- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

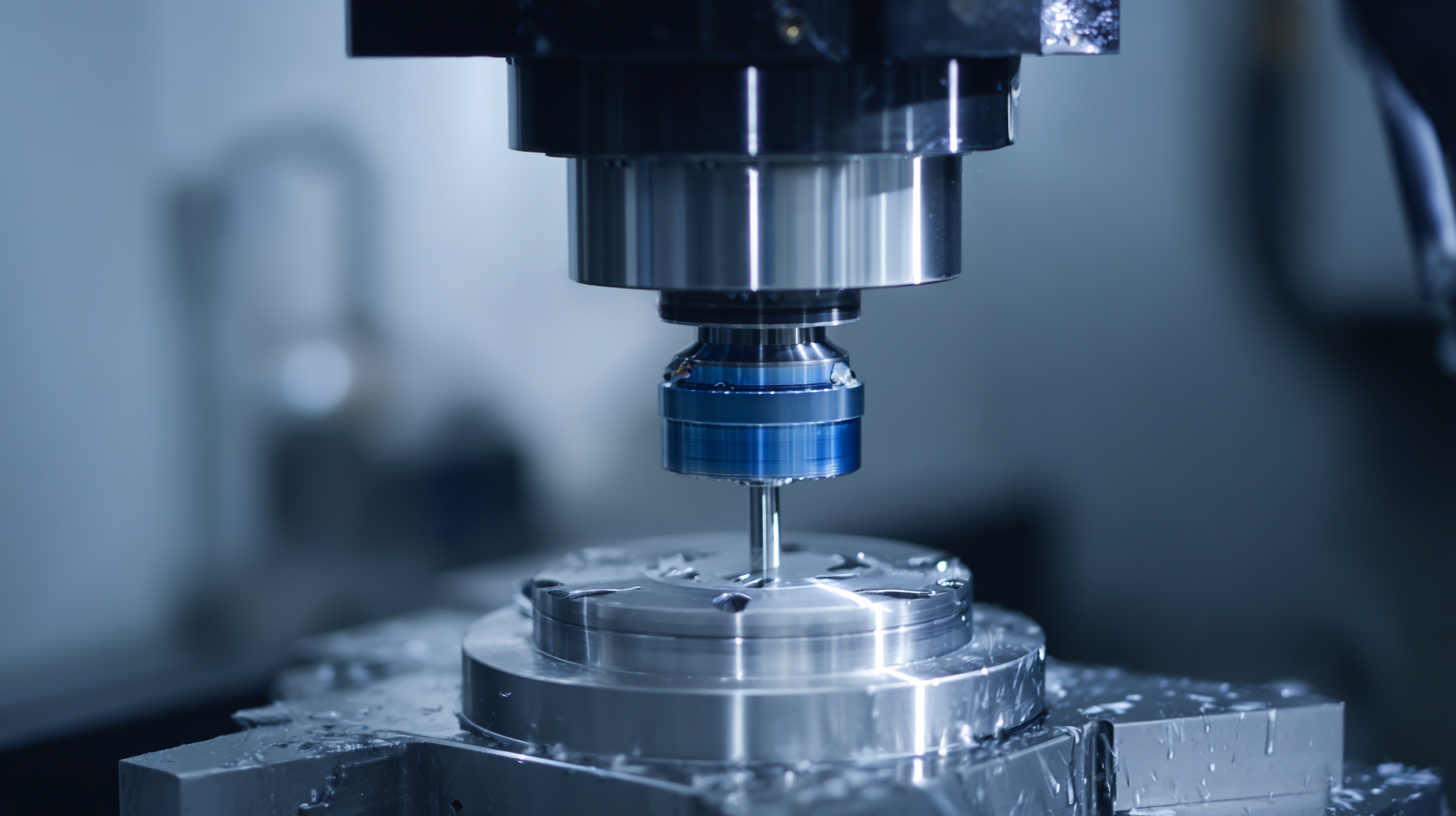

In the quest for enhanced precision and efficiency within modern manufacturing processes, the utilization of advanced tools has become paramount. One such tool making significant strides is the Spindle Angle Head, which offers remarkable benefits by changing the conventional approach to machining. This innovative device enables manufacturers to manipulate spindle angles, resulting in a more versatile and efficient machining process. By facilitating complex geometries and optimizing cutting tools' angles, Spindle Angle Heads have been shown to improve machining precision by an impressive 30%. As industries continue to seek methods to maximize productivity while maintaining high-quality standards, understanding the impact of this technology is essential. This paper delves into the transformative role of Spindle Angle Heads, exploring their mechanisms, advantages, and the ways in which they contribute to the efficiency and accuracy of modern manufacturing systems.

Spindle angle heads have emerged as a game-changer in CNC machining, offering significant improvements in efficiency and precision. According to recent studies, these specialized attachments can enhance machining precision by approximately 30%. This is largely due to their ability to reach complex angles and features without requiring extensive repositioning of the workpiece. Consequently, manufacturers can save time and reduce the likelihood of errors, leading to higher quality outputs.

Spindle angle heads have emerged as a game-changer in CNC machining, offering significant improvements in efficiency and precision. According to recent studies, these specialized attachments can enhance machining precision by approximately 30%. This is largely due to their ability to reach complex angles and features without requiring extensive repositioning of the workpiece. Consequently, manufacturers can save time and reduce the likelihood of errors, leading to higher quality outputs.

When integrating spindle angle heads into your CNC processes, consider the following tips for optimal results: First, ensure that your equipment is compatible with the angle heads to maintain operational efficiency. Second, invest time in training operators on the unique capabilities and settings of these attachments. Finally, regularly maintain and calibrate the angle heads to avoid degradation in performance, ensuring that precision remains at peak levels.

The statistical benefits of using spindle angle heads extend beyond mere precision, also affecting overall productivity and cost efficiency. By reducing cycle times and minimizing the need for secondary operations, manufacturers can increase their output and streamline their workflow. Embracing this technology can ultimately lead to substantial long-term gains in a competitive manufacturing landscape.

Spindle angle heads have emerged as a revolutionary tool in modern manufacturing, significantly impacting production efficiency and reducing cycle times. According to a recent report by the Association for Manufacturing Technology (AMT), incorporating spindle angle heads can decrease machining cycle times by up to 25%. This reduction is primarily due to the ability to perform multiple operations without the need for repositioning the workpiece, which often leads to time-consuming setups and adjustments.

Moreover, companies utilizing spindle angle heads have reported a 30% improvement in machining precision. A study by the Society of Manufacturing Engineers (SME) highlighted that this precision not only minimizes waste but also enhances the overall quality of the components produced. As manufacturers strive for leaner operations, the integration of advanced spindle angle heads offers a compelling solution, enabling faster production rates and minimizing downtime. As a result, manufacturers can respond more agilely to market demands and maintain competitiveness in an ever-evolving industry landscape.

In the world of modern manufacturing, the distinction between traditional machining methods and advanced spindle angle head technology has become increasingly significant. Traditional machining relies on fixed tooling setups, which can limit flexibility and require multiple setups to achieve complex geometries. According to a report by the National Institute of Standards and Technology (NIST), conventional machining can lead to efficiency losses of up to 20% due to time spent in tool changes and setup adjustments.

In contrast, the implementation of spindle angle heads allows manufacturers to enhance their machining capabilities significantly. These advanced tools can pivot and tilt, enabling operators to approach workpieces from different angles without needing to reposition the part. Industry studies have shown that using spindle angle heads can improve machining precision by up to 30%, effectively reducing cycle time and increasing throughput. This innovative approach streamlines operations, making it especially advantageous for complex projects that demand high precision.

Tips: When considering a switch to spindle angle heads, evaluate your current machining processes to identify potential efficiency gains. Implementing these heads can require upfront investment but may result in significant long-term savings. Moreover, ensure that your machining equipment is compatible with the new tooling to maximize the benefits of this technology.

In the modern manufacturing landscape, the integration of advanced technologies such as spindle angle heads and AI-driven solutions has proven critical in enhancing precision and efficiency. Real-world case studies have shown that companies utilizing spindle angle heads have achieved an impressive 30% improvement in machining precision. This claim is supported by industry analyses, which detail how the optimal positioning of tools reduces machining errors and enhances the overall workflow. As highlighted in several reports, the installation of cutting-edge tools not only streamlines processes but also leads to a significant reduction in operational costs.

Furthermore, the integration of artificial intelligence within manufacturing enhances this efficiency. AI applications are transforming production lines by providing predictive maintenance and quality control, which collectively further elevate precision levels. Studies indicate that organizations leveraging AI technologies are experiencing notable improvements in their supply chain management, contributing to a leaner and more responsive manufacturing environment. This convergence of spindle angle heads and AI is a testament to the potential of modern manufacturing practices, revealing pathways for sustained growth and competitiveness in an ever-evolving market.

The landscape of manufacturing is continuously evolving, and spindle angle heads are at the forefront of this transformation. Recent innovations in design have not only advanced the capabilities of these tools but also projected a significant impact on machining efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, improvements in spindle angle head design have the potential to enhance machining precision by up to 30%. This increase is attributed to more efficient chip removal and reduced tool wear, which are crucial in high-speed machining environments.

Looking ahead, the future trends in spindle angle head design focus on integrating smart technology and advanced materials. The adoption of IoT-enabled sensors in spindle angle heads allows for real-time monitoring and adaptive machining, which can further refine precision. A study from the Manufacturing Institute indicates that such innovations could lead to a 20% reduction in operational downtime, enabling manufacturers to achieve higher throughput. As the industry moves toward greater automation and precision, spindle angle heads are poised to become integral to achieving the desired efficiency and operational excellence in modern manufacturing processes.