- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Precision tooling occupies an honored position as the backbone of present-day competitive manufacturing. A major part of such a claim is the collet chuck, which is vital for accurately and efficiently gripping tools and workpieces. Reports say that the worldwide collet chuck market is foreseen to grow to USD 2.2 billion by 2026, thanks to the increasing demand for advanced manufacturing technologies and automation. So, as companies strive for productivity and less downtime, understanding the certifications and standards pertinent to collet chucks will ensure that quality and compliance are not compromised during production processes.

Started in 2011, Beijing BOD Technology Co., Ltd. specializes in peripheral accessories, materials, and auxiliary materials that are essential for the manufacturing sector. Built around products such as angle heads and oil mist collectors, this company is positioned to serve industries that require high-quality tooling solutions. As the industry moves forward, knowledge of all certifications of Collet Chucks can greatly help manufacturers gain a competitive advantage in tackling their production complexities while increasing operational efficiencies. This guide will describe the top 5 essentials regarding collet chuck certifications for manufacturers so that they can make informed sourcing choices.

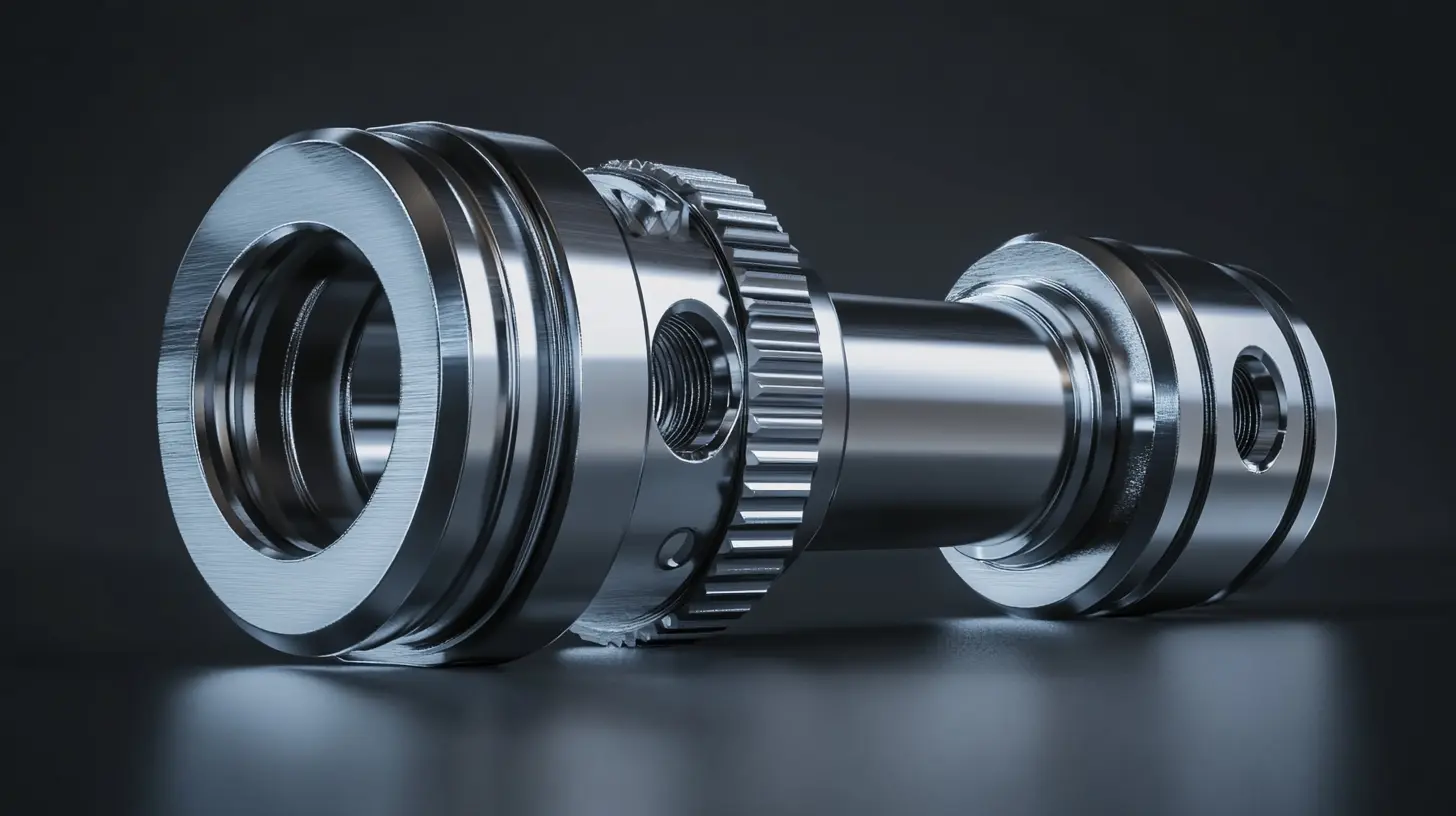

Collet chucks must be used appropriately to meet the requirements of global sourcing in precision and efficiency, which is to be applied in machining processes. Cost saving extends to both cost and the eventual quality of the end delivery, and the collet chucks cater both to engineering requirements as well as overhead costs. Used for holding a piece of cylindrical work in a true and even manner-the collet chuck is a universally applied work-holding device from automobile to aerospace industries, because as global markets are demanding higher quality, the turnaround time is also shortening. Therefore, the greater importance of selecting an accurate collet chuck becomes really important. While ordering collet chucks, one should consider various certifications relevant to their performance and reliability. Certifications give assurance of meeting industry standards in terms of accuracy, safety, and durability. The latest position includes the extended nose Swiss collet, which has sophisticated features to allow access in pinhole locations and better grip. Hence, knowledge of such certifications will enable the manufacturers to take precise decisions that should eventually contribute to productivity and reduced downtime in operations.

In terms of the collet chuck industry, ensuring key credentials relating to standard certifications that ensure product reliability and safety. These include essential certifications such as ISO 9001, aimed at quality management systems; ISO/TS 16949 - for the automotive industry; as well as RoHS and CE mark, which actually refer to environment and safety regulations compliance that greatly assure customers with reliability for the products.

Now that global sourcing strategies are changing, understanding the new certification trends will help navigate such nations toward effective international procurement. The increasing attention of companies today on digitalization and models that sell directly to buyers makes the study of the various standards more than just a form of trust-building exercise with their partners; it also enhances operational efficiencies. Being such a competitive area now, these major certifications will give an edge to companies that not only comply with them but take them as priorities toward obtaining leadership in the collet chuck market.

In today's world of competition in manufacturing, ISO certifications are essential to supporting quality assurance and industry benchmarking. Standard processes not only help companies ensure compliance but also build credibility with clients and partners. As the global market continues to evolve, the share of certification becomes larger, with industries from metalworking to healthcare advocating and mobilizing for regulated qualifications.

Besides it all, recent instances of grooming demonstrate the continuing increase in areas demanding specialized certifications, for instance, in executive coaching and AI. As industry-new technologies and methodologies are adopted, certifications stand as a measure of competence and professionalism. This goes a long way in workforce development and continuously improves upon product and service delivery for the end consumer.

When selecting collet chucks, understanding ANSI standards is very important, as these certifications ensure product quality and compatibility. The American National Standards Institute is the framework standard-setting group for the manufacturing equipment industry to which this group is associated, and the ANSI role goes a long way toward harmonization across sectors. ANSI also helps buyers to decide wisely when sourcing collet chucks so that they pick parts that meet given performance criteria.

In addition, the relevance of ANSI certification is not limited to compliance; rather, it guarantees the supplier's credibility, which provides a competitive advantage in the global marketplace. By choosing certified products, companies can reduce sourcing risks and boost operational efficiency. Given the paramount importance of quality and reliability, the ANSI understanding is the very tenet for effective collet chuck sourcing.

The significance of CE marking for firms wishing to acquire access to the European market lies in proving conformity to standards of safety, health, and environmental protection. More than just a certificate, it is an expression of quality and creates consumer confidence, thereby enhancing marketability. CE-marked merchandise find somewhat easier paths through regulatory environments to engage European consumers, who today are ever more mindful of certified products.

Also, certifications' importance transcends the box of mechanical components like collet chucks. Whether in the food industry or for sustainable sourcing, any certifications have had a role in answering questions on consumer preferences and societal concern. For example, responsible sourcing certifications are gaining recognition as evidence of a brand's assertion to ethical conduct and environment-friendly activities. This consumer-driven aspect thereby makes CE marking and similar certifications key to building credibility and promoting trust among the competitors in the European market.

Following international standards like ASME in the name of safety comes with not just efficiency and safety for personnel but also excludes risks in the purview of design, manufacturing, and testing, as it does for collet chucks. Such end products can guarantee stringent safety requirements in being available on competitive markets. ### 2 developing certifications for data security now emphasizes industry standards more than ever before.

Continuous improvement for business thus translates into quality conformance by getting certifications for each sector. It serves to endorse not only credibility in the market but faith in the eyes of clients and stakeholders. Adopting best practices like the ASME standards for collet chucks would put companies at the helm of their fields in such a way that would spur innovation and safety into the future.

Material sourcing has pivotal RoHS compliance for manufacturers focused on sustainability and environmental responsibility. Thus, restrictions on hazardous substances not only help reduce toxic waste but also assure the customer that the products are safe and eco-friendly. Compliance becomes one of the critical considerations for industries using collet chucks since these components will probably directly affect the quality and safety of the manufactured parts.

Emerging trends in collet chuck technologies strongly endorse the use of compliant materials. Advanced systems and designs can be harnessed to enhance productivity and machining capabilities in compliance with RoHS. However, while manufacturers of two-collet chucks and optimized collet design strive for better performance, this must occur within a scenario in which their sourcing practices align with regulatory mandates. This dual focus on efficiency and compliance is key to remaining competitive in the current marketplace.

The progressive regulations on the environment have, without doubt, made a dent in collet chuck manufacturing. Globally, the tightening of laws toward sustainability is making manufacturers to rethink the various processes involved in production. Not only will this shift require that green materials be used, but it will also require that more efficient manufacturing processes be adopted in producing collet chucks. Therefore, compliance with these regulations will be a big priority for corporations that want to maintain their competitive edge in a global playing field.

Thus, with the increasing number of environmentally friendly customers, it follows that much is expected from the producers to prove their credibility in environmental stewardship. Practices that save on waste and energy would ultimately assist these brands gain recognition and brand loyalty from consumers. Focus on sustainable manufacturing makes collet chuck makers in a better position, meeting compliance and the rising concerns of customers regarding environmental factors. Perhaps in the near future, they might be considered as certifications in their own right, given that such a necessity on the part of the industry to fly in the face of a changing world.

The faster changing of requirements regarding collet chuck certification is seen in the field of global manufacturing; this is due to the modernization of technology and industry demand. The advent of new products such as collet chucks with inside air systems and quick change capabilities proves the fact that such systems are expected to improve efficiency and support stringent standards. Most manufacturing professionals want a design that can reduce setup time and lead to precision while using small diameter tools.

In contemporary times, flexibility and accuracy certification have now become a necessity for manufacturers, whose collet chucks are expected to perform various applications, from hard turning to gear grinding, with decreased runout and torque maximization. Proper certification processes are now necessities that shape the future of collet chuck technology in a competitive global market, as companies keep searching for unmatched convenience with their toolholding systems.

Given the rapid technological changes in the manufacturing sector, the importance of collet chuck certifications cannot be stressed enough. Projections for the future suggest that these certifications will become more and more important as companies try to meet higher standards for precision and reliability. With the changing global sourcing arena, companies will have to ensure that their machines meet very stringent certification criteria to be competitive.

The market effect of these certifications is, therefore, poised for increased importance, especially now that the aerospace and the automotive sectors are giving greater focus to quality assurance. With the growing demand for consistency and safety from suppliers, these certified collet chucks will soon become a necessary part of building trust and accountability. This certification consideration will influence not only the sourcing side of things but also extend its tentacles to shape the manufacturing practices of tomorrow all around the globe.

ISO certifications are crucial for ensuring quality assurance, maintaining industry standards, and enhancing a company's credibility with clients and partners.

ISO certifications emphasize standardized processes, which help companies comply with regulations in various industries.

Recent trends show a surge in fields requiring specific certifications, such as executive coaching and AI, as industries adapt to new technologies and methodologies.

CE marking signifies compliance with safety, health, and environmental protection standards, facilitating easier access to the European market and enhancing consumer trust.

Consumers increasingly prioritize certified products, and certifications like CE marking enhance marketability and trust in the products.

Certifications serve as benchmarks for competence and professionalism, aiding in workforce development and fostering a culture of continuous improvement.

Responsible sourcing certifications address consumer preferences and societal concerns, demonstrating a brand's commitment to ethical practices and environmental responsibility.

The significance of certifications is growing in various industries, including metalworking, healthcare, food safety, and sustainable sourcing.

Certifications lead to higher quality products and services, ultimately benefiting end consumers by ensuring greater assurance of quality and compliance.

As the global market evolves, certifications are becoming more crucial as they act as a standard for quality and trust, helping companies stand out in competitive environments.