- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

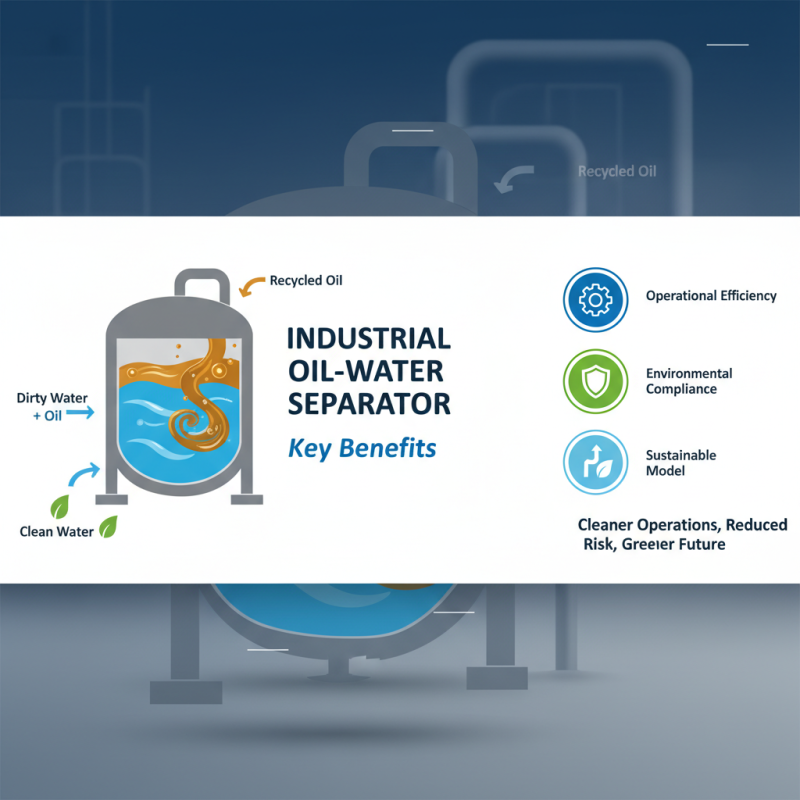

In today’s industrial landscape, the pressing need for sustainable practices and efficient resource management has paved the way for innovative solutions. A pivotal component in this realm is the Industrial Oil Water Separator, a technology designed to effectively separate oil from water, thereby preventing pollution and promoting environmental responsibility. As industry expert Dr. Michael Lawson, a leading authority in wastewater management, aptly puts it, “Utilizing an Industrial Oil Water Separator is not just a regulatory requirement; it’s a commitment to safeguarding our planet’s resources for future generations.”

The benefits of employing an Industrial Oil Water Separator extend far beyond compliance. Businesses that harness this technology can experience significant cost savings through reduced waste disposal fees and improved operational efficiency. Moreover, by minimizing the environmental impact of industrial wastewater, companies position themselves as leaders in sustainable practices, which can, in turn, enhance their brand reputation and attract environmentally-conscious consumers.

As we delve into the top 10 benefits of using an Industrial Oil Water Separator for your business, it becomes evident that this investment not only supports legal obligations but also fosters a culture of responsibility and innovation within the organization. From safeguarding ecosystems to ensuring cleaner production processes, the advantages are numerous, making it an essential tool for any forward-thinking industrial operation.

Industrial oil water separators (OWS) are essential tools for businesses aiming to comply with environmental regulations while maintaining operational efficiency. These separators function by utilizing specific gravity differences between oil and water, enabling the effective separation of oil contaminants from wastewater. According to industry reports, facilities employing such systems can reduce their oil content in wastewater to less than 10 parts per million (ppm), a significant improvement over untreated effluent, which can carry much higher concentrations. This capability is critical for industries such as manufacturing, oil and gas, and automotive, where the risk of oil contamination is prevalent.

The efficiency of industrial oil water separators hinges on their design, which often incorporates multi-stage filtration and flotation processes to optimize separation. For instance, the use of coalescing filters allows smaller oil droplets to combine and rise faster, enhancing overall separation rates. Data from the American Petroleum Institute indicates that utilizing a properly sized and maintained oil water separator can lead to up to a 90% reduction in oil content, translating to substantial savings in disposal costs and potential fines due to non-compliance with environmental standards. Furthermore, advanced separators equipped with sensors and automated controls can provide real-time monitoring, ensuring that businesses can manage their wastewater effectively and adhere to ever-evolving regulatory requirements.

Industrial oil water separators play a crucial role in helping industries achieve environmental compliance, especially in sectors such as manufacturing, automotive, and oil and gas. According to a report by the Environmental Protection Agency (EPA), improper disposal of oil-contaminated water can lead to severe environmental damage and hefty fines for businesses. By efficiently separating oil from wastewater, separators reduce the risk of water pollution, thus ensuring that companies meet regulatory standards and maintain a good reputation.

The use of oil water separators also enhances sustainability efforts. A study by the International Institute of Sustainability found that industries employing these systems can reduce their water usage by up to 50% since treated water can often be reused in operations. Furthermore, businesses that follow environmentally friendly practices not only attract eco-conscious consumers but can also benefit from tax incentives and grants designed to support sustainable initiatives. The implementation of oil water separators signifies a commitment to protecting natural resources, paving the way for long-term operational advantages and compliance with environmental laws.

Implementing an industrial oil water separator can significantly reduce operating costs by optimizing waste management practices within a business. These separators effectively remove oil and other contaminants from wastewater, allowing for cleaner discharge or potential recycling of water. By minimizing the volume of waste that is sent to treatment facilities, companies can lower their disposal fees and avoid hefty penalties associated with non-compliance in waste management regulations. Additionally, reducing the burden of sludge handling and treatment not only saves money but also conserves valuable resources.

Beyond immediate cost savings, using an oil water separator contributes to long-term financial benefits. By promoting a healthier and more sustainable operations strategy, businesses can enhance their reputation and attract environmentally conscious clients and partners. This upgraded approach can lead to new opportunities for cost-sharing programs and incentives that many local governments offer for businesses that implement green technologies. Moreover, as industries face increasing scrutiny regarding environmental impacts, investing in waste management efficiency positions a company favorably against competitors who may not prioritize such practices. Overall, integrating an industrial oil water separator is a strategic move toward sustainable financial health for businesses.

Implementing an industrial oil water separator can significantly enhance operational efficiency within various sectors, particularly those dealing with substantial water and oil discharge. These separators utilize advanced technology to separate oil from water, ensuring that businesses can dispose of waste responsibly while complying with environmental regulations. This not only minimizes legal risks but also helps companies maintain a sustainable operational model, which is increasingly important in today’s environmentally conscious market.

**Tips:** When selecting a separator, consider factors such as the volume of wastewater generated and the type of oil present. Tailoring your separator to your specific needs can optimize performance and reduce maintenance costs. Regularly scheduled maintenance and inspections are also crucial; they can prevent unexpected downtime and prolong the lifespan of your equipment.

Moreover, utilizing a high-efficiency oil water separator contributes to enhanced productivity. By reducing the time and resources spent on waste management, businesses can redirect their focus to core operations. This strategic shift not only boosts overall productivity but also results in cost savings, allowing companies to invest in other areas of growth and innovation.

**Tips:** Training employees on the proper use and maintenance of the separator can ensure its longevity and effectiveness. A well-informed team can promptly address any issues, further contributing to seamless operations.

In industrial settings, the management of oil and water mixtures is critical not only for environmental compliance but also for enhancing workplace safety. Oil water separators play a pivotal role in minimizing risk by effectively removing harmful substances from wastewater before it is discharged. This preventive measure significantly lowers the likelihood of spills and contamination that could pose significant hazards to both employees and the surrounding environment.

By investing in an industrial oil water separator, businesses can implement a proactive approach to risk management. The separation process helps prevent slip-and-fall accidents caused by oil spills, which are common in industrial facilities. Additionally, when contaminants are efficiently removed from wastewater, the potential for equipment damage, downtime, and related costs decreases. This proactive maintenance not only safeguards personnel but also enhances operational efficiency, fostering a safer and more productive workplace.

| Benefit | Description | Impact on Business |

|---|---|---|

| Enhanced Compliance | Meets environmental regulations for discharge. | Reduced risk of fines and legal issues. |

| Improved Safety | Limits oil spills and related hazards in the workplace. | Decreased accidents and injuries. |

| Cost Savings | Reduces costs associated with waste disposal. | Lower operational expenses. |

| Efficiency in Operations | Streamlined processes for treating wastewater. | Greater productivity and less downtime. |

| Protection of Equipment | Reduces corrosion and maintenance needs. | Increased lifespan of machinery. |

| Environmental Responsibility | Shows commitment to sustainable practices. | Enhances brand reputation. |

| Customizable Solutions | Options available to meet specific needs. | Tailored approaches that fit business requirements. |

| Reduction in Waste Volume | Decreases the amount of waste needing disposal. | Lower waste management fees. |

| Risk Management | Minimizes liabilities linked to oil spills. | Less legal exposure and financial risk. |

| Improved Community Relations | Positively impacts local environment. | Builds goodwill among community stakeholders. |