- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the world of precision machining, the importance of a good Milling Chuck Collet cannot be overstated. Expert machinist John Smith once stated, “The right collet can make or break your workpiece quality.” Collets are essential for firmly holding cutting tools in place. They ensure that every cut is precise and accurate.

However, achieving optimal performance with a Milling Chuck Collet requires attention to detail. Many professionals overlook the importance of regular maintenance and cleaning. A dirty or worn collet can lead to subpar results and wasted material. It’s crucial to inspect your collet frequently for any signs of wear or damage.

Choosing the right collet size and type is also vital for performance. While it may seem straightforward, many users rush through this process. Selecting the wrong collet can result in tool slippage or an improper fit. This not only affects accuracy but can also compromise safety. The key takeaway is the need for diligence in every aspect of using a Milling Chuck Collet. Your work deserves that level of care.

Milling chuck collets are essential for holding tools securely during milling operations. These collets grip the cutting tools with a tight fit, ensuring precision and stability. A well-fitted collet reduces vibrations, which can negatively impact the quality of the finished product. However, selecting the right collet can be tricky.

Understanding collet types and sizes is crucial. There are various designs, such as ER or Jacob's taper, each serving different needs. Keep in mind that wear and tear can compromise their effectiveness. Regular inspection is necessary. Some users may neglect maintenance, leading to issues like tool slippage. It's surprising how often this happens.

Properly maintaining your collets is a responsibility that shouldn't be overlooked. Cleaning debris regularly helps maintain performance. Verify that they are free of cracks and deformities before each use. Not every operator pays close attention to these details, which can result in accidents or poor machining results. Engaging in continuous learning about the tools and their maintenance is essential. This knowledge leads to better performance and outcomes in milling tasks.

Setting up a milling chuck collet correctly is crucial for achieving high precision. Several factors affect this setup, including collet condition, spindle alignment, and tool selection. Regularly inspect collets for wear and damage.

Tip: Always clean your collet before installation. Residue can compromise grip and precision.

Another important aspect is the alignment of the spindle. Misalignment can introduce vibrations and inaccuracies. Studies indicate that even a slight misalignment of 0.001 inches can negatively impact finish quality. This can result in significant time lost during post-processing corrections.

Tip: Use a dial indicator to check spindle alignment before each setup.

Selecting the right tool is equally vital. Different materials require specific tool geometries. Using an inappropriate tool can lead to premature wear. It’s essential to understand the tooling capabilities and limitations for each project. Even expert machinists experience challenges here.

When selecting a collet for your milling needs, precision is key. A good collet holds the tool securely, allowing for precise cuts. Consider the size of the tool you will be using, as this dictates the collet size. It’s essential to choose a collet that matches the tool diameter accurately. Oversized or undersized collets can lead to movement, affecting performance.

One critical tip is to check the material of the collet. Steel and aluminum are common choices, each offering different advantages. Steel collets tend to provide better durability and grip. Aluminum, on the other hand, can be lighter and easier to handle. Think about the type of work you'll be doing. A heavy-duty collet may be necessary for demanding tasks.

Tolerance is another factor to ponder. A collet with a tight tolerance can enhance performance but may require more maintenance. A loose fit provides convenience but can compromise precision. Balance is important here. Too much emphasis on one aspect may lead to issues later on. Understanding your specific milling requirements will guide you in selecting the right collet. Prioritizing features like gripping strength and ease of use can enhance your milling experience.

Maintaining milling chuck collets is crucial for achieving optimal precision. Regular inspection can help identify wear and tear. According to industry reports, up to 30% of machining errors stem from collet issues. Proper maintenance can significantly reduce these errors.

Cleaning collets should be part of your routine. Dust and debris can hinder performance. Use a soft brush and solvent to keep them free of contaminants. It’s recommended to inspect for nicks or bends monthly. Many users overlook this, leading to inconsistent accuracy.

Lubrication is essential but often neglected. A thin layer of oil can enhance gripping power. Reports suggest that well-lubricated collets perform 20% better under pressure. However, be careful not to over-lubricate; this can attract dirt and worsen performance. Regularly review your maintenance practices and adapt to improve longevity. Ignoring these details may lead to frustration and wasted resources.

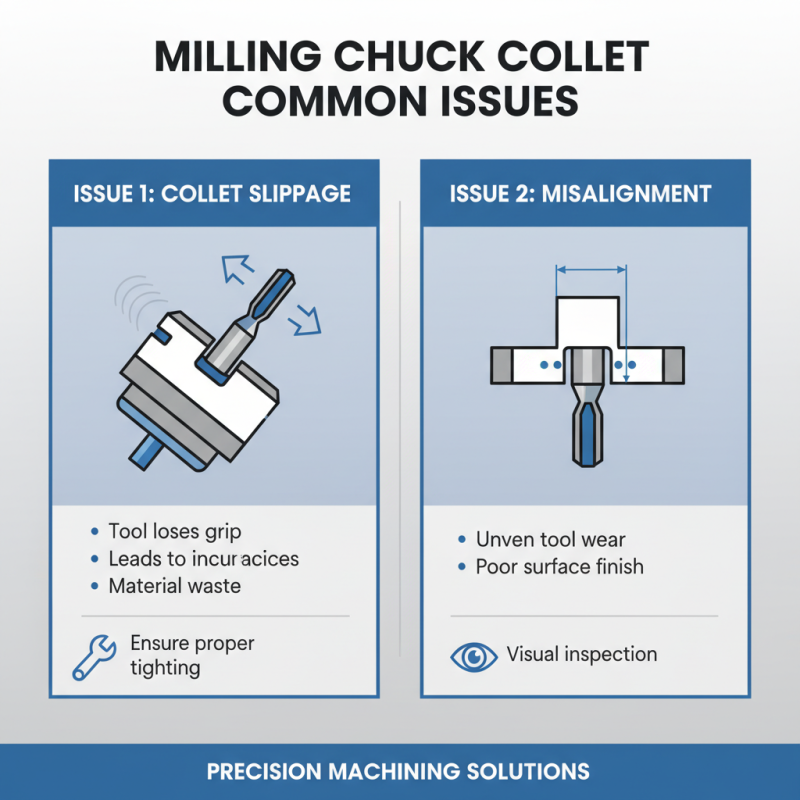

Milling chuck collets are essential tools for precision machining. However, users often face common issues that can impair performance. One frequent problem is collet slippage. This occurs when the tool loses grip during milling operations. It can lead to inaccuracies and wasted material. Always ensure the collet is tightened correctly. A visual inspection can help catch misalignment early.

Another issue is wear and tear. Over time, collets can become worn, affecting the tool's grip. Regularly check for signs of damage, such as cracks or chips. If the collet is not in good shape, it should be replaced. Ignoring this can result in catastrophic failures. Additionally, remember that using the incorrect collet size can lead to poor performance. Ensuring that you have the right fit is critical for optimal results.

Finally, coolant and debris can also interfere with the collet's effectiveness. Keep the area clean and free from contaminants. Establish a cleaning routine to maintain precision and reliability. Addressing these common issues will greatly enhance your milling operations. Each detail matters in achieving the best outcomes.