- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today’s competitive fabrication landscape, maximizing precision in machining processes is paramount for achieving superior product quality and enhancing operational efficiency. The use of advanced tooling systems, such as the Rubber Flex Collet, has been shown to significantly improve clamping accuracy and reduce the risk of vibrations during high-speed operations. According to a recent industry report by the National Tooling and Machining Association, companies utilizing innovative collet designs experience up to a 20% increase in productivity and a 15% reduction in material wastage compared to traditional clamping methods. The versatility of the Rubber Flex Collet allows it to accommodate a wide range of tool sizes and shapes, making it an essential component in any modern workshop. By implementing this cutting-edge technology, manufacturers can not only enhance precision but also adapt more easily to the varying demands of production schedules.

Rubber flex collets are essential tools in precision work, offering unique benefits due to their specialized composition. Unlike traditional metal collets, rubber flex collets are designed to grip a variety of shapes and sizes securely while minimizing damage to delicate workpieces. Their flexible material allows for slight adaptability, accommodating variations in the dimensions of the workpiece, which is crucial in tight tolerances common in precision engineering.

Rubber flex collets are essential tools in precision work, offering unique benefits due to their specialized composition. Unlike traditional metal collets, rubber flex collets are designed to grip a variety of shapes and sizes securely while minimizing damage to delicate workpieces. Their flexible material allows for slight adaptability, accommodating variations in the dimensions of the workpiece, which is crucial in tight tolerances common in precision engineering.

The primary advantage of using rubber flex collets lies in their ability to maintain a strong grip without the risk of crushing or distorting softer materials. This is particularly beneficial in industries such as woodworking or jewelry making, where precision is paramount. Additionally, the cushioning effect of rubber reduces vibration, resulting in smoother operations and enhanced accuracy in machining processes. By incorporating rubber flex collets into workshop practices, artisans and engineers can achieve higher levels of precision, ensuring that their work not only meets but exceeds industry standards.

Precision in workshop applications hinges on several key factors, particularly when using tools like the Rubber Flex Collet. The stability of the workpiece, alignment accuracy, and consistency in tool performance directly impact the quality of the output. Ensuring that the collet grips the workpiece securely while minimizing vibrations is crucial. This requires regular calibration and maintenance of the tooling setup, as even minor discrepancies can lead to significant variations in precision.

Moreover, advancements in technologies such as machine vision and smart sensors play a pivotal role in enhancing workshop precision. Machine vision systems can assess and adjust the positioning of components in real-time, reducing the margin for error. Similarly, smart sensor technologies can monitor various parameters, providing feedback that aids in maintaining optimal conditions for precision work. As industries increasingly adopt these innovations, the ability to achieve higher accuracy and efficiency will be vital for meeting the evolving demands of manufacturing and production environments.

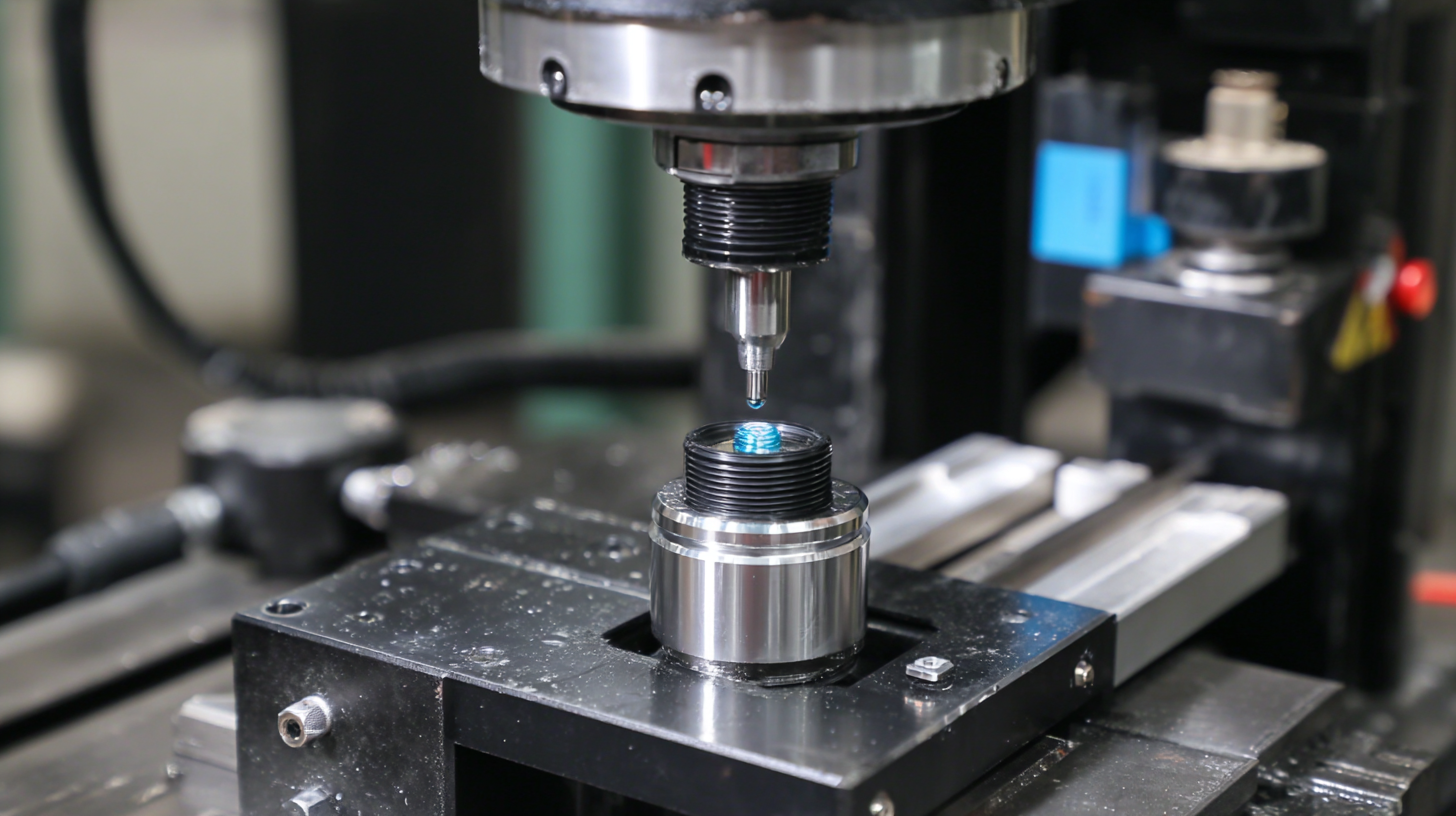

Proper installation and alignment of Rubber Flex Collets are crucial for maximizing precision in machining operations. A study by the Precision Tooling Institute indicates that incorrect alignment can lead to a 20-30% drop in machining accuracy, significantly impacting the overall quality of parts produced. To ensure optimal performance, it is essential to follow systematic installation procedures, starting with the careful cleaning of both the collet and spindle. Any debris or contaminants can affect the fit and lead to vibrations, which ultimately compromise precision.

Once cleaned, aligning the collet is imperative. According to a report by the American Society of Mechanical Engineers, misalignment of tool holders can result in tool wear rates increasing by up to 40%. Use a dial indicator to check the runout and adjust the collet in small increments to achieve the perfect alignment. Additionally, applying the recommended torque during fastening not only secures the collet but also ensures consistent performance, aligning with the industry's best practices. Manufacturers recommend inspecting collet alignment regularly to maintain precision and prolong the lifespan of both tooling and machinery.

To ensure the longevity and precision of rubber flex collets in your workshop, implementing regular maintenance practices is crucial. First, clean the collets after every use to remove debris and contaminants that can affect performance. Utilizing a soft brush or compressed air can help eliminate particles that may accumulate, especially in the grooves. Additionally, periodically inspecting the collets for wear and tear will allow you to identify any issues before they become significant problems, ensuring consistent operation.

Another key aspect of maintenance is proper storage. Collets should be stored in a dry, clean environment away from direct sunlight and excessive moisture, which can degrade the rubber material over time. Furthermore, applying a light lubricant occasionally will reduce friction and protect the rubber from drying out. By prioritizing these maintenance practices, you can maximize the precision and extend the lifespan of your rubber flex collets, leading to improved performance in your machining tasks.

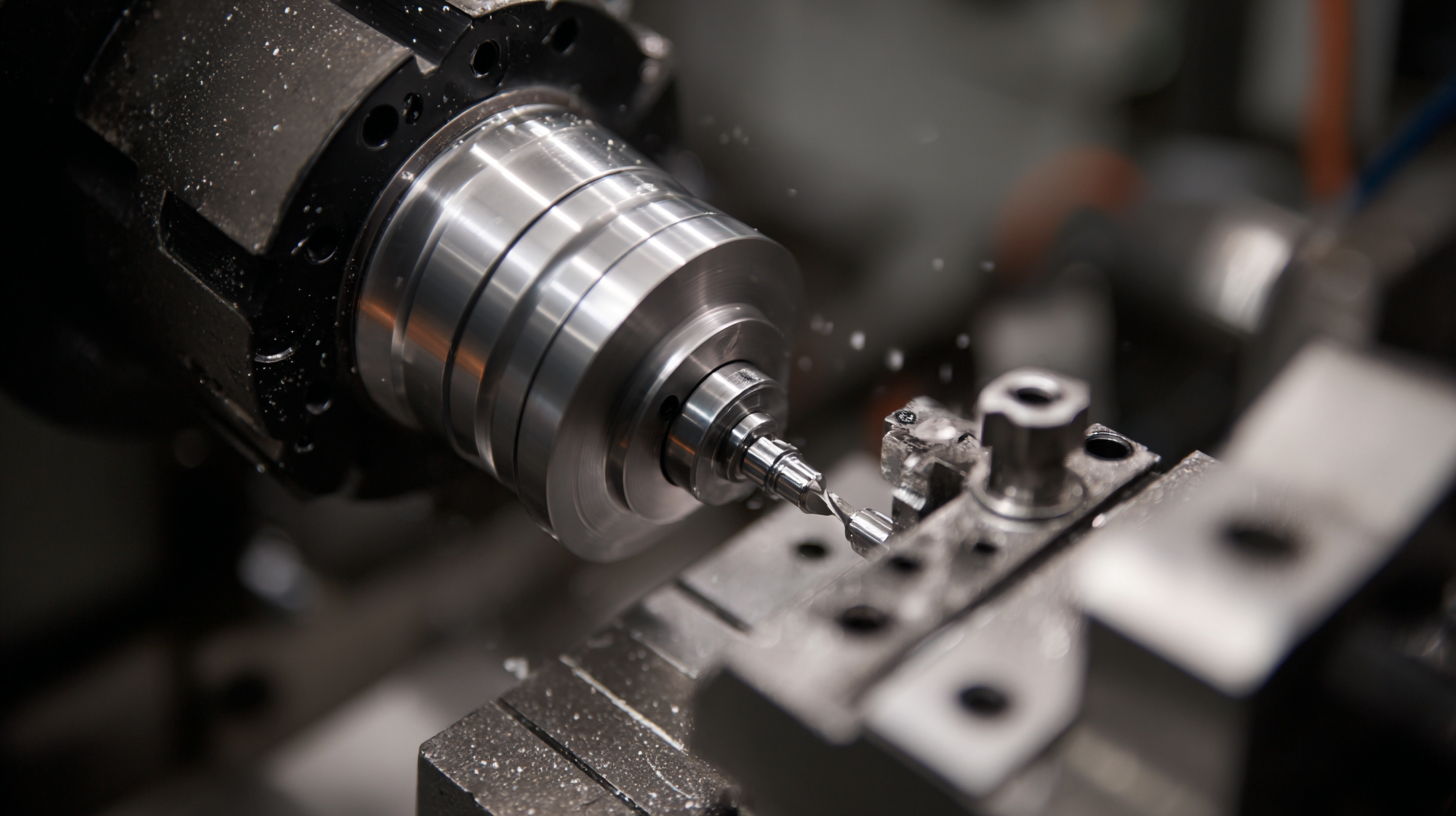

In the manufacturing industry, achieving precision is paramount for ensuring product quality and reducing waste. Case studies reveal that companies implementing Rubber Flex Collets have seen remarkable improvements in their machining processes. For instance, a leading aerospace manufacturer adopted Rubber Flex Collets to address issues with workpiece vibration during high-speed machining. As a result, not only did they enhance the dimensional accuracy of their components, but they also extended tool life significantly. This change led to a reduction in overall production costs and increased throughput.

Another compelling example comes from the automotive sector, where a factory faced challenges with inconsistent part tolerances. By integrating Rubber Flex Collets into their operations, engineers were able to maintain tighter grip on the workpieces, resulting in fewer rejects and rework. The flexibility of the rubber material allowed for better absorption of shocks, thereby stabilizing the tooling during operations. The factory reported a 30% improvement in overall precision, demonstrating how the strategic use of Rubber Flex Collets can lead to substantial gains in productivity and quality control.