- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the world of machining, precision and efficiency are paramount, and one of the key components that facilitates these qualities is the Toolholder Collet. As an essential part of various machining operations, the Toolholder Collet secures cutting tools within the machine, ensuring they perform at optimal levels. According to industry expert Dr. James Turner, "The Toolholder Collet is not just a fixture; it is a critical enabler of accuracy and repeatability in machining processes."

Understanding the function and mechanics of a Toolholder Collet is vital for machinists and engineers alike. It provides a gripping mechanism that holds tools firmly in place while allowing for quick changes and adjustments, which is crucial in a fast-paced manufacturing environment. This introduction to Toolholder Collets will explore their design, operation, and the benefits they bring to machining, highlighting why they are indispensable in modern workshops. With insights from seasoned professionals and a closer look at their applications, we aim to shed light on this fundamental toolholder component.

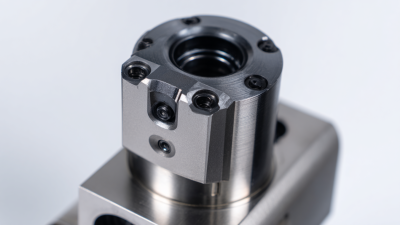

A toolholder collet is a precision device commonly used in machining to securely grip cutting tools, such as drills or milling cutters, within a spindle. Its primary function is to provide a stable and accurate hold on the tool, which is crucial for achieving high-quality machining results. Collets are designed to accommodate various shank sizes, allowing for quick tool changes and precise alignment. The use of collet chucks can enhance machining efficiency considerably; for instance, studies show that the right toolholder can improve machining accuracy by up to 30% and reduce production time by about 15%.

Functionally, the collet operates by tightening around the tool as it is inserted into the chuck. This clamping mechanism increases the contact surface between the tool and the collet, effectively transferring the forces generated during machining, which helps prevent tool slippage. Research indicates that collet designs with improved grip profiles lead to a 20% decrease in tool wear, thus extending tool life and reducing overall operational costs. Furthermore, the precision of the collet minimizes vibrations, which is essential for maintaining tolerances in intricate machining tasks. With the global machining market projected to reach $200 billion by 2026, the role of toolholder collets in driving efficiency and quality in manufacturing processes cannot be overstated.

Toolholder collets are essential components in the machining process, providing a secure grip on cutting tools and ensuring precise adjustments. There are several types of collets, each designed for specific applications and environments. The most common types include split collets, which are highly versatile and used in various machining operations such as milling and drilling, and precision collets, which offer superior accuracy for tasks requiring tight tolerances.

In recent studies, it has been reported that the global demand for collet systems is projected to reach an estimated value of $2 billion by 2025, driven by advancements in automated machining processes and the increasing adoption of CNC (Computer Numerical Control) machinery. Moreover, the implementation of ER collets has become particularly popular in the industry due to their capability to hold tools with high precision while facilitating rapid tool changes. These collets are suitable for a wide range of uses, from metalworking to woodworking, demonstrating their adaptability in meeting various machining needs.

Additionally, hydraulic and shrink-fit collets are becoming commonly utilized for high-speed machining applications. Hydraulic collets are praised for their flexibility and damping capabilities, which can improve tool life and enhance surface finish in critical applications. Reports indicate that the use of hydraulic systems can reduce vibration by up to 50%, resulting in better performance outcomes. In contrast, shrink-fit collets are favored for their rigidity and torque transmission efficiency, making them ideal for high RPM operations where stability is essential. The choice between these collet types ultimately depends on specific machining requirements and desired outcomes, emphasizing the critical role of toolholder collets in modern manufacturing.

| Type of Collet | Material | Application | Advantages |

|---|---|---|---|

| Standard Collet | Steel | General machining | High precision, easy setup |

| Step Collet | Aluminum | Multiple diameters | Versatile, reduces tool changes |

| Collet Chuck | Hardened Steel | CNC machining | Strong grip and stability |

| Hex Collet | Carbon Steel | Bolt machining | Prevents slip during high torque |

| Taper Collet | Bimetal | Lathes and drills | Consistent gripping capability |

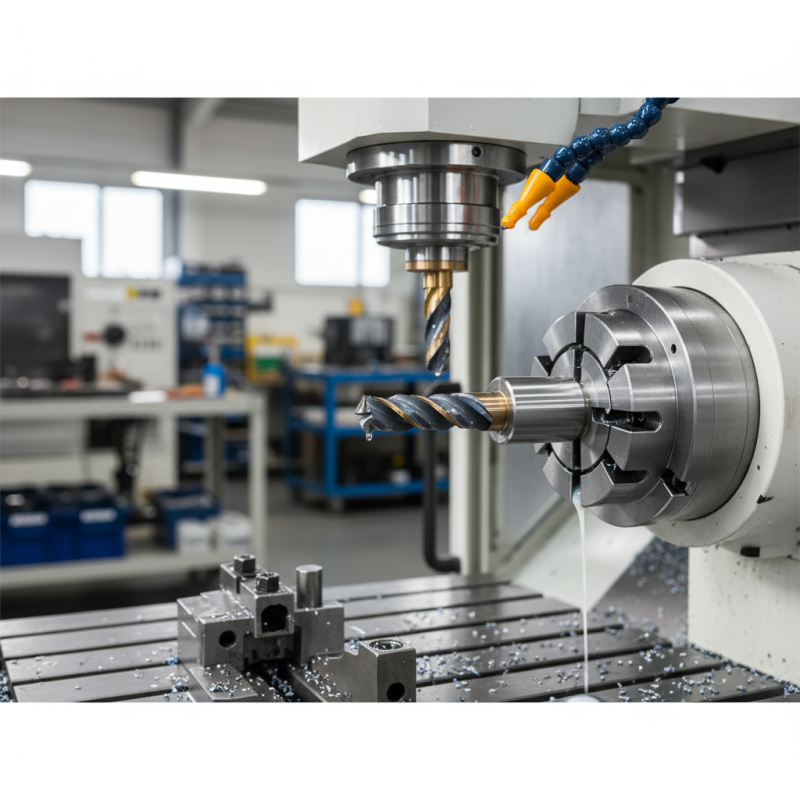

Toolholder collets are essential components in machining operations, providing a secure grip for various cutting tools. The installation of toolholder collets in machining equipment requires precision and attention to detail to ensure optimal performance. To begin the installation process, the machinist must first select the appropriate collet that matches the tool's shank size and shape. This alignment is crucial for achieving stability during machining, as any misalignment can lead to tool slippage or vibration.

Once the correct collet is chosen, it is inserted into the toolholder spindle, which is typically mounted on a lathe or milling machine. The collet is designed with a series of tapered grooves that expand when a drawbar or tightening mechanism is engaged. This expansion securely clamps the cutting tool in place, allowing for efficient and accurate machining operations. After insertion, the machinist must tighten the collet to the manufacturer's specifications, often using specific torque settings to avoid damage to both the tool and the collet. Proper installation not only enhances tool performance but also extends the lifespan of the equipment by reducing wear and tear during use.

Toolholder collets are essential components in machining that play a crucial role in holding the cutting tools securely in place. Their design and functionality are tailored to enhance precision in machining processes. One of the unique features of toolholder collets is their ability to provide uniform clamping pressure, which minimizes tool runout. This consistent grip is vital for maintaining the integrity of the workpiece and achieving a high level of accuracy during operations such as milling, drilling, and turning.

Another noteworthy feature of toolholder collets is their adaptability to various tool sizes and configurations. This versatility allows machinists to swap tools quickly and efficiently without compromising precision. The collets are usually made from high-quality materials that ensure durability and resistance to wear, resulting in prolonged performance under various machining conditions. Additionally, the precision-engineered design of the collet enhances the stability of the tool during operation, which significantly contributes to reduced vibration and improved surface finish on machined parts.

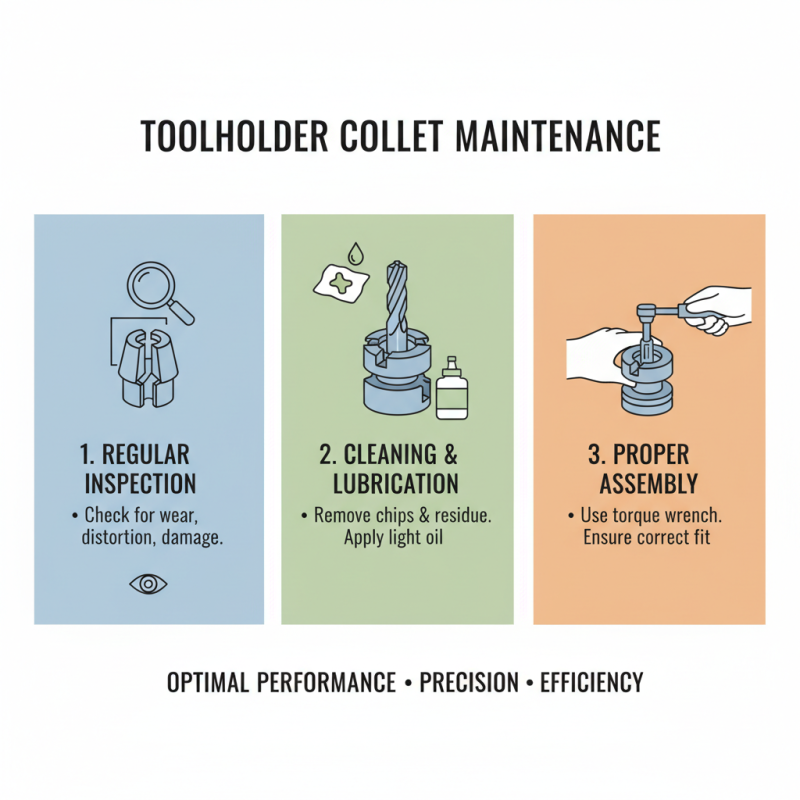

Proper maintenance of toolholder collets is essential for ensuring optimal performance during machining processes. Collets are critical components that secure cutting tools, and any degradation in their condition can adversely affect precision and efficiency. Regular inspection is key; check for signs of wear, distortion, or damage. A simple visual inspection can often reveal issues that may not be immediately apparent.

To enhance the lifespan of toolholder collets, it's advisable to clean them regularly. Particles from the machining process can accumulate and lead to improper attachment of the cutting tools. Use an appropriate cleaning solution and a soft brush to remove debris, ensuring that the collet's gripping surfaces are free from contaminants. Additionally, storing collets in a protective environment can prevent rusting and physical damage; consider using racks or cases dedicated to tool storage.

When using collets, avoid over-tightening as this can lead to deformation. Always follow the manufacturer's specifications for torque settings to ensure that the collet securely holds the tool without compromising its integrity. By adhering to these maintenance tips, you can significantly improve the reliability and performance of your machining operations.