- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

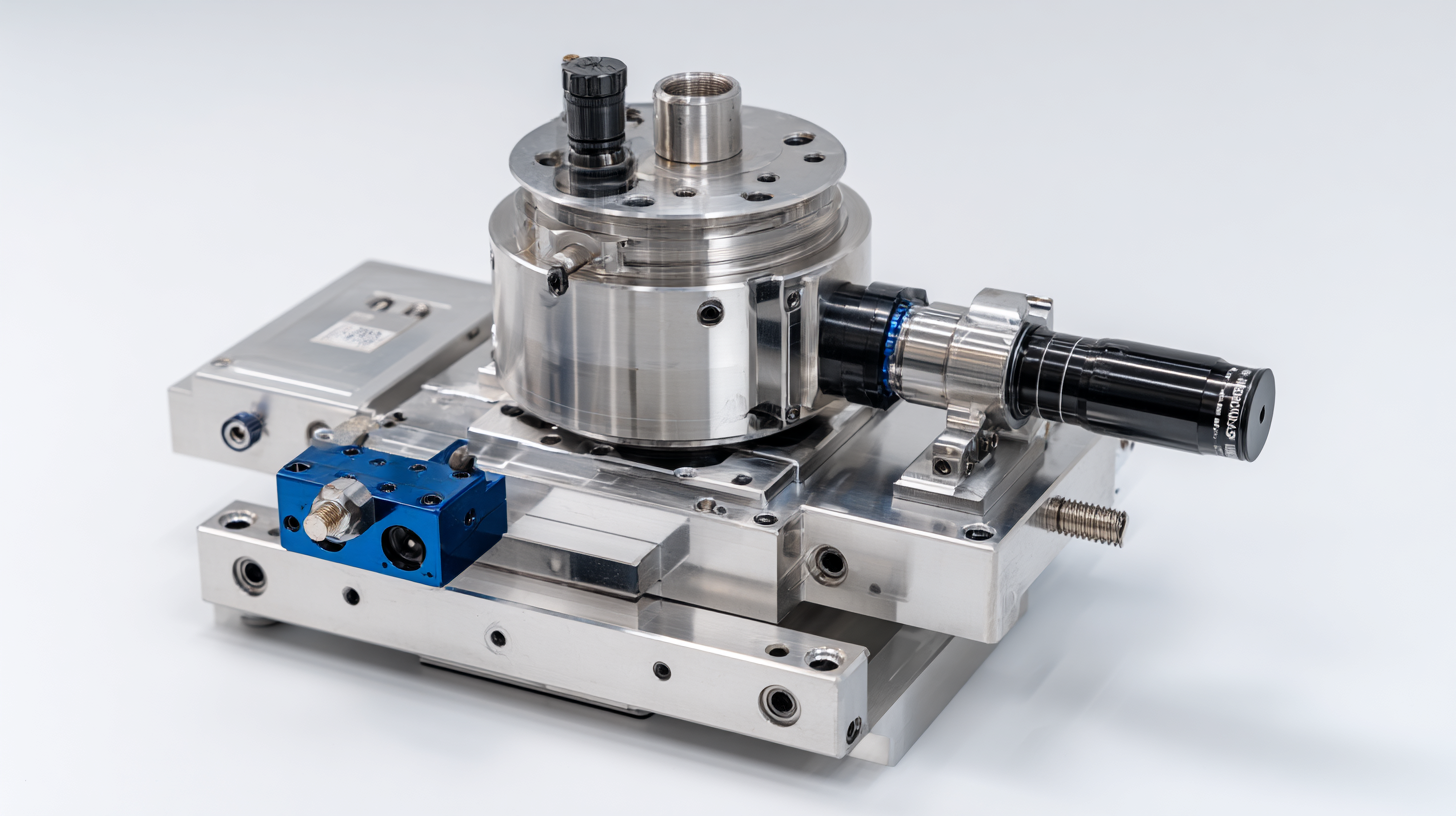

In recent years, the aerospace and automotive industries have witnessed significant advancements driven by the demand for precision engineering and enhanced manufacturing processes. One pivotal innovation facilitating these advancements is the Right Angle Milling Head, which optimizes machining operations by enabling greater accessibility and versatility in tight spaces.

According to a report by Research and Markets, the global aerospace machining market is projected to reach $24.6 billion by 2025, while the automotive sector continues to increasingly adopt advanced manufacturing technologies to improve efficiency and reduce costs. The Right Angle Milling Head plays a crucial role in achieving these objectives, allowing for intricate designs and high-quality finishes that meet the stringent requirements of both industries.

This blog will explore innovative applications of the Right Angle Milling Head within these sectors, highlighting specific examples that illustrate its transformative impact on production practices.

The aerospace and automotive industries are at the forefront of innovation, and the incorporation of advanced right angle milling heads significantly enhances precision machining processes. These milling heads, designed for superior performance, enable manufacturers to achieve tighter tolerances and increased efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, the efficiency improvements from using innovative angle heads can lead to a 20-30% reduction in machining time, a substantial benefit in sectors that prioritize speed and accuracy.

Specifically, the latest designs of right angle milling heads come equipped with features tailored for aerospace applications, such as vibration damping technology and optimized coolant flow systems. These enhancements not only facilitate better surface finishes but also prolong tool life, reducing operational costs. As noted by a leading industry analyst, the adoption of these specialized milling tools can result in an overall productivity boost of up to 25%, critically important for manufacturers aiming to meet escalating production demands in the face of global market competition. The innovation in design ensures that aerospace engineers can push the boundaries of what's possible, enabling safer, more efficient aircraft designs that are crucial in today's evolving aviation landscape.

The automotive industry has seen significant advancements in manufacturing techniques, particularly through the adoption of right angle milling heads. This technology enhances the machining process by enabling multi-directional cutting capabilities, which is crucial for producing complex components efficiently. According to recent studies, the use of right angle milling can reduce cycle times by up to 30% when machining intricate geometries, allowing manufacturers to meet the growing demand for precision in vehicle parts.

Moreover, the integration of composite materials in automotive manufacturing further emphasizes the importance of right angle milling. These materials, known for their lightweight properties and strength, necessitate advanced machining techniques to achieve desired tolerances and surface finishes. Research indicates that switching from traditional metals to composite materials can lead to a 15% reduction in overall vehicle weight, directly contributing to improved fuel efficiency and performance. Right angle milling heads are particularly advantageous in this context, as they facilitate the intricate cutting paths required for shaping these modern materials, ensuring high quality and accuracy.

The combination of right angle milling technology with modern material innovations not only boosts productivity but also supports the automotive industry's shift towards sustainable manufacturing practices. As manufacturers continue to explore new composite solutions, the role of advanced machining techniques will only become more prominent, making them essential for maintaining competitive advantages in a rapidly evolving market.

In the aerospace and automotive industries, the integration of innovative technologies has proven essential for enhancing production efficiency and precision. Recent case studies highlight the successful application of right angle milling heads, showcasing their versatility in complex machining tasks. This milling technique has become a vital element in manufacturing processes, allowing for the creation of intricate parts with tight tolerances. For instance, the adoption of advanced milling solutions has enabled manufacturers to achieve significant reductions in cycle times while maintaining part quality.

Tips for implementing right angle milling effectively include selecting the appropriate tooling for your specific applications and ensuring proper machine calibration. Additionally, investing in operator training can maximize the benefits of these advanced setups.

New advancements in additive manufacturing also complement traditional milling methods, further pushing the boundaries of what's possible in aerospace part production. As manufacturers explore how to control heat management and part accuracy, the synergistic use of milling and additive techniques could lead to groundbreaking improvements in component performance and reliability.

| Industry | Application | Materials Used | Benefits | Challenges | Case Study Reference |

|---|---|---|---|---|---|

| Aerospace | Machining of Engine Components | Aluminum Alloys | Improved Precision, Reduced Cycle Time | Tool Wear Management | Study A |

| Automotive | Manufacturing Gearbox Housings | High-Strength Steel | Enhanced Durability, Cost Reduction | Complex Tooling Setup | Study B |

| Aerospace | Wing Structure Machining | Titanium Alloys | Weight Reduction, Increased Performance | Material Costs | Study C |

| Automotive | Production of Chassis Components | Aluminum and Composite Materials | Improved Efficiency, Flexibility | Training Requirements | Study D |

In the automotive and aerospace industries, the choice between

right angle milling and traditional milling methods can significantly affect production efficiency and product quality.

Right angle milling heads allow for greater flexibility in machining, making it possible to achieve complex geometries with reduced cycle times.

According to recent studies, using right angle milling techniques can enhance surface finish and dimensional accuracy by up to

20% compared to conventional methods, thanks to improved chip removal rates and reduced tool wear.

Tips: To maximize the benefits of right angle milling, ensure proper machine calibration and tool selection based on material specifications. Utilizing

advanced CNC technology with data model-based toolpath generation can further optimize machining processes. This allows for

precise control over cutting parameters, minimizing the risk of defects and rework.

Additionally, it's crucial to consider lubrication systems. Conventional lubrication often falls short in high-speed cutting scenarios where friction and heat generation can lead to chatter and dimensional inaccuracies.

Adopting newer cooling strategies not only mitigates these issues but also prolongs tool life, enhancing overall productivity in manufacturing operations.

In the rapidly evolving landscape of modern manufacturing, right angle milling heads are poised to play a pivotal role in enhancing productivity and precision. According to a recent report by MarketsandMarkets, the global CNC machine market, which includes components like milling heads, is expected to reach USD 100 billion by 2025, driven by advancements in automation and increased demand from the aerospace and automotive sectors. The versatility of right angle milling heads allows for the efficient machining of complex geometries, which is essential for producing lightweight components that meet the stringent requirements of these industries.

Moreover, the integration of Industry 4.0 technologies is set to redefine how right angle milling heads operate. Smart manufacturing solutions, such as Internet of Things (IoT) connectivity and AI-driven analytics, are enabling real-time monitoring and optimization of milling processes. A report from Deloitte indicates that manufacturers leveraging smart technologies can see productivity gains of up to 30%. This trend indicates that right angle milling heads will not only enhance operational efficiency but also contribute to significant cost savings and waste reduction in future manufacturing environments. As the aerospace and automotive industries continue to prioritize innovation, the role of right angle milling heads will undeniably expand, supporting the creation of more sustainable and advanced products.

This bar chart illustrates the innovative applications of right angle milling heads in the aerospace and automotive industries. The data reflects the increasing reliance on these tools in modern manufacturing processes, showcasing a significant growth trend in both sectors.