- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

As the global demand for clean water continues to rise, the oil and gas industry faces increasing scrutiny over its environmental impact. According to a report by MarketsandMarkets, the oil-water separation market is projected to reach USD 21.6 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth trajectory underscores the vital role that technologies like the Industrial Oil Water Separator play in addressing the pressing need for effective wastewater treatment solutions. With stricter regulations on water quality and an ever-increasing focus on sustainability, innovations in oil water separation technology are not just beneficial—they are necessary for compliance and corporate responsibility.

In 2025, the landscape of oil-water separation will likely be transformed by advancements in materials science and biotechnological methods, enabling more efficient and cost-effective solutions for global buyers. Cutting-edge developments such as membrane filtration and electrocoagulation are expected to enhance the performance of Industrial Oil Water Separators, making them more adaptable to a variety of industrial applications. With the growing emphasis on resource recovery and circular economy principles, the future innovations in this sector not only promise to improve environmental outcomes but also present lucrative opportunities for businesses worldwide to optimize their operations and contribute to a sustainable future.

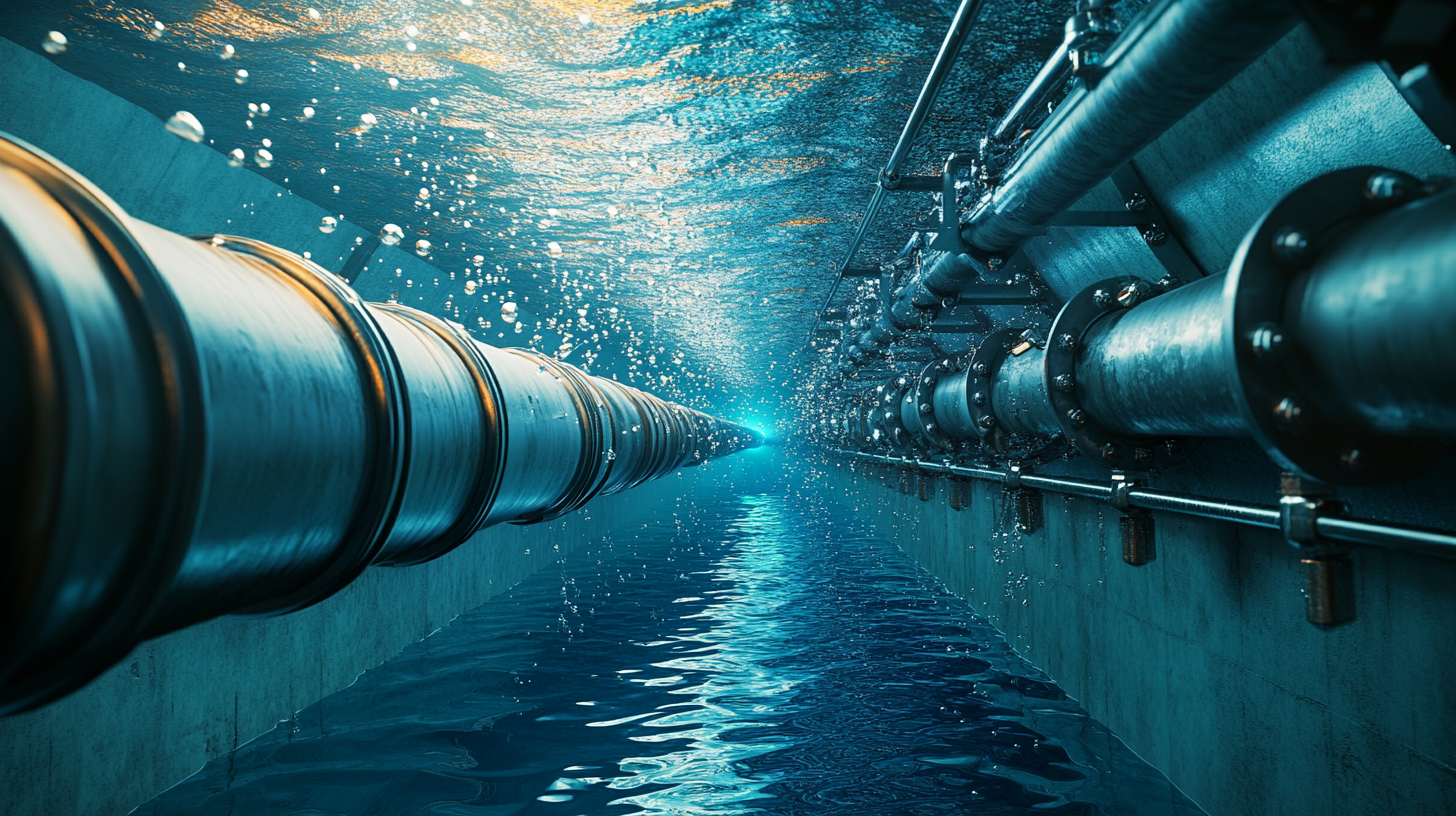

Emerging technologies in oil water separation are set to transform the efficiency and effectiveness of separation processes by 2025. As the demand for oil and gas continues to escalate alongside stringent environmental regulations, innovative solutions in this field are critical. According to a recent report by MarketsandMarkets, the oil water separation market is projected to reach USD 18 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This growth is fueled by advancements in separation technologies, including membrane-based systems, advanced coalescers, and electrostatic separation. One of the most promising developments is the integration of nanotechnology into oil water separators. Nanostructured materials significantly enhance the surface properties of filters, leading to improved selectivity and throughput. Research indicates that membrane systems incorporating nanomaterials can achieve separation efficiencies exceeding 95%, significantly surpassing conventional methods. Furthermore, real-time monitoring technologies utilizing IoT (Internet of Things) are revolutionizing how operators assess oil water separation efficiency, allowing for dynamic adjustments that optimize performance and reduce operational costs. Additionally, the rise of bioremediation techniques offers an environmentally friendly alternative for treating oil-contaminated water. Utilizing microbes that digest hydrocarbon compounds, this technology not only removes oil but also detoxifies wastewater, aligning with global sustainability goals. According to a research study from the Institute of Chemical Engineers, bioremediation can reduce oil concentrations by up to 99%, marking a significant advance in waste management practices in the oil and gas sector. Overall, the convergence of these emerging technologies is set to redefine oil water separation, making it more efficient, cost-effective, and environmentally considerate for global buyers by 2025.

As we look towards 2025, the evolution of oil-water separation technology is poised to dramatically transform the efficiency and effectiveness of environmental management. Innovative systems are emerging that leverage cutting-edge materials and techniques to enhance the separation process. Among the key features anticipated in the next generation of oil-water separation systems is the integration of advanced membrane technologies. These membranes, engineered with nanostructures, offer superior selectivity and permeability, enabling quicker separation rates and better recovery of valuable resources from waste streams.

Another significant innovation expected in 2025 is the implementation of artificial intelligence and machine learning algorithms in oil-water separation systems. These technologies will optimize operational parameters in real-time, minimizing energy consumption while maximizing throughput. Predictive maintenance features will also be integrated, allowing operators to anticipate equipment failures before they occur, thus improving system reliability and reducing downtime. Furthermore, the use of bio-inspired designs, mimicking natural processes, will provide even more efficient separation methods, reducing chemical usage and enhancing sustainability.

Lastly, modularity and scalability will become prominent traits of future oil-water separation systems. This flexibility allows for systems to be tailored to specific applications, whether for industrial use or in response to environmental emergencies. As global buyers seek solutions that meet regulatory standards while supporting sustainability goals, these innovative systems will not only address current needs but pave the way for a cleaner, greener future in water management.

In the quest for sustainable industrial practices, the demand for eco-friendly innovations in oil-water separation technology is on the rise. As industries increasingly recognize the environmental impacts of their operations, investing in efficient separation processes has never been more critical. The future innovations in this field are paving the way for not only cleaner manufacturing practices but also for significant cost reductions.

The upcoming advancements in oil-water separation technology are centered around the integration of bio-inspired materials and nanotechnology. For instance, researchers are looking towards nature for inspiration, mimicking the abilities of certain plants and animals that excel in separating oil from water. These bio-based solutions promise to minimize energy consumption and enhance separation efficiency, thereby reducing the overall environmental footprint of industrial operations. Furthermore, the introduction of smart sensors and AI-driven systems will allow for real-time monitoring and optimization of separation processes, ensuring that industries can adapt swiftly to varying conditions and maximize sustainability.

Coupled with these innovations is the industry-wide push for circular economy practices. By reimagining waste as a resource, companies are exploring ways to recycle and reuse recovered oil. This not only contributes to reducing waste but also aligns with the global goals of resource conservation and environmental protection. As we head towards 2025, the oil-water separation technologies will not only focus on effectiveness and efficiency but will also stand as testimonies to how industry can harmonize with nature in pursuit of sustainability.

The demand for oil-water separation solutions is poised for substantial growth, driven by heightened environmental regulations and an increasing industrial adoption of sustainable practices. The Oil-Water Separator Market is projected to reach USD 3.92 billion by 2025, reflecting a compound annual growth rate (CAGR) that aligns with the urgent need for efficient wastewater treatment technologies. As industries are pressured to comply with stricter environmental standards, the adoption of advanced oil-water separation technologies becomes a priority.

In parallel, the Water and Wastewater Treatment Equipment market is witnessing a similar rise, as companies seek to enhance their processing capabilities and meet regulatory requirements. The growing awareness and enforcement of environmental policies across various sectors underscore the importance of effective oil-water separation systems. Innovations in filtration, membrane technologies, and chemical treatments are key contributors to this shift, enabling facilities to better manage waste and reduce operational costs.

Furthermore, the dynamics of demand are shifting as industries increasingly recognize the long-term economic benefits of investing in advanced separation technologies. The ability to recover oil and reduce pollutants not only mitigates environmental impact but also presents a viable opportunity for cost savings. By 2025, these trends will define the landscape of oil-water separation and continue to influence global market strategies for buyers seeking reliable and sustainable solutions.

As the global oil-water separator market is expected to reach $4.07 billion by 2032, significant investment opportunities are emerging in cutting-edge oil-water separation technologies. The projected compound annual growth rate (CAGR) of 4.58% underscores the increasing demand for innovative solutions that can efficiently separate oil from water. This growth is largely driven by the rising need for effective water treatment solutions across various industries, including oil and gas, industrial wastewater treatment, and environmental cleanup.

One of the most promising advancements is being spearheaded by researchers and companies focusing on eco-friendly filtration technologies. Ph.D. candidates and research institutions are working tirelessly to develop cost-effective and sustainable technologies that not only enhance separation efficiency but also minimize environmental impact. Innovations such as advanced membrane technologies and smart separation processes are at the forefront of this evolution, providing global buyers with new options to enhance their operational capabilities while adhering to environmental regulations.

Moreover, established companies are unveiling new membrane and resin technologies that promise to revolutionize the separation process. The introduction of high-performance membranes specifically designed for ultrafiltration and membrane bioreactors aims to optimize oil-water separation efficiency, ensuring that industries can manage their wastewater with greater effectiveness. As these technologies mature, investors have a ripe opportunity to enter the market, supporting the transition toward more sustainable practices in oil-water separation, which is crucial for resolving some of the pressing environmental challenges of our time.