- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the machining industry, precision is crucial. The Pull Type Collet is a vital tool that plays a key role in achieving this precision. According to a 2023 industry report by Smith & Co., collet-based systems increase productivity by up to 30%. This efficiency stems from their ability to securely grip varied shapes and sizes, making them versatile for different applications.

However, not all users fully understand the operational mechanics of Pull Type Collets. Many overlook the importance of proper adjustment and maintenance, leading to potential inefficiencies. A recent survey indicated that 40% of operators experience issues due to improper use. These misunderstandings can hinder optimal performance and affect the overall output quality.

Despite their advantages, the adoption rate for advanced collet systems remains lower than expected. Some manufacturers hesitate to upgrade from traditional methods. This reluctance can limit access to innovations that improve precision and efficiency. Addressing these gaps can enhance productivity in modern machining environments.

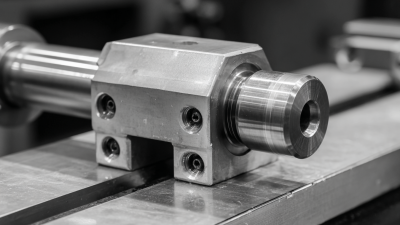

A pull type collet is a vital tool in machining. It secures a workpiece by gripping it firmly during the machining process. Unlike other collet types, it works by pulling the material into the collet body, ensuring tight clamping without excessive force. This method reduces stress on the workpiece.

When using a pull type collet, you will find it's designed for high precision. The collet expands as the drawbar is tightened, wrapping around the tool shank. This design enhances stability, especially at high speeds. However, incorrect installation can lead to slipping or vibration. It's essential to ensure precise alignment when setting up your machine.

Pull type collets cater to various applications, from milling to drilling. They offer versatility but also come with challenges. Over time, wear may affect their performance. Regular inspection is needed to maintain functionality. Users should be mindful of the maintenance process. Always ask yourself if you are using the right tools for your specific tasks. The pull type collet can greatly enhance your work, but it's important to know its limits.

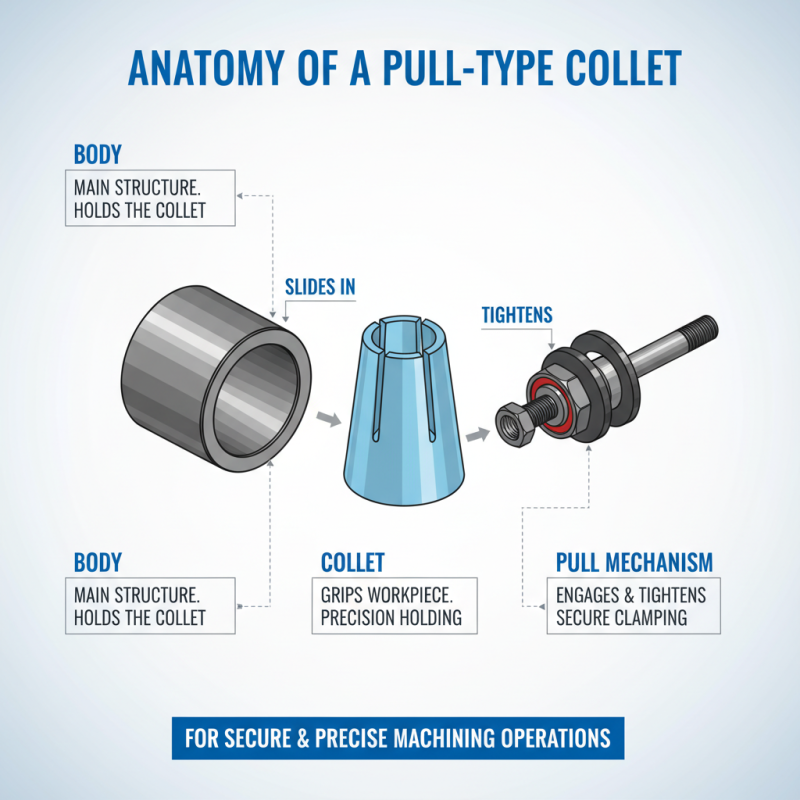

A pull type collet is designed to grip a workpiece securely during machining. The components of a pull type collet include the body, collet, and pull mechanism. The body serves as the main structure, while the collet itself is the part that directly interacts with the workpiece. The pull mechanism is crucial for tightening the collet around the workpiece for precision operations.

One key aspect of a pull type collet is its flexibility. They can accommodate a range of workpiece sizes, making them a versatile choice for many applications. According to industry reports, the efficiency of pull type collets can increase production rates by up to 20%. This makes them particularly valuable in high-speed machining environments where precision is essential.

Tips: Regular maintenance of collets ensures consistent performance. Inspecting the collet for wear can prevent costly downtime. Additionally, choosing the right size for each job maximizes effectiveness. Using a collet that is too loose or too tight can lead to poor machining results. It is worth noting that improper handling can lead to issues that affect accuracy. Experimenting with different collet designs may yield better results in specific applications.

A pull type collet is a crucial component in various machining processes.

Its mechanism relies on a simple yet effective design that enhances the efficiency of clamping tools.

When force is applied to the collet, it contracts, securely holding the tool in place.

This action is essential in precision machining, where stability is key.

Research shows that a properly functioning pull type collet can improve machining accuracy by up to

25%. In addition, it minimizes tool wear during operations.

The design allows for easy loading and unloading of tools, which can save considerable time in production settings.

A recent industry report highlighted that over 70% of manufacturers favor pull type collets due to their reliability.

While the advantages are significant, it's important to acknowledge imperfections in their design.

Misalignment can occur during installation, affecting performance. Regular maintenance is crucial to ensure that the collet works optimally.

Operators must also monitor wear and tear, as this can lead to reduced precision.

Exploring these nuances can contribute to a deeper understanding of pull type collets and their operational mechanics.

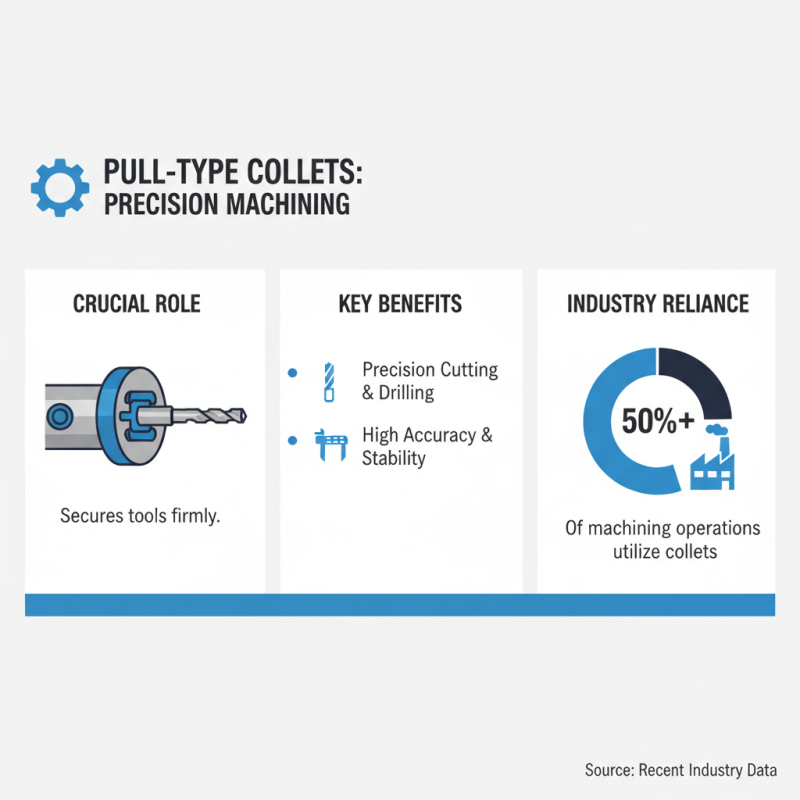

Pull type collets play a crucial role in machining processes. Their ability to secure tools firmly allows for precision cutting and drilling. Many industries rely on these collets for their high accuracy. According to recent data, over 50% of machining operations utilize collets for their effectiveness in maintaining tool stability.

In CNC machining, pull type collets are essential. They accommodate a wide range of tool sizes. The flexibility they offer makes them ideal for complex machining tasks. Surveys show that companies using pull type collets report a 20% reduction in setup times. This efficiency helps in increasing productivity.

**Tip:** Regular maintenance of collets can significantly extend their lifespan. It is vital to keep them clean and free from debris. Consider checking the collet's wear regularly for optimal performance.

Adjustments for different tool diameters can be tricky. Sometimes, users find it challenging to achieve the perfect grip. Ensuring that the collet is properly set is vital. Even small errors can result in tool slippage. This could potentially lead to costly mistakes. Metal shavings and built-up residue can worsen this issue, which is something to watch for.

Always ensure you are using the correct collet for your application. Misalignment can lead to tool breakage. Hence, attention to detail is necessary for effective machine performance.

Pull type collets are popular in various machining applications. They hold tools securely. Understanding their advantages and disadvantages is essential for better machining results.

One key advantage of pull type collets is their gripping strength. They provide a firm grip on the tool or workpiece. This feature enhances precision in operations. Another benefit is their easy setup and changeover. Users can quickly switch collets as needed. However, they may not be suitable for all tool types. Some tools might require a different clamping method.

There are downsides too. Pull type collets can wear out over time. Frequent use may lead to reduced effectiveness. They also can be more expensive than other types. This may be a concern for smaller shops.

Tip: Always inspect the collet for wear before use. A worn collet can impact tool performance. Consider investing in quality collets. It can save money in the long run.

In summary, weigh the pros and cons carefully. Pull type collets could be the right choice for precision, but must be suited to your specific needs.