- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the competitive landscape of modern manufacturing, efficiency is paramount, with studies indicating that optimizing machining processes can enhance productivity by up to 40%. One key innovation that has emerged to aid in this quest for efficiency is the Spindle Angle Head. This tool allows for enhanced versatility and accessibility in machining operations, particularly in the complex geometry of workpieces.

According to a report by the National Institute of Standards and Technology, integrating advanced spindle technology not only decreases cycle times but also significantly reduces tool wear, resulting in lower operational costs and improved quality assurance. In this ultimate guide, we will explore practical strategies on how to leverage Spindle Angle Heads effectively, ensuring that manufacturers can unlock their full potential and stay ahead in an increasingly demanding marketplace.

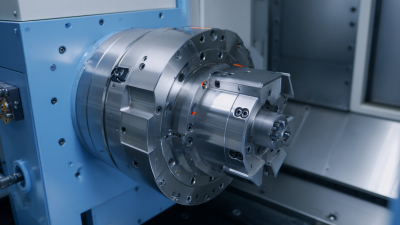

Spindle angle heads are essential tools designed to enhance machining efficiency and flexibility in various industrial applications. These attachments are mounted on the spindle of a CNC machine, allowing cutting tools to operate at various angles. This capability expands the machining possibilities beyond standard horizontal or vertical operations, enabling complex geometries and profiles to be achieved with greater precision. Understanding how spindle angle heads function is crucial for maximizing their benefits in manufacturing processes.

The fundamental operation of spindle angle heads revolves around their ability to pivot and rotate. By providing adjustable angles, they allow operators to engage the tool at optimal positions relative to the workpiece. This not only improves cutting efficiency but also reduces the number of setups required, ultimately saving time and resources. Moreover, spindle angle heads can accommodate a range of tool sizes and types, making them a versatile asset for machining centers. Careful selection and integration of these components into machining workflows can significantly enhance productivity and part accuracy, making them invaluable in modern manufacturing environments.

Spindle angle heads are crucial tools in the machining industry, enhancing productivity and flexibility by allowing multi-angle operations without repositioning the workpiece. According to a report by CIMdata, the adoption of advanced tooling solutions like spindle angle heads can lead to efficiency gains of up to 30% in machining operations. These heads come in various types, each designed for specific applications and industries, making it essential to understand their unique characteristics and benefits.

One common type of spindle angle head is the fixed-angle head, designed for operations at a predetermined angle, typically used in drilling and milling applications. This option is particularly beneficial in high-volume production environments where speed and consistency are paramount. On the other hand, adjustable-angle heads offer versatility, allowing operators to modify the angle as needed. A study from the National Tooling and Machining Association has shown that implementing adjustable-angle heads can reduce cycle times significantly, often by 20% or more, thus maximizing overall machine utilization. Understanding the types available enables manufacturers to select the right spindle angle head for their specific needs, aligning with operational goals and maximizing throughput.

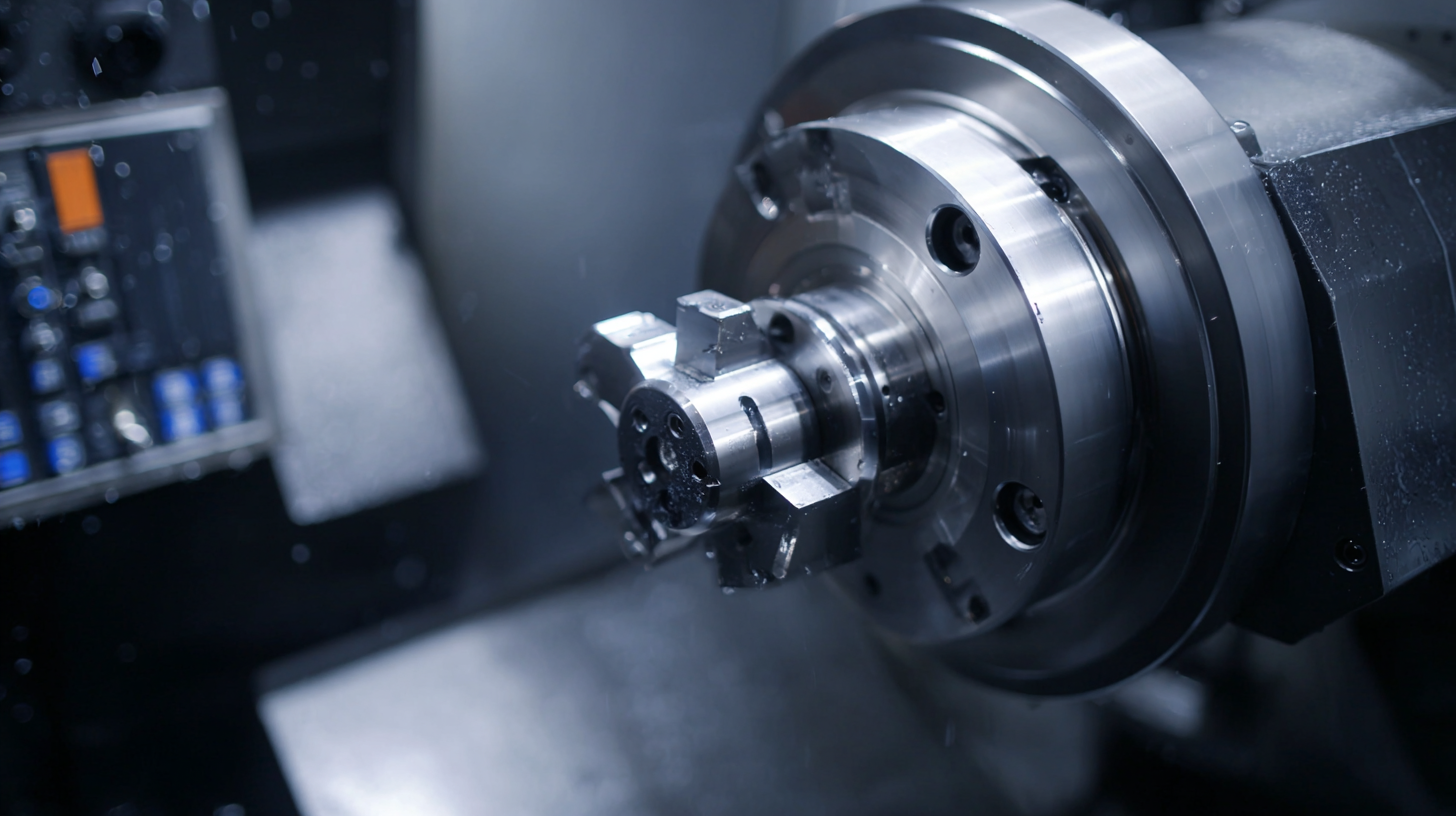

Spindle angle heads are revolutionary tools that enhance machining processes by allowing operators to tackle complex geometries with ease. One of the key benefits of using spindle angle heads is their ability to significantly reduce setup times. Instead of repositioning the workpiece or multiple tool changes, machinists can approach the desired angles directly, resulting in quicker cycle times and increased productivity. This streamlined approach not only optimizes workflow but also minimizes the chances of errors that can arise from frequent adjustments.

Another major advantage lies in the versatility that spindle angle heads offer. They enable multi-axis machining from a single setup, allowing for intricate part designs and complex features to be manufactured more efficiently. This capability is especially beneficial in industries where high precision and rapid turnarounds are essential, such as aerospace and automotive. Overall, integrating spindle angle heads into machining operations can transform productivity and precision, making them indispensable tools in modern manufacturing.

When selecting the right spindle angle head for your machining needs, several key factors must be considered to ensure optimal efficiency and performance. Firstly, the compatibility of the angle head with your existing spindle is crucial. This includes checking the taper size, mounting configuration, and power capacity to guarantee proper fit and operation. Opting for an angle head that aligns seamlessly with your machine will help avoid vibrations and inaccuracies, ultimately improving manufacturing outcomes.

Another important factor is the material and design of the spindle angle head. Different applications require different levels of rigidity and thermal stability, so it's essential to choose a head made from high-quality materials that can withstand the specific demands of your operations. Additionally, consider the range of angles and tool interface options offered by the angle head—this flexibility can significantly enhance your machining capabilities, allowing for more complex geometries and reduced setup times. By taking these factors into account, you can make a more informed decision that boosts your machining efficiency.

Maximizing efficiency with spindle angle heads can significantly enhance your machining processes. One of the best practices is to ensure proper tool selection. Using high-quality tools that are compatible with the specific angles and materials you're working with can lead to better cutting performance and reduced wear. Additionally, always consider the balance of your tools; unbalanced tools can cause excessive vibration, which negatively impacts precision and tool life.

Another critical tip is to optimize your machine settings. Adjusting the spindle speed and feed rates based on the material and tooling used will result in more efficient machining. Monitor the machine's performance and make necessary adjustments to achieve optimal results. Properly configuring the angle head setup can significantly improve productivity, so take the time to ensure it is correctly aligned and secured before starting the operation.

Lastly, routine maintenance of your spindle angle heads cannot be overlooked. Regular inspections and cleaning will help to prevent issues that can lead to downtime and inefficiencies. By maintaining your equipment, you not only prolong its lifespan but also ensure consistent performance. Keeping a detailed log of maintenance activities can also help in identifying patterns that may need addressing.