- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

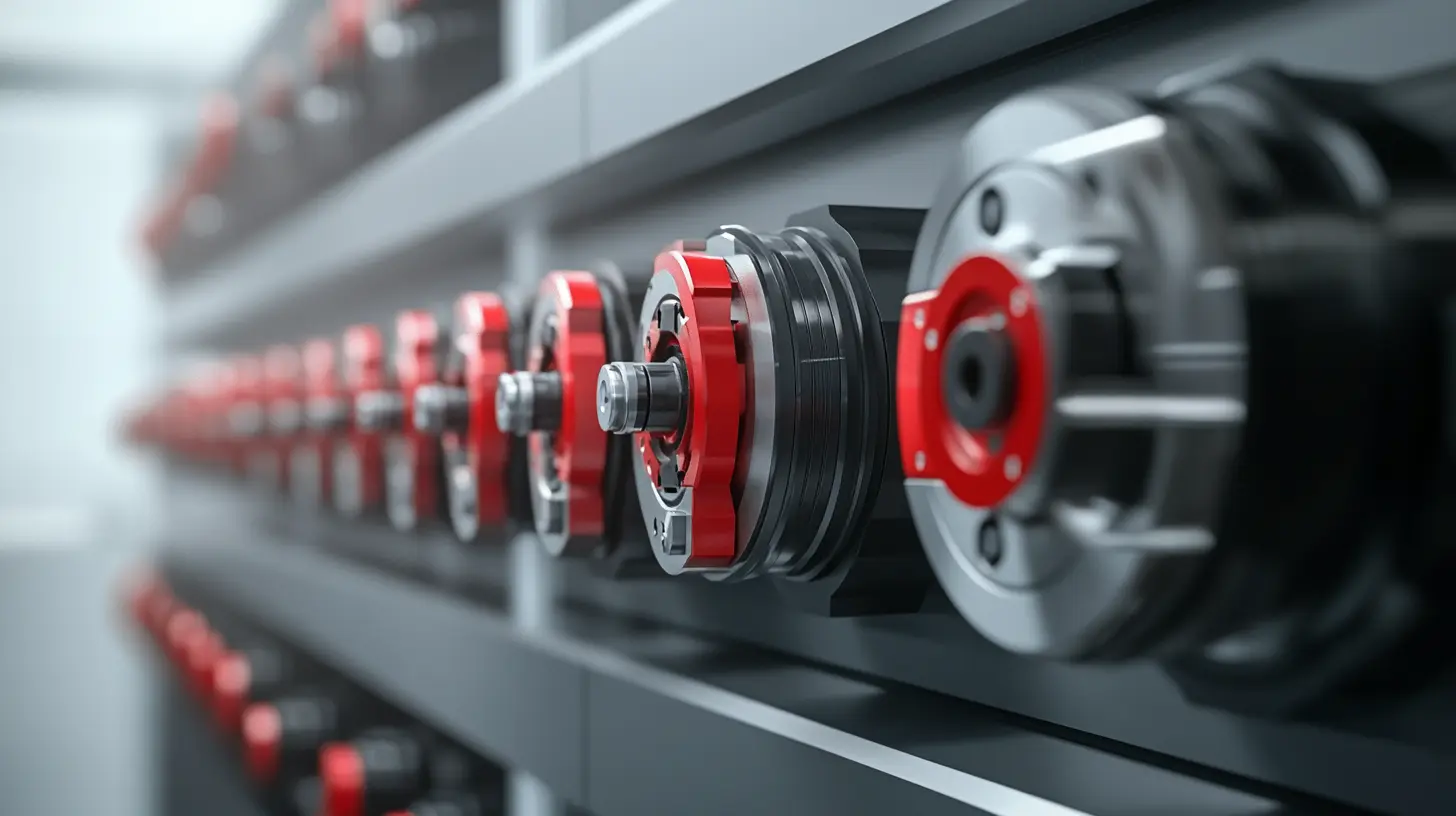

The Toolholding System Collet finds great importance in precision engineering and manufacturing by ensuring perfect and efficient machining processes. Collets are important components that securely hold tools in place, providing the required grip and stability for high-performance CNC operations. An understanding of the specific characteristics and application domains of different collets will greatly help in improving productivity and quality in the manufacture. The present blog intends to provide a detailed description of Toolholding System Collets, including the design variation, strengths, and specific uses in various industries.

Beijing BOD Technology Co., Ltd. was founded in 2011 with a clear focus on peripheral accessories, materials, and auxiliary materials invariably used in modern-day machining solutions. We manufacture tool-holding elements and environmental protection systems such as oil mist collectors, thereby exemplifying quality and innovation. Further, as we dissect Toolholding System Collets, we hope to enlighten our readers on the significance and application of the same and, in doing so, eventually promote the advancement of machining capabilities in the industry.

Understanding the basic functionality and features exclusive to toolholding system collets is essential for their exploration. Collets are a critical element of the toolholding system, whereby they grip the cutting tools and/or accessories securely during machining operations. This design gives precise alignment of the tool and minimizes runout, therefore maximizing machining accuracy. Different styles of collets are there for various applications, ranging from high-speed machining down to heavy-duty cutting. Advanced manufacturing initiatives functioning with automation technology, for instance, robotic arms, have counterparts in the development of mechanized toolholding systems such as collets.Again, whereas dual-arm modern robotics can perform agilely in conducting intricate tasks in many environments, collets have redefined tooling with their flexible yet sturdy means of holding tools through diverse machining operations. Their applicability across heavy operations and diverse sectors in the automotive and aerospace engineering fields proves their worth. Also, the designs for collet technology continue to be improved through various technological advancements from different manufacturers, keeping collets efficient and reliable. Such innovations include design materials and ergonomic considerations, comparable to new functionalities apparent in advanced robotic systems. These innovations enhance production processes and create avenues for increasing precision and productivity among users; thus, it represents the evolution of toolholding.

Collets are very important in any precision machining application. They may be considered as tools properly in their own right and enter into different classifications, each specifying unique conditions for varied machining applications. Understanding the true differences in collet types significantly enhances manufacturing processes in efficiency and accuracy.

Collets ER are probably one of the most common collets and well known for their versatility regarding clamping range and size. ER collets hold an extremely wide range of tool diameter for various cutting tools. With a constant gripping force and subjected to minimal runout specifications, they can maintain their precision in high-speed operations, thus killing the chance for surface finish imperfections. The use of ER collets in CNC machines has become commonplace as they equate superior finishing.

Another collet worth mentioning is the TG collet, having its own design, which gives it a unique super grip. TG collets are very efficient in high torque settings and are widely used in milling and drilling operations. They are built with enough strength to hold large tools while minimizing vibration during operation, making them especially useful during heavy cutting jobs where stability is key.

Last, their self-centering ability has led to frequent use of 5C collets during lathe operations. These collets are self-centering, come in a variety of sizes, and provide a strong grip on turning operations. Quick-change 5C collets allow for fast changes of tools for lesser shop floor downtime and greater productivity. All collet types discussed meet specific needs, further elaborating on the need to select the proper tool-holding system for the best results.

Collets are very vital components of the toolholding systems with advantages that make them really unique from the other toolholder types. The application of this is very even with their characteristics in providing the grip of different diameters of tool shank. This versatile use of simplex changing of various tools with only one holder makes the operation very efficient. The clamping forces of the collets evenly distribute fuller that minimizes vibrations in the heavy working process and makes precise machining.

Highly durable collets also allow you to work at extremely high speeds and conditions and are therefore good for general-purpose work; they can be used for anything milling grinding. Their sleek profile ensures that it does not interfere with the workpiece so operators can achieve very fine shapes because there is not heightened against the other toolholders. In addition, some even possess their design for specialized collets into specific industrial uses such as aerospace and automotive.

Also, one of the most exhilarating characteristics of collets is their ease of use. Most collet systems have uncomplicated clamping arrangements that require few instruments to operate. Thus, it is a time saver during preparation, as well as increases productivity on the shop floor. As the need for precision machining rises, collets have come to stand out in the market as a reliable choice for professionals looking for performance and flexibility in their toolholding solutions.

In the machining world, collets indeed play a critical role, enhancing applications with both precision and efficacy. As opposed to ordinary chucks, collets are toolholding devices designed to grip the cutting tool or workpiece securely with minimal backlash; therefore, any amount of movement is reduced, increasing accuracy and allowing for tighter tolerances in the complex machining process. In simple terms, collets provide a constant clamping force, resulting in stable and reliable operation.

Apart from precision, collets improve machining efficiency. Quick tool exchanges mean a reduction in downtime and maximization of productivity. For many collet systems, the quick-release feature comes in handy when transitioning between various tooling options in environments that demand flexibility. Additionally, They are lightweight and slim, so for high-speed applications, collets also contribute to reducing cycle times and improving throughput.

Another important aspect of collets is their compatibility with different machines and applications. For use in CNC milling, lathes, and other equipment, collets are made to different sizes and shapes to fit a wide gamut of tools. This adaptability not only proves useful in the manufacturing industry but adds to the quality of the final products since they ensure that optimum tool performance is maintained throughout the machining operations. Thus, the introduction of collets into tool-holding systems presents a major step in optimizing high precision and efficiency in contemporary manufacturing.

Collets are vital tools in multiple areas because of their reliability in clamping tools throughout the machining operation. Their adaptability in design allows for various tooling configurations, making them highly desirable for numerous applications. Aerospace, automotive, and manufacturing are industries where collets contribute significant precision and flexibility. Collets in the aerospace industry, for one, allow manufacturers to establish high tolerance machining and precision standards for component fabrication.

In the automotive sector, collets are imperative for the manufacture of parts where quality and performance must be maintained throughout production. From the milling, drilling, and turning application, collets ensure that tools hold their intended location and rotation, reducing the chances of defect. Similarly, in manufacturing environments, especially in mass production, collet systems are applied in the optimization of tool changeover time and improve efficiency of operation. Quickly switching tooling while maintaining precision is vital in meeting production demands.

Outside these industries, a collet also finds application in the medical device industry, where precision engineering is essential. This is capable of securing tiny, intricate tools firmly in place, allowing for the manufacture of high-quality medical instruments and components. Thus, the adaptiveness and accuracy of the collet system have made it the diamond in the crown for different industries where quality and efficiency are considered non-negotiable.

Besides being one of the important factors when considering the correct collet type for toolholding systems, the application range and unique features are also important to consider. Just like any other toolholder, each collet has a function that is specific to a certain machining need. Let us say, for example, that ER collets are more widely used in milling operations due to their versatility and ranges of sizes, whereas precision collets are used mainly where tight tolerances are required.

When making an informed decision, think about the material the collet is made of and its compatibility with your tooling system. Collets that can withstand heat would be advantageous in high-speed operations; however, the softer the materials, the better for the delicate task. So the grip capability and the range of dimensions also come into play; some collets accept a wider workpiece range, which would greatly assist productivity by reducing the changeover times.

Finally, look forward to what your machining processes may need. New technology in manufacturing often present new needs; thus, a collet purchasing decision that will allow for various tools will adequately provide flexibility and adaptability for forthcoming projects. As industries pivot with the times, the way an athlete chooses their decision can redirect the momentum of a whole team forward; thus, the collet decision made today will translate to enhanced operational efficiency and output quality tomorrow.

The maintenance of collets, which form an integral part of the toolholding systems, is deemed to be one of the most important steps in ensuring that their lifespan can be maintained for as long as possible. In their turn, effective maintenance has a far-reaching effect on precision tool performance and reliable service life. Basic maintenance techniques include frequent inspections and cleaning for the detection of any wear and tear before it starts to cause major problems. Over time, debris and oil could become lodged inside a collet, thereby affecting its performance and accuracy. Cleaning with effective solvents and brushes ensures precision functionality for the collet.

Industries are making way for advanced technologies like digital twins, which are transforming maintenance. By simulating environmental conditions and their effects on materials, firms will now revisit maintenance strategies. Here, the maintenance schedule of the collet can be optimized through the analysis of these simulations, thereby minimizing downtime while extending the life of operational units. A much-sought-after predictive maintenance would bring about interventions beforehand when the collet is not performing its best under the ever-changing operational conditions.

Excessive damage can, however, be prevented by adhering to the manufacturer's recommendations regarding usage and maintenance. Examples of practices that would keep the collets in good standing include regular lubrication and proper storage when not in use. Following these maintenance principles and taking advantage of modern technologies will benefit the collets' lifespan and better machining returns in several application areas.

The evolution of future toolholding systems and collet apparatus will head towards drastic transformations, especially in the burgeoning fields of automation and artificial intelligence. As industries stepped in on smart manufacturing, the demand for higher precision and efficiency toolholding mechanisms increases. Collets hold tools tightly, but they will adjust to the new production conditions by incorporating advanced systems to monitor its performance and peedictive maintenance

Sustainability is another developing area in which toolholding is focusing. Manufacturers are now developing materials and designs that improve performance and, on the other hand, take care of the environment. Biodegradable components and energy-efficient manufacturing processes are now emerging as solutions in line with the overall trend toward environmental consciousness in the industrial space.

As we move towards the year 2025, players in the industry have moved to adopting digital tools on their toolholding systems. Real-time data capture and processing have been enhanced by the adoption of IoT technology (Internet of Things) used across the organizations for smarter inventory and efficiency in optimizing processes. With this marketing trend, there will be even more personification of applications, which would strengthen the role of collet tops in modern manufacturing landscapes.

Collets are essential components in toolholding systems that play a vital role in enhancing the efficiency and accuracy of manufacturing processes.

ER collets are known for their versatility and range of clamping capacities, accommodating various tool diameters and offering consistent gripping force and minimal runout during high-speed operations.

TG collets are particularly effective for high-torque applications, often used in milling and drilling operations due to their superior grip and minimal vibration.

5C collets are commonly used in lathe work because of their self-centering ability, robust holding capacity, and quick-change capability that allows for efficient tool transitions.

The future of toolholding systems is expected to change through advancements in automation and artificial intelligence, leading to enhanced precision and efficiency in collet technology.

The emerging sustainability trends in the toolholding sector include the exploration of materials and designs that enhance performance while reducing environmental impact, such as biodegradable components.

IoT technology is impacting toolholding systems by enabling real-time data capture and analysis, leading to smarter inventory management and process optimization.

Modern collets offer benefits such as sophisticated monitoring systems for performance tracking and predictive maintenance, aligning with the demands of smart manufacturing.

Collets contribute to operational efficiency by ensuring secure tool grip, allowing for optimized processes, and reducing downtime with quick tool changes and adaptability to various applications.

Customization plays a crucial role in the future of toolholding systems, allowing for tailored solutions that meet specific application needs, thus reinforcing the importance of collets in modern manufacturing.