- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

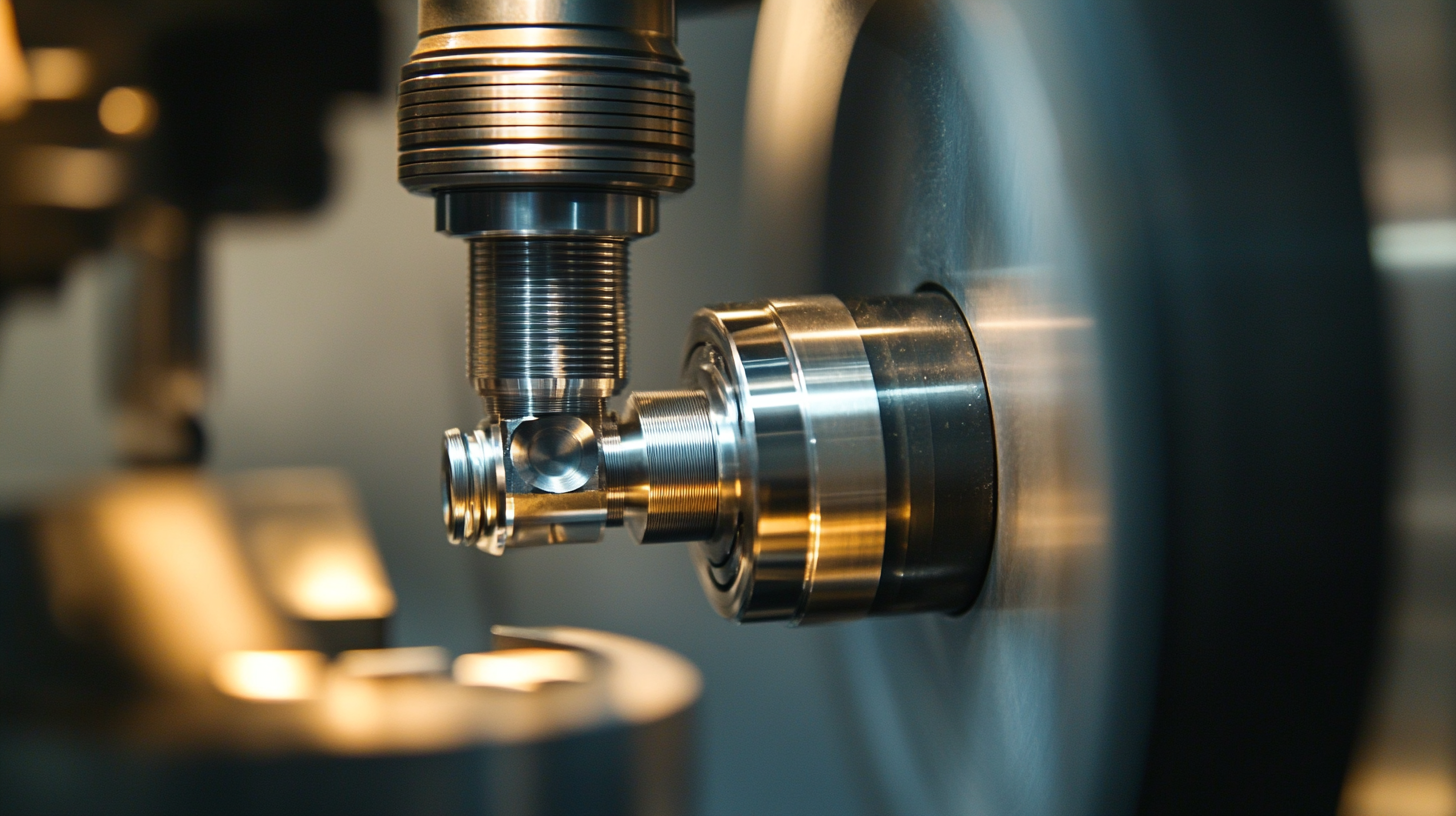

In the ever-evolving landscape of manufacturing, precision has become a cornerstone for success, and the integration of advanced tools such as the

Rubber Flex Collet can significantly enhance operational accuracy.

According to a report by the International Federation of Robotics, the adoption of automation technologies in manufacturing is projected to increase productivity by up to 30% by 2030.

This trend emphasizes the necessity for manufacturers to invest in high-quality components that facilitate precise machining and control. Rubber Flex Collets, known for their versatility and reliability, enable manufacturers to maintain tight tolerances and improved dimensional accuracy in their processes.

By embracing top strategies for leveraging these collets, companies can not only optimize their current operations but also position themselves favorably in a competitive market that increasingly demands exceptional precision and efficiency.

In the ever-evolving landscape of manufacturing, precision has become a cornerstone for success, and the integration of advanced tools such as the

Rubber Flex Collet can significantly enhance operational accuracy.

According to a report by the International Federation of Robotics, the adoption of automation technologies in manufacturing is projected to increase productivity by up to 30% by 2030.

This trend emphasizes the necessity for manufacturers to invest in high-quality components that facilitate precise machining and control. Rubber Flex Collets, known for their versatility and reliability, enable manufacturers to maintain tight tolerances and improved dimensional accuracy in their processes.

By embracing top strategies for leveraging these collets, companies can not only optimize their current operations but also position themselves favorably in a competitive market that increasingly demands exceptional precision and efficiency.

Rubber flex collets have emerged as a crucial component in precision manufacturing across various industries, significantly enhancing operational efficiency and product quality. According to a report by Grand View Research, the global precision manufacturing market is expected to reach $1.6 trillion by 2026, driven by advancements in tooling and fixture technologies, including the adoption of rubber flex collets. These collets provide an essential advantage due to their ability to grip irregular shapes and accommodate varying diameters, which is particularly beneficial in sectors such as automotive and aerospace where components often require precise tolerances.

In the automotive industry, for instance, manufacturers are increasingly utilizing rubber flex collets for their machining processes. A study by Technavio highlights that the automotive precision machining market is poised for substantial growth, with a projected CAGR of 5.1% from 2021 to 2025. The flexibility and versatility offered by rubber collets allow for faster changeovers and reduced setup times, leading to improved production flow and minimizing downtime. This not only boosts productivity but also contributes to cost savings, making rubber flex collets an indispensable tool for manufacturers focused on maintaining high standards of precision and efficiency.

This chart illustrates the precision levels (in micrometers) achieved using different types of rubber flex collets in the manufacturing process. Collet Type E shows the highest precision, making it suitable for applications requiring strict tolerances.

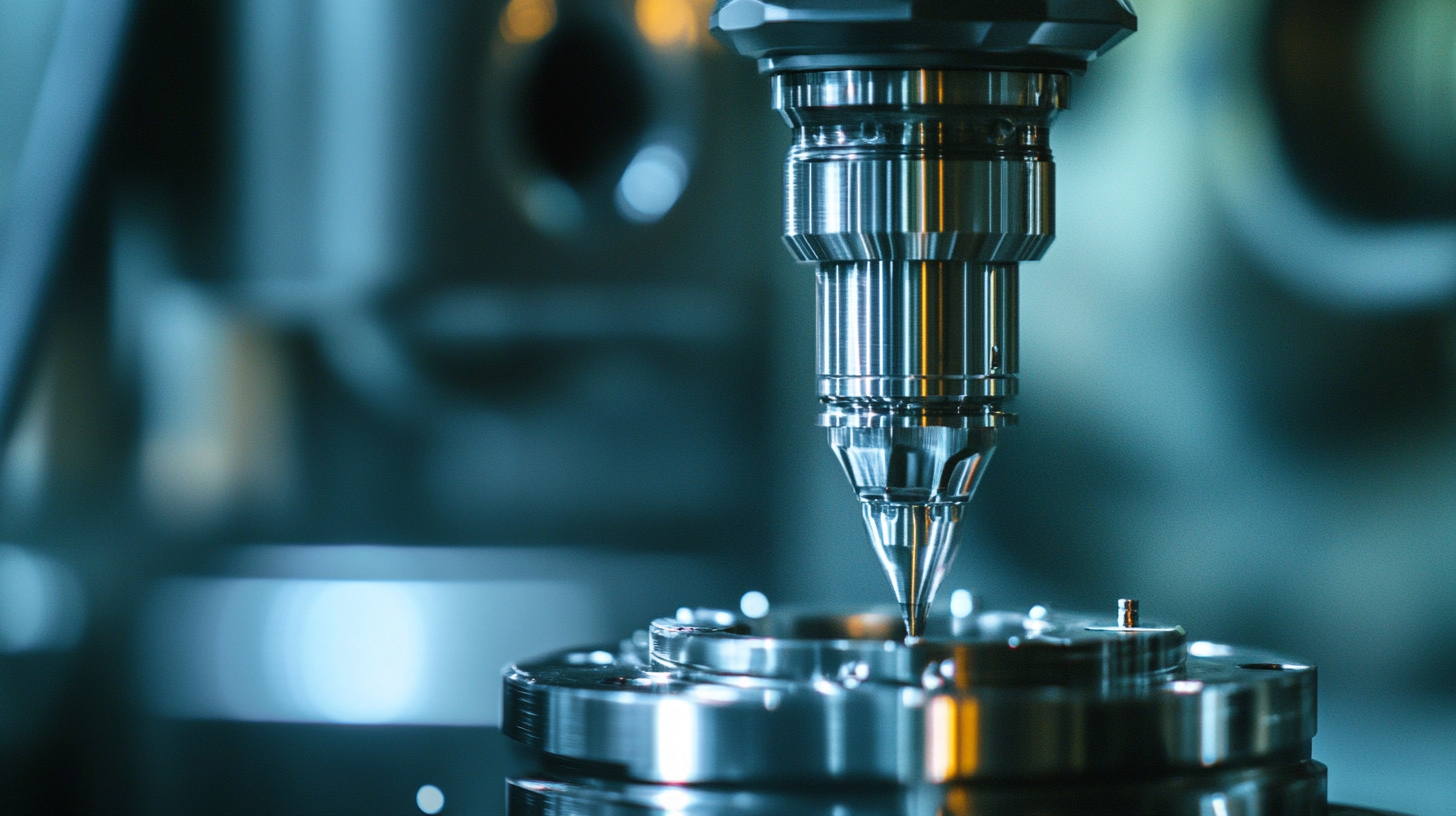

When selecting the right rubber flex collet for your manufacturing needs, it’s essential to consider various factors, such as the material type, collet design, and operational parameters. According to a recent industry report, precision machining processes that utilize high-quality collets can achieve an accuracy improvement of up to 70% compared to standard solutions. This significant enhancement underscores the importance of choosing the right rubber flex collet tailored to your application.

When selecting the right rubber flex collet for your manufacturing needs, it’s essential to consider various factors, such as the material type, collet design, and operational parameters. According to a recent industry report, precision machining processes that utilize high-quality collets can achieve an accuracy improvement of up to 70% compared to standard solutions. This significant enhancement underscores the importance of choosing the right rubber flex collet tailored to your application.

Rubber flex collets have emerged as essential components in modern manufacturing, offering flexibility and precision for enhanced machine performance. These collets are designed to grip various tool shapes securely while accommodating minor misalignments, which is crucial in high-speed machining processes. The use of rubber not only dampens vibrations, improving tool life, but also permits a wider range of tooling options without compromising accuracy. By implementing rubber flex collets, manufacturers can achieve tighter tolerances and more consistent results, ultimately leading to higher quality products.

In practical applications, integrating rubber flex collets into existing machinery can lead to significant improvements in operational efficiency. They are particularly beneficial in challenging environments where traditional collets may fall short due to wear or vibration issues. Moreover, these collets can be quickly adjusted or replaced, minimizing downtime and maximizing productivity. As industries continue to pursue innovations that enhance precision and output, the adoption of rubber flex collets represents a smart strategy for staying competitive and meeting the ever-evolving demands of the market.

| Strategy | Description | Expected Improvement (%) | Implementation Time (Weeks) |

|---|---|---|---|

| Regular Maintenance | Scheduled check-ups and part replacements to ensure optimal performance. | 15% | 2 |

| Precision Alignment | Using laser alignment tools for accurate setup of machinery. | 20% | 4 |

| Training and Upskilling | Educating staff on the usage of rubber flex collets for maximized efficiency. | 10% | 3 |

| Quality Material Selection | Choosing high-grade rubber for collets to improve durability and precision. | 25% | 1 |

| Utilization of Advanced Technology | Implementing CNC machines and automation to enhance collet performance. | 30% | 6 |

In the realm of manufacturing, precision is paramount, and the successful implementation of Rubber Flex Collets has emerged as a transformational strategy. Case studies reveal how various industries have leveraged these advanced collets to enhance their production processes significantly. For instance, in a recent manufacturing initiative, a prominent company adopted Rubber Flex Collets, which led to improved dimensional accuracy and reduced material waste, thereby streamlining operations and boosting overall efficiency.

As sectors face increasing challenges related to sustainability and environmental compliance, the integration of such precision tools not only optimizes production but also aligns with broader eco-friendly practices. By adopting Rubber Flex Collets, businesses can effectively manage pollution control and enhance their monitoring mechanisms. This contributes to a greener manufacturing landscape, addressing the dual challenges of high energy consumption and emissions during production. The synergy between technology and sustainable practices showcases how Rubber Flex Collets are not just tools but catalysts for a promising future in the manufacturing industry.

Precision is critical in manufacturing, and utilizing rubber flex collets can significantly enhance the accuracy of production processes. However, maintaining precision requires adherence to best practices and a keen awareness of common errors. A recent analysis highlights the pitfalls often encountered with collet systems, particularly improper tool assembly and neglecting routine maintenance. According to industry reports, shops that implement rigorous maintenance routines see a 25% increase in production efficiency and a 30% decrease in tool wear.

Precision is critical in manufacturing, and utilizing rubber flex collets can significantly enhance the accuracy of production processes. However, maintaining precision requires adherence to best practices and a keen awareness of common errors. A recent analysis highlights the pitfalls often encountered with collet systems, particularly improper tool assembly and neglecting routine maintenance. According to industry reports, shops that implement rigorous maintenance routines see a 25% increase in production efficiency and a 30% decrease in tool wear.

To ensure your rubber flex collets operate at peak performance, consider the following tips: First, always check the alignment of collets before use. Misalignment can lead to inconsistent results and increased wear. Second, regularly clean and inspect collets to remove debris that can affect their gripping capability. This not only prolongs the life of the collets but also maintains the accuracy of the machinery. Lastly, avoid over-tightening as this can distort the collet and lead to premature failure.

By incorporating these practices, manufacturers can enhance the precision of their operations and reduce the risk of disruptions. Adopting a proactive approach to maintenance will ultimately safeguard production quality and efficiency in the long run.