- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

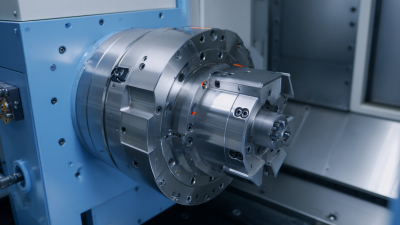

In the realm of precision machining, the pursuit of efficiency and accuracy is paramount. The integration of specialized tooling, such as the Right Angle Milling Head, plays a crucial role in achieving these objectives. According to a report by MarketsandMarkets, the global precision machining market is projected to reach $60 billion by 2025, driven largely by advancements in machine tool technology and tooling solutions. Right Angle Milling Heads allow manufacturers to optimize their machining processes by facilitating intricate cuts and complex geometries that are otherwise challenging to achieve. By enabling access to hard-to-reach areas and enhancing the capabilities of traditional milling machines, these tools significantly reduce cycle times and improve overall productivity. As industries increasingly demand high precision and low production costs, understanding the functionality and application of Right Angle Milling Heads becomes essential for any precision machining operation aiming to stay competitive in this rapidly evolving market.

Right angle milling heads are a crucial component in the landscape of precision machining, offering operators the flexibility to approach workpieces from various angles without the need for complex setups. These versatile attachments effectively reduce setup time and enhance productivity, making them invaluable in environments where efficiency is paramount. Understanding the functionality and advantages of right angle milling heads can significantly impact machining outcomes, enabling precise cuts and high-quality finishes.

Incorporating right angle milling heads into your machining processes allows for enhanced tool accessibility, especially in tight spaces or awkward configurations. This capability not only streamlines operations but also minimizes the chances of potential errors that can arise from frequent repositioning of the workpiece. Additionally, their robust design ensures durability and reliability, which are essential in high-volume production settings where minimizing downtime is a priority. As technology advances, the integration of right angle milling heads continues to evolve, providing manufacturers with innovative solutions to meet increasing demands in precision machining.

| Feature | Importance | Efficiency Impact | Common Applications |

|---|---|---|---|

| Adjustable Angle | Allows for versatility in machining operations | Increases productivity by enabling multiple setups | Complex part designs, mold making |

| Rigid Design | Minimizes vibration and enhances cutting stability | Improves tool life and surface finish quality | High-speed machining, aerospace components |

| Quick Attachment System | Facilitates fast tool changes | Reduces downtime, enhancing overall output | Production lines, job shops |

| Integrated Tool Holders | Offers better tool positioning | Enhances accuracy and repeatability of operations | Precision machining, automotive parts |

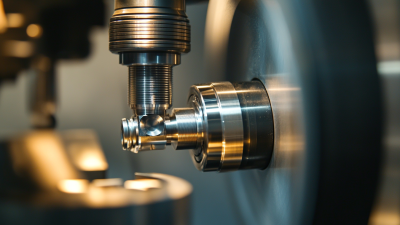

In the realm of precision machining, the use of right angle milling heads has become increasingly vital for enhancing productivity. Their unique design allows for improved access to complex workpieces, significantly reducing cycle times. According to recent industry reports, the adoption of angle heads can elevate productivity by as much as 30%, making them an essential tool for businesses aiming to optimize their machining processes.

One notable advancement in this area is the introduction of center-through-coolant angle heads, which facilitate efficient chip removal, a crucial factor in maintaining tool life and ensuring part quality. Enhanced chip evacuation prevents recutting and improves surface finishes, thus heightening overall operational efficiency.

**Tips for Maximizing Efficiency:**

1. Ensure compatibility between the angle head and the machine spindle to prevent vibrations and inaccuracies during operation.

2. Regularly maintain and inspect the angle heads to ensure they are functioning at optimal performance levels.

3. Consider implementing advanced coolant systems that enhance chip removal to fully leverage the capabilities of right angle milling heads.

By incorporating these strategies, manufacturers can fully realize the potential of right angle milling heads to transform their productivity landscapes.

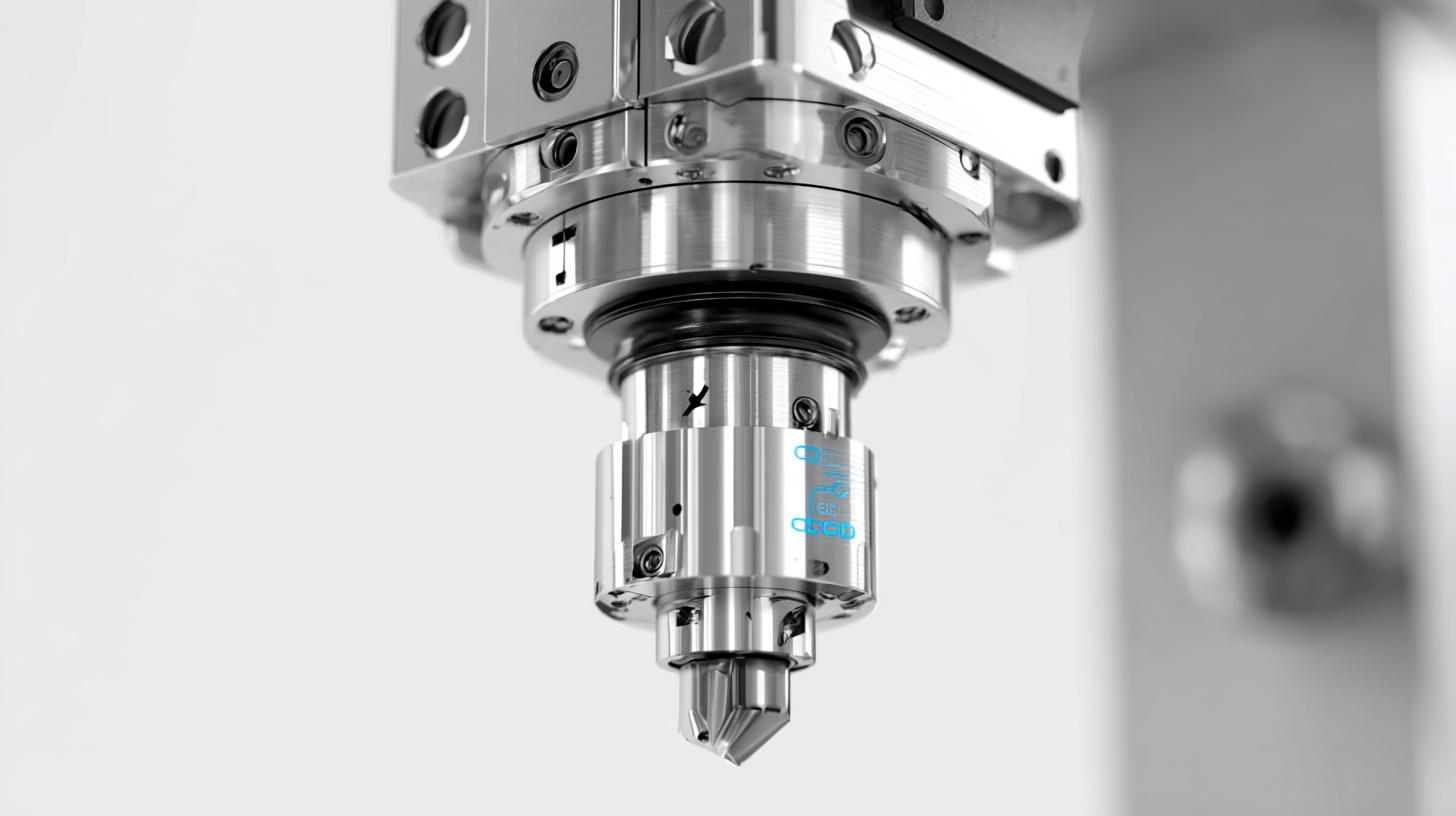

In today's precision machining landscape, right angle milling heads have emerged as a vital component for enhancing efficiency. By integrating an additional machining axis, these angle heads enable manufacturers to access hard-to-reach areas of the workpiece, significantly reducing the need for multiple setups. According to recent industry reports, utilizing right angle milling heads can cut machining time by up to 30%, leading to notable improvements in overall productivity.

To effectively implement right angle milling heads in your workflow, consider the following tips: first, assess the compatibility of your existing milling machines with angle heads to ensure seamless integration. Second, train your operators on the specific adjustments necessary for maximizing the use of these tools, as their unique geometry can require a different approach compared to traditional milling practices. Additionally, keep an eye on tool lifespan; regular maintenance and timely replacements can further enhance performance and consistency in your machining processes.

By incorporating these techniques, manufacturers can unlock the full potential of right angle milling heads, ultimately driving efficiency and precision in their operations.

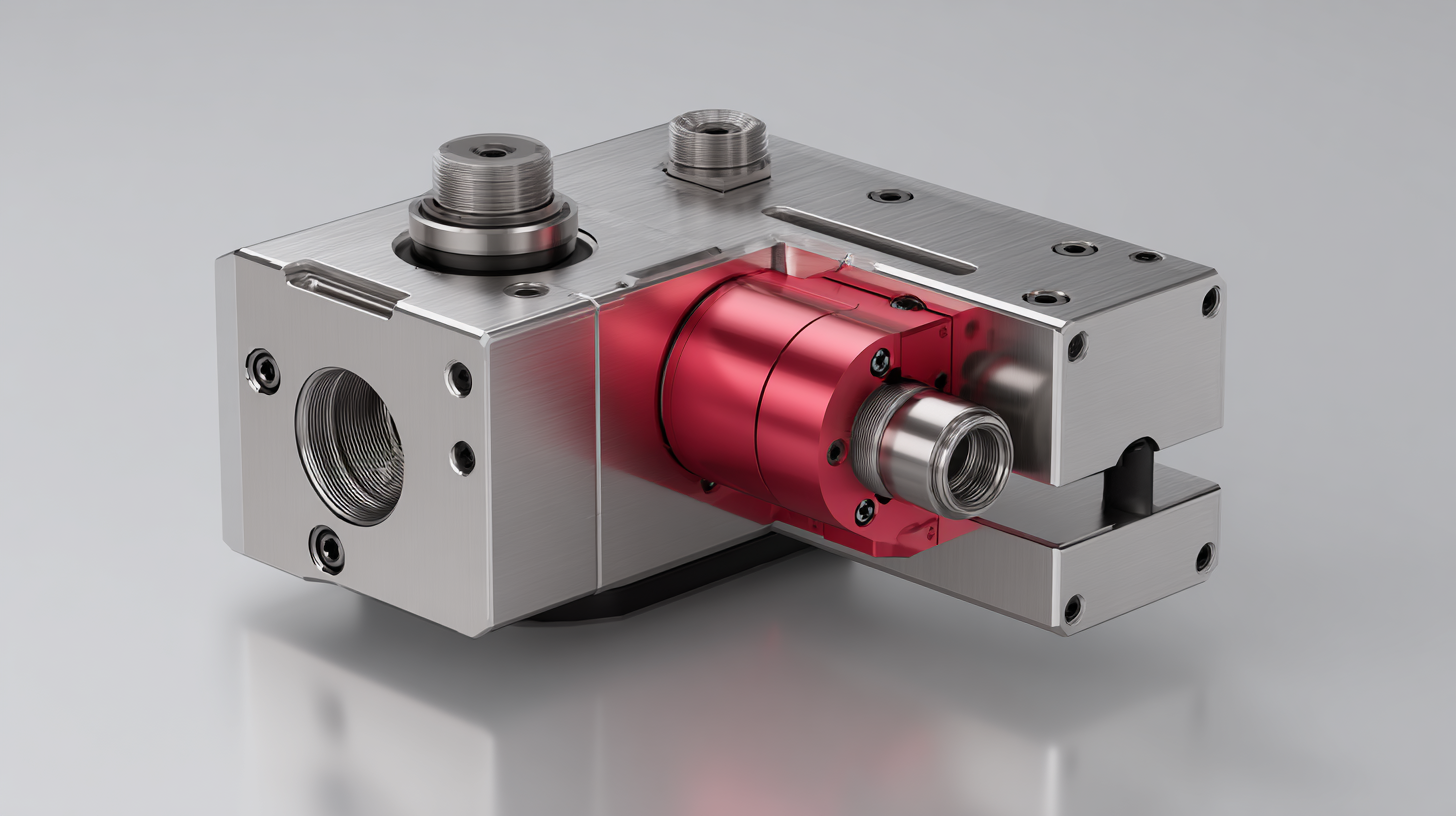

Choosing the right right angle milling head is crucial for maximizing efficiency in precision machining. According to a recent report from the Precision Engineering Research Association, implementing the proper tooling can enhance productivity by up to 20%, reducing cycle times and improving the overall quality of finished components. When selecting a milling head, consider factors such as the material compatibility, size, and taper configuration. For example, a head designed for harder materials will significantly outperform one not suited for such applications.

Tip: Always assess the compatibility of the milling head with your existing machines. A right angle milling head with an improper fit can compromise not only the quality of the workpiece but also lead to increased wear and tear on your equipment, ultimately escalating maintenance costs.

Furthermore, it's essential to evaluate the range of angles and positions your projects may require. A multi-angle capability milling head can accommodate diverse machining tasks, which is particularly beneficial for shops engaging in a variety of jobs. According to a survey by the Association for Manufacturing Technology, shops that utilize versatile tooling report a 15% increase in job adaptability.

Tip: Establish a list of your most common machining tasks and their respective angle requirements before making a purchase. This foresight will guide you in selecting a milling head that aligns perfectly with your operational needs, ensuring optimal performance and efficiency in your works.

When utilizing right angle milling heads in precision machining, avoiding common mistakes is crucial for enhancing productivity and achieving optimal results. One frequent pitfall is neglecting proper setup and alignment. Properly aligning the milling head with the workpiece is essential to ensure accurate cuts and prevent tool wear. Skipping this step can lead to misalignments that cause increased cycle times and potential damage to both the tool and the component being machined.

When utilizing right angle milling heads in precision machining, avoiding common mistakes is crucial for enhancing productivity and achieving optimal results. One frequent pitfall is neglecting proper setup and alignment. Properly aligning the milling head with the workpiece is essential to ensure accurate cuts and prevent tool wear. Skipping this step can lead to misalignments that cause increased cycle times and potential damage to both the tool and the component being machined.

Another mistake often made is overlooking the importance of selecting the right tooling for the job. Each milling operation has specific requirements, and using inappropriate tools can significantly affect the quality of the finished product. It is essential to assess the material properties and desired finish before selecting milling tools. Additionally, not adjusting feed rates and speeds according to the material type can lead to inefficient machining processes that increase the risk of tool failure or surface imperfections. By being mindful of these common mistakes, machinists can maximize the efficiency and effectiveness of right angle milling heads in their operations.