- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the rapidly evolving landscape of global industries, the demand for high-quality compressed air continues to surge, with the market projected to reach $40 billion by 2025, according to industry reports. Precision engineering, particularly in China, plays a pivotal role in enhancing compressed air quality through advanced technologies and robust manufacturing processes. A critical element in this endeavor is the Compressed Air Filter, essential for removing contaminants and ensuring the reliability of compressed air systems. Research indicates that poorly maintained compressed air systems can lead to energy costs skyrocketing by up to 30%, highlighting the necessity for efficient filtration solutions. As industries strive to meet increasingly stringent quality standards and regulations, mastering compressed air quality through precision engineering has become an imperative, positioning Chinese innovations at the forefront of this essential industrial revolution.

Compressed air is often referred to as the fourth utility in industrial settings, and its quality can significantly affect operational efficiency and product output. In various sectors, including manufacturing, food processing, and pharmaceuticals, the presence of contaminants in compressed air can lead to serious repercussions, such as equipment malfunction, reduced product integrity, and costly downtimes. Understanding and optimizing compressed air quality is thus critical for maintaining high standards and compliance with industry regulations.

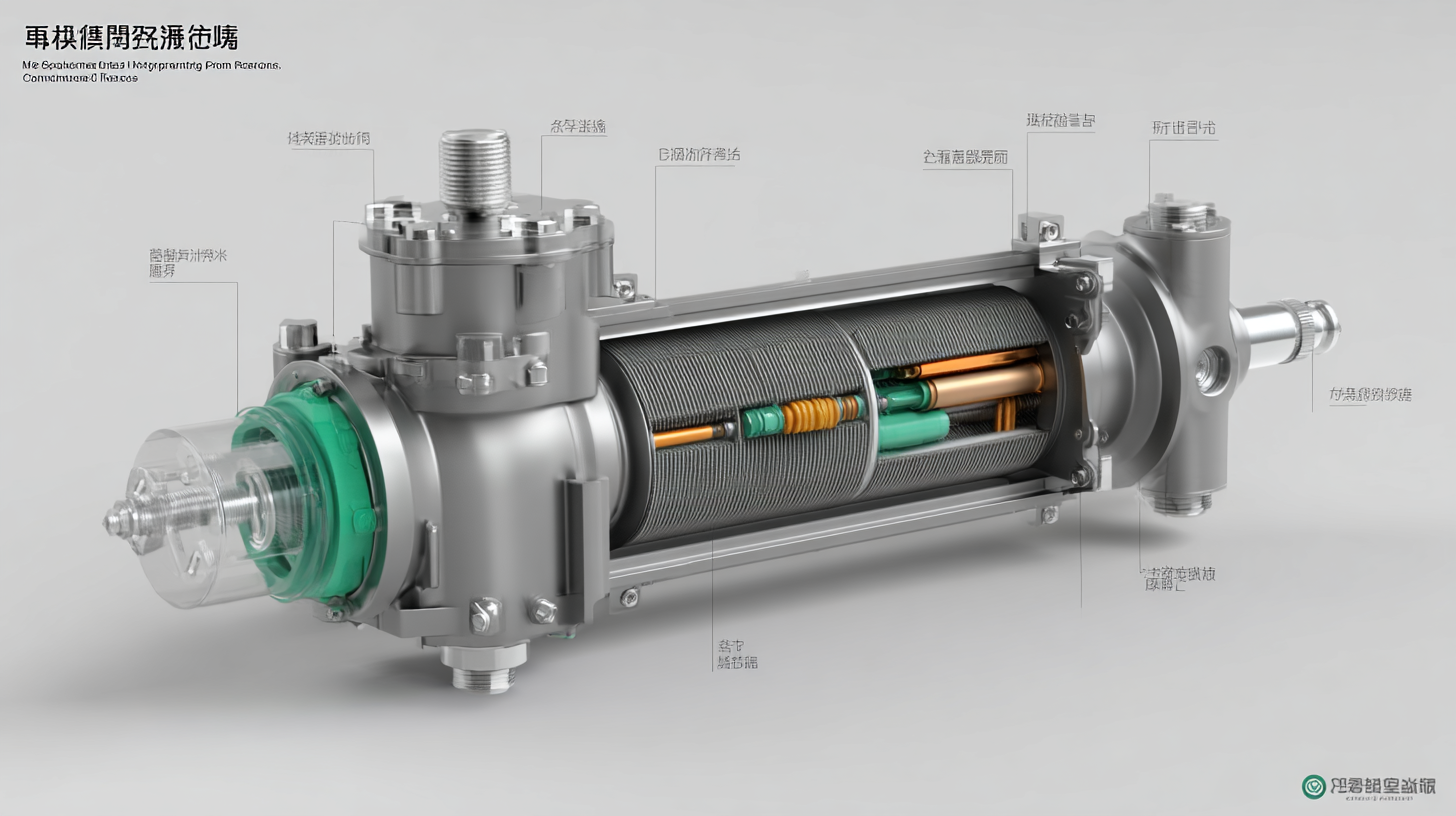

Precision engineering plays a vital role in ensuring that the compressed air systems are equipped with high-quality filtration and drying mechanisms. By leveraging advanced technologies, manufacturers can reduce lubricants, moisture, and particulate matter in the air supply. This attention to detail not only enhances the reliability and performance of machinery but also contributes to overall sustainability efforts. With an increasing global focus on environmental responsibility, industries must prioritize air quality to minimize waste and energy consumption, ultimately leading to a more efficient and sustainable production process.

Compressed air quality is vital for numerous industries around the globe, influencing both efficiency and product integrity. Key factors such as moisture, oil, and particulates can severely compromise air quality, leading to operational inefficiencies and potential damage to equipment. Understanding these variables is essential for ensuring that your compressed air systems remain reliable and effective.

One impactful tip to enhance compressed air quality is to install oil-water separators and moisture traps at strategic points in your system. This can significantly reduce the amount of contaminants introduced into your compressed air stream. Additionally, regular maintenance and inspections of air compressors, including filter replacement, can prevent the buildup of particulates that degrade air quality.

Moreover, utilizing precision-engineered components can play a crucial role in maintaining optimal air quality. Investing in high-quality, efficient filtration systems that are designed specifically for your operational needs can help mitigate contaminants. This enables industries to not only protect their equipment but also ensures the delivery of high-quality compressed air essential for critical applications.

In today's competitive industrial landscape, enhancing compressed air systems through precision engineering techniques is crucial for operational efficiency and sustainability. As the global industrial air compressor market is projected to reach USD 7.7 billion, the demand for high-quality compressed air is intensifying, driven by advancements in technology and eco-friendly initiatives. Precision engineering plays a vital role in optimizing these systems, enabling manufacturers to achieve greater reliability and accuracy. By integrating precision techniques, companies can automate their manufacturing and inspection processes, leading to reduced waste and improved productivity.

Moreover, the latest advancements in sensors for air quality monitoring are transforming how industries manage compressed air systems. A comprehensive review highlighted the significance of cutting-edge air quality sensors, which are essential for ensuring that compressed air remains free of contaminants that can affect product quality and safety. As industries increasingly adopt IoT and AI-driven technologies, the ability to collect and analyze data in real-time is enhancing decision-making processes, ultimately leading to more efficient and sustainable operations. This combination of precision engineering and innovative sensor technologies is set to redefine air quality management across global industries.

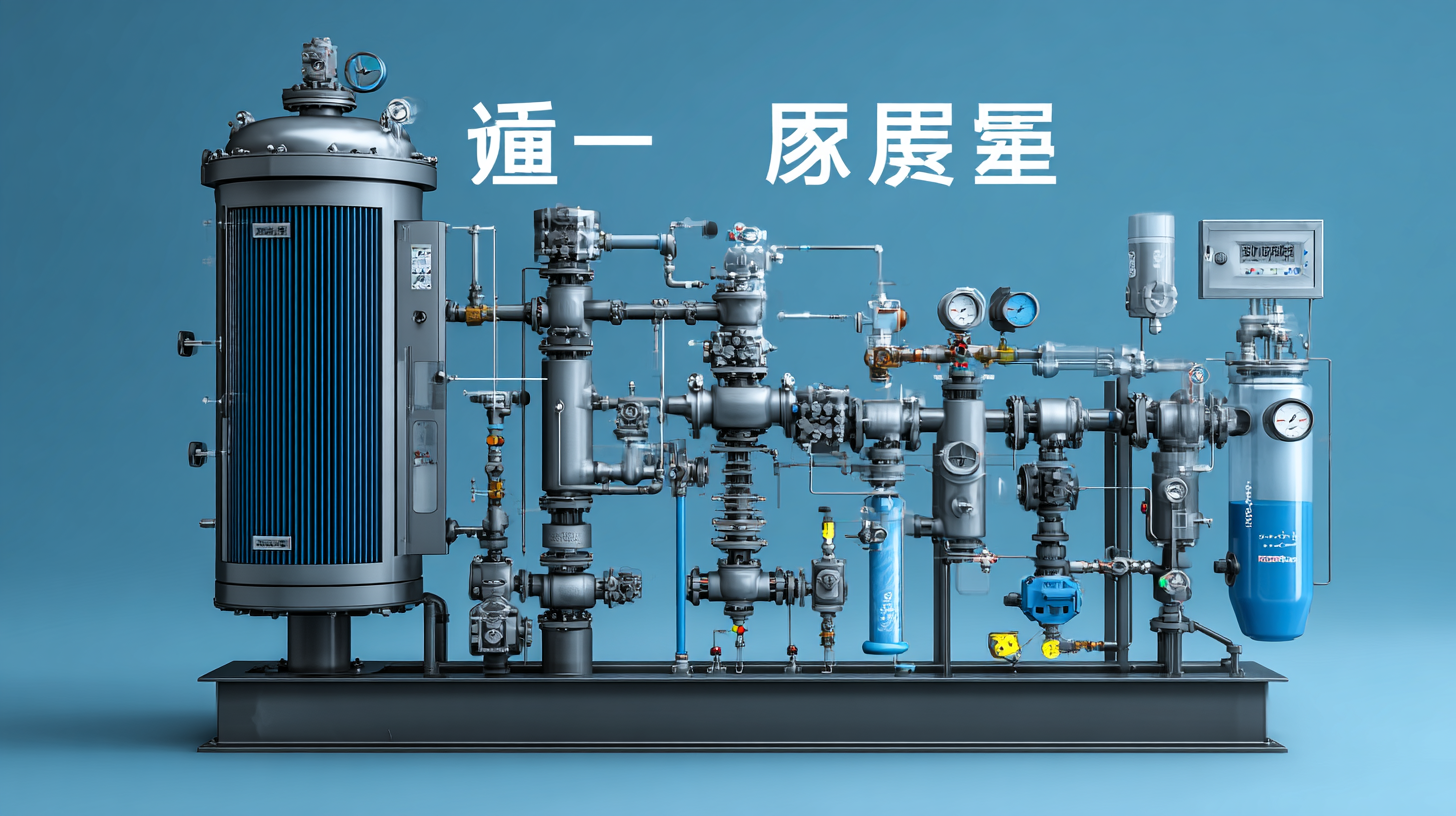

Evaluating compressed air treatment solutions from China reveals a variety of innovative technologies designed to enhance air quality across diverse industries. Chinese manufacturers have made significant advancements in filtering, drying, and purifying compressed air systems, ensuring that industries can achieve optimal operational efficiency while adhering to stringent quality standards. By utilizing precision engineering, these solutions effectively remove contaminants such as moisture and particulate matter, thus extending the lifespan of machinery and improving product quality.

Tips for selecting the right compressed air treatment solution include assessing your specific industry requirements and air usage patterns. Choose equipment that can handle the contaminants prevalent in your environment, and consider the energy efficiency of the systems. Additionally, look for manufacturers that offer comprehensive support and maintenance services to ensure that your systems remain in peak condition.

Another key consideration is the scalability of the compressed air solutions. Industries often face fluctuating demands, and it’s essential to select systems that can be easily adapted or expanded as necessary. Modular designs and customizable solutions can provide significant advantages, allowing for seamless upgrades and enhancements without major overhauls. This adaptability not only future-proofs your investment but also ensures that your air quality remains consistently high as your operations grow.

The future of compressed air quality management is poised for transformative advancements, particularly with the innovative engineering techniques emerging from China. Recent breakthroughs in energy storage systems, notably in compressed air storage technologies, highlight a focus on enhancing energy efficiency and reliability. The development of a high-capacity motor specifically designed for compressed air energy storage exemplifies the precision engineering required to support global industries in achieving superior air quality.

As more companies adopt these advanced engineering solutions, the emphasis on energy efficiency and low-carbon initiatives will become increasingly critical. A recent national certification for energy-efficient compressed air stations demonstrates how companies are actively engaging in the transition toward greener manufacturing processes. This certification not only serves to establish industry standards but also signals a commitment to sustainable practices that can lead to enhanced operational performance. In light of these trends, the integration of cutting-edge technologies into compressed air management is not just beneficial; it is essential for fostering an eco-friendly industrial landscape on a global scale.

| Dimension | Current Trends | Future Projections | Impact on Industries |

|---|---|---|---|

| Air Quality Monitoring | Increased use of sensors for real-time monitoring | Integration of AI for predictive maintenance | Improved operational efficiency and reduced downtimes |

| Filtration Innovations | Adoption of advanced filtration technologies | Development of self-cleaning filters | Lower maintenance costs and extended equipment lifespan |

| Energy Efficiency | Focus on energy-saving technologies | Emerging use of energy recovery systems | Reduced operational costs and environmental footprint |

| Compliance and Standards | Increased regulatory requirements for air quality | Stricter international standards expected | Enhanced quality assurance and customer trust |

| Digital Transformation | Adoption of smart technologies in air systems | Full integration of IoT for operational analytics | Data-driven decisions leading to optimized operations |