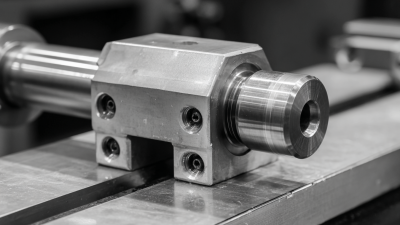

When selecting the right CNC machine collet for your projects, several key factors must be considered to ensure optimal performance and precision. First, the size and type of the collet should match the tools and workpieces you plan to use. Collets come in various sizes, and choosing one that aligns with the diameter of your tools will facilitate better grip and accuracy. Additionally, you'll want to consider the collet's engagement style—whether it is a precision collet for tighter tolerances or a standard collet for general purposes.

Another crucial factor is the material from which the collet is made. Different materials offer varying levels of strength, durability, and thermal resistance. For instance, steel collets are robust and standard for many applications, whereas harder materials like carbide may be preferred for high-precision work. Furthermore, examining the collet's design features, such as rubber cushioning to absorb vibrations or specialized clamping mechanisms, can also enhance your machining results. By carefully evaluating these factors, you can select a CNC collet that best fits your project requirements, ensuring smoother operations and better end results.

When selecting the right CNC machine collet for your projects in 2025, it's essential to understand the strengths and weaknesses of the leading collet brands. A comparative analysis reveals that brands such as ER, V-Flange, and collet chuck systems offer unique features tailored to various machining needs. The ER collet, known for its versatility and wide range of available sizes, can accommodate different tool diameters while providing excellent grip. This flexibility makes it a preferred option for diverse applications, from woodworking to metalworking.

On the other hand, V-Flange collets are specifically designed for high-precision tasks, ensuring minimal runout, which is crucial for achieving tight tolerances. They are often favored in industries where precision is paramount, such as aerospace and automotive manufacturing. Additionally, some brands incorporate advanced materials and coatings that enhance durability and reduce wear, which can significantly impact long-term performance. By weighing these factors, CNC users can make an informed decision that aligns with their project's demands and budget in 2025.

| Collet Type | Material | Price Range | Accuracy (mm) | Common Uses |

|---|---|---|---|---|

| ER Collet | Steel | $20 - $50 | 0.01 | Milling, Drilling |

| TG Collet | Aluminum | $30 - $70 | 0.005 | Precision Machining |

| W Collet | Carbon Steel | $15 - $40 | 0.02 | General Purpose |

| C Collet | Bakelite | $25 - $60 | 0.015 | Routing |

| S Collet | Titanium | $35 - $80 | 0.008 | High-Speed Machining |

When selecting a CNC machine collet, aligning the collet size with the specific requirements of your project is crucial for achieving optimal performance and precision. The first step is to evaluate the diameter of the tools you intend to use. Collets come in various sizes, and selecting the right one ensures a snug fit, which minimizes tool vibration and enhances accuracy during machining operations. For instance, if your project utilizes a router bit with a diameter of 1/4 inch, you must choose a collet specifically designed to accommodate that size to prevent slippage and maintain cutting precision.

In addition to the tool diameter, consider the type of material you will be machining. Different materials can require varying degrees of clamping force and stability, which can be influenced by the collet design. For softer materials like plastic, a standard collet may suffice, while hard metals might benefit from a more rigid collet type, potentially equipped with additional features like lock-nuts for enhanced grip. Understanding these project-specific requirements will guide you in making an informed decision, ensuring both the efficiency of your CNC setup and the quality of your final product.

Maintaining CNC collets is essential for ensuring precision and efficiency in machining projects. According to a recent report from the American Society of Mechanical Engineers, nearly 30% of machining downtime is attributed to tool wear and maintenance issues. To prolong the life of your CNC collets, regular inspection and cleaning should be a priority. Removing debris and coolant residues can greatly reduce wear and prevent misalignment during machining operations.

Additionally, proper storage plays a vital role in collet longevity. A study published by Machining World Magazine highlights that collets stored in controlled environments exhibit 20% less wear over a five-year period compared to those stored improperly. Utilizing protective covers and dedicated storage solutions will help mitigate corrosion and mechanical damage, ensuring that your CNC collets remain in optimal condition for as long as possible. Implementing these maintenance tips can lead to enhanced performance and increased productivity in your machining projects.