- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the highly competitive landscape of precision manufacturing, maximizing CNC lathe collet efficiency is paramount for optimizing production processes and maintaining high quality standards.

According to a recent report from the International Society for Precision Engineering and Nanotechnology, efficiency in machining operations can be enhanced by up to 30% through the strategic implementation of collet systems.

CNC lathe collets, being central to the gripping mechanisms, play a crucial role in ensuring accurate and consistent machining results. As manufacturers strive for leaner operations and reduced cycle times, understanding the alternatives to traditional collet designs becomes essential.

This guide delves into various types of CNC lathe collets and their respective efficiencies, providing actionable insights for manufacturers aiming to elevate their precision machining capabilities and meet the demanding requirements of today’s market.

CNC lathe collets, being central to the gripping mechanisms, play a crucial role in ensuring accurate and consistent machining results. As manufacturers strive for leaner operations and reduced cycle times, understanding the alternatives to traditional collet designs becomes essential.

This guide delves into various types of CNC lathe collets and their respective efficiencies, providing actionable insights for manufacturers aiming to elevate their precision machining capabilities and meet the demanding requirements of today’s market.

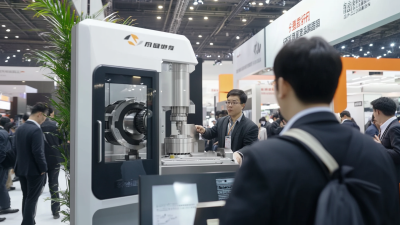

When it comes to CNC lathes, understanding the different types of collets and their applications is crucial for enhancing precision manufacturing. Collets are essential workholding devices that securely grasp the tool shank or workpiece, thus ensuring accuracy during the machining process. There are various types of collets—such as ER, TG, and 5C—each designed for specific applications. ER collets, for instance, are widely used due to their versatility and ability to hold tools of various diameters, making them ideal for setups requiring rapid changes.

Additionally, the incorporation of advanced technologies in CNC lathes has revolutionized their efficiency. For example, modern CNC broaching systems allow for multitasking capabilities, streamlining the setup process while reducing costs. This innovation is complemented by the advancements in Swiss-type machining, which has gained popularity in workshops traditionally equipped with more conventional machines. The sophisticated controls of Swiss-type lathes utilize CNC data to optimize performance, minimizing tool collision risks and reducing waste—a testament to the ongoing quest for increased efficiency in precision manufacturing.

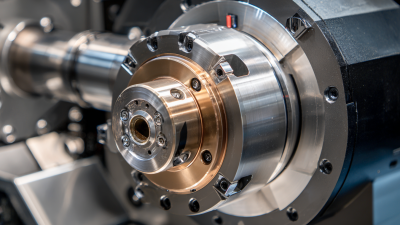

In precision manufacturing, the efficiency of CNC lathe collets is critical for achieving optimal production outcomes. Key factors influencing collet efficiency include gripping force, material quality, and design precision. According to a recent report from the Precision Tooling Association, increasing the gripping force of a collet can enhance workpiece stability by nearly 30%, reducing vibrations that can lead to inaccuracies during machining. Ensuring the right amount of pressure applied to the collet significantly impacts not only the quality of the finished parts but also extends tool life by minimizing wear and tear.

Material selection also plays a vital role in collet performance. High-grade materials such as alloyed steels and advanced composites have shown to increase durability and resistance to deformation under load. A study published in the Journal of Manufacturing Science reveals that using high-carbon alloy steel collets can improve lifespan by up to 50% compared to standard steel versions. Moreover, precise machining of collet dimensions is imperative; tolerances as tight as ±0.005 mm are recommended to maintain alignment and ensure optimal contact with the workpiece. This attention to detail can lead to significant improvements in both part accuracy and efficiency in production cycles.

This bar chart illustrates the key factors influencing CNC lathe collet efficiency in precision manufacturing, highlighting the impact of various parameters on overall performance.

When selecting the right collet for your CNC lathe, it's essential to consider both the

material and the operational requirements of your projects.

Collets come in various designs, such as er, collet chucks, and specialized forms,

each tailored for specific tasks. According to recent industry data, using the

appropriate collet can improve efficiency and precision by up to

30%. This is particularly crucial in

high-stakes settings where every micron counts.

Safety is another critical factor not to overlook when operating CNC lathes. Recent advancements in

equipment safety have led to better protective measures, including shields specifically designed to guard

against rotating chucks and tools. By incorporating these safety devices, manufacturers can significantly

reduce the risk of operator injury while maintaining high manufacturing efficiency. The integration of

safety features not only complies with industry regulations but also promotes

a more productive work environment. By marrying robust

safety practices with the right equipment, businesses can tap into a more streamlined and effective

manufacturing process, further enhancing their bottom line.

Safety is another critical factor not to overlook when operating CNC lathes. Recent advancements in

equipment safety have led to better protective measures, including shields specifically designed to guard

against rotating chucks and tools. By incorporating these safety devices, manufacturers can significantly

reduce the risk of operator injury while maintaining high manufacturing efficiency. The integration of

safety features not only complies with industry regulations but also promotes

a more productive work environment. By marrying robust

safety practices with the right equipment, businesses can tap into a more streamlined and effective

manufacturing process, further enhancing their bottom line.

Maintaining CNC lathe collets is essential for ensuring precision and longevity in your manufacturing process. One of the first steps in proper maintenance is regular cleaning. Collets can accumulate debris and metal shavings over time, which can adversely affect their gripping capability. A simple yet effective cleaning routine involves using compressed air and a soft brush to remove any buildup after each use. Additionally, inspect the collet for any signs of wear or deformation, as even slight imperfections can lead to significant errors in machining.

Lubrication also plays a vital role in enhancing collet performance. Applying a lightweight oil to the collet's moving parts can reduce friction, allowing for smoother operation. It is crucial to use the appropriate lubricant that does not attract dirt or contaminants. Moreover, consider replacing collets that show signs of excessive wear, ensuring that your lathe maintains the high precision required for your manufacturing needs. By adopting these maintenance practices, not only can you extend the life of your CNC lathe collets, but you can also improve the overall efficiency and quality of your machining operations.

When it comes to maximizing CNC lathe collet efficiency, fine-tuning your CNC lathe settings is crucial. Adjusting parameters such as spindle speed, feed rate, and tool offsets can lead to better clamping and more accurate machining. By meticulously analyzing the specific material and tooling you are using, operators can make appropriate adjustments that enhance both performance and precision. This tailored approach not only optimizes the collet's grip on the workpiece but also minimizes vibration, resulting in higher quality finishes.

Another essential factor in achieving optimal collet usage is the selection of the right collet for the job. Understanding the differences between various collet types, such as standard, hex, or precision collets, allows manufacturers to choose the best option for their specific application. Additionally, regular maintenance and inspection of collets helps prevent wear and tear, ensuring consistent performance over time. Implementing these techniques in conjunction with a well-optimized setup can significantly improve CNC lathe efficiency, paving the way for enhanced productivity and precision in manufacturing processes.

| CNC Lathe Setting | Recommended Value | Impact on Efficiency | Notes |

|---|---|---|---|

| Collet Size | Choose based on workpiece diameter | Directly affects grip and stability | Use dedicated collets for different sizes |

| Torque Setting | Manufacturer's recommendation | Ensures proper collet tightening | Revisit after tool changes |

| Spindle Speed | Varies by material (500-3000 RPM) | Balances cut quality and tool wear | Adjust as per material hardness |

| Coolant Type | Water-soluble or oil-based | Enhances tool life and surface finish | Test different types for best results |

| Runout Tolerance | 0.002 mm or better | Crucial for precision machining | Regular measurement checks needed |