- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

When it comes to power tools and equipment, having a reliable source of compressed air is essential for various applications, from heavy-duty industrial tasks to simple home projects. A Gas Air Compressor stands out as a versatile solution, capable of delivering high performance even in remote locations where electricity may not be readily available. These compressors are particularly favored by contractors, automotive professionals, and DIY enthusiasts for their mobility and ability to sustain pressure over extended periods.

Choosing the right gas air compressor can significantly enhance your productivity and efficiency. With numerous models and specifications available on the market, it can be challenging to identify the top performers that best suit your needs. This guide will explore the top 10 gas air compressors, focusing on features such as airflow delivery, tank capacity, and overall durability, ensuring you make an informed decision. By understanding the key attributes of each model, you'll be better equipped to select a gas air compressor that will not only meet your requirements but also provide reliable performance for years to come.

Gas air compressors are essential tools in various industries, providing a portable and reliable source of compressed air. Unlike electric compressors, gas-powered models offer the advantage of mobility, allowing users to operate them in remote locations or areas without access to electricity. This characteristic makes them particularly valuable in construction, landscaping, and automotive repair applications, where power sources may not be readily available. Their robust performance ensures they can deliver high-pressure air efficiently, catering to a wide range of tools and equipment.

In addition to their mobility, gas air compressors are often favored for heavy-duty tasks that require sustained energy output. They can handle longer run times without overheating, making them ideal for extensive projects. Whether powering pneumatic nail guns on a construction site or providing air for spray painting and sandblasting, these compressors are designed to meet demanding performance expectations. Furthermore, their durability and resistance to environmental conditions enhance their utility in outdoor settings, solidifying their role as indispensable equipment across multiple sectors.

This chart presents a comparison of the top 10 gas air compressors based on their tank capacity (in gallons) and maximum pressure (in PSI). The data illustrates the efficiency and performance features of these compressors for a variety of applications.

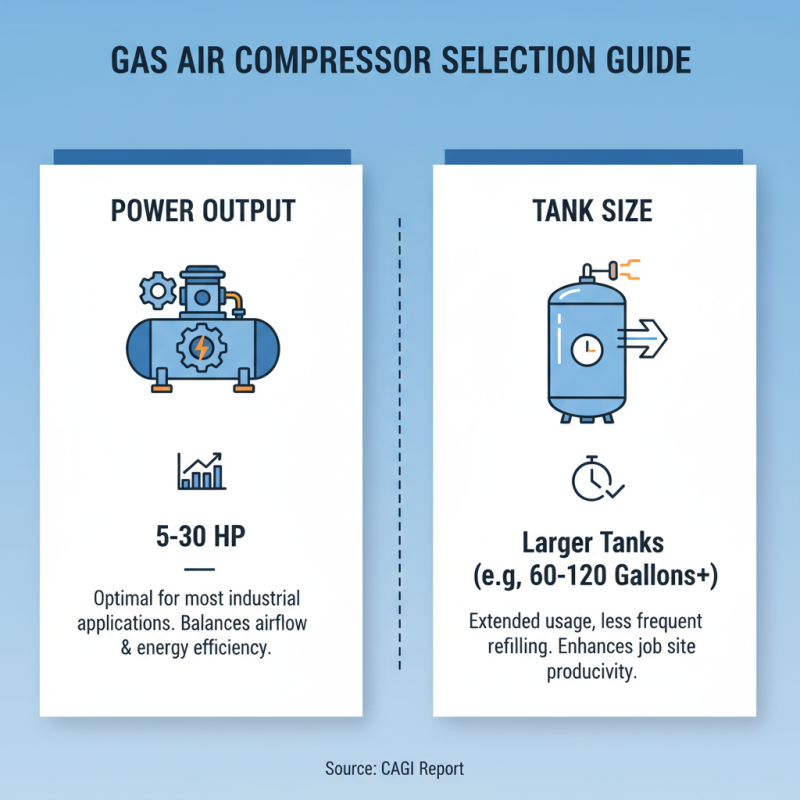

When selecting a gas air compressor, several key features must be considered to ensure efficient and reliable performance. First and foremost, the power output is critical. According to a report by the Compressed Air and Gas Institute (CAGI), compressors with a horsepower rating between 5 to 30 are optimal for most industrial applications, providing necessary airflow while maintaining energy efficiency. Moreover, the tank size is another essential factor; larger tanks can store more compressed air, allowing for extended usage without frequent refilling, thus enhancing productivity on job sites.

Portability and weight are also significant considerations, especially for those needing mobility in their work environment. Data from the U.S. Department of Energy indicates that lighter models can improve performance and ease of use in various settings, including construction sites and agricultural applications. Furthermore, the type of fuel efficiency should not be overlooked. According to industry standards, gas compressors with low fuel consumption ratings can save users hundreds of dollars over time, contributing to cost-effective operations. By focusing on these key features — power output, tank size, portability, and fuel efficiency — users can make informed decisions that align with their specific requirements and industry demands.

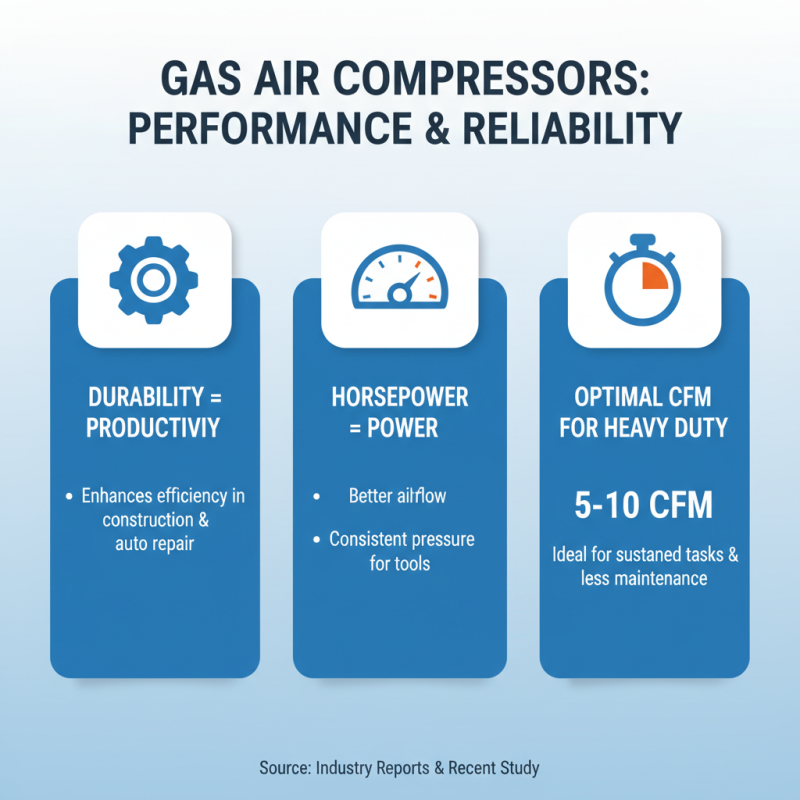

When considering the most effective gas air compressors, performance and reliability ratings are paramount. According to industry reports, durable gas air compressors can significantly enhance productivity in various applications, from construction sites to automotive repair shops. A recent study highlighted that models with higher horsepower ratings often deliver better airflow and pressure consistency, which are critical for pneumatic tools and equipment. Notably, compressors operating at 5 to 10 CFM (cubic feet per minute) are ideal for heavy-duty tasks, ensuring that users maintain efficiency without frequent interruptions for maintenance.

Reliability is another crucial factor when selecting a gas air compressor. Research indicates that machines equipped with robust engines and enhanced cooling systems experience less downtime, thus maximizing their operational longevity. For instance, units featuring cast-iron cylinders and oil-lubricated pumps have been shown to outperform their counterparts in terms of durability, often extending service life by over 40%. Furthermore, user reports suggest that regular maintenance, such as checking fuel filters and oil levels, can significantly improve performance ratings, ensuring that contractors and DIY enthusiasts alike can depend on their equipment for consistent reliability over time.

When it comes to gas air compressors, choosing a reliable and efficient model is crucial for various industrial applications. Comparative analyses of popular gas air compressor brands reveal some key data. According to industry statistics, gas-powered compressors tend to deliver greater mobility and freedom compared to electric compressors. They are typically preferred for heavy-duty tasks due to their ability to operate in remote locations without the need for electrical outlets. Additionally, a recent report indicated that gas compressors often provide a higher air output per cycle, making them a suitable choice for demanding applications.

In evaluating efficiency, it's important to consider the compressor's fuel consumption as well. Studies have shown that modern gas air compressors can achieve up to 20% greater fuel efficiency than their older counterparts. This aspect is critical for businesses looking to reduce operational costs while still acquiring the power needed for their tasks. When selecting a gas air compressor, assess options that feature advanced engine technology and innovative compressor designs for optimal performance.

**Tips:** Look for compressors with a dual-stage compression system; this design enhances pressure output and efficiency. Regular maintenance is also key—keeping the air filters clean can prevent performance drops and extend the equipment’s lifespan. Always review performance specifications and efficiency ratings, as these metrics can significantly impact long-term costs.

| Model | Horsepower | Tank Size (Gallons) | Max PSI | Weight (lbs) | Average Price ($) |

|---|---|---|---|---|---|

| Model A | 5 HP | 20 | 150 | 180 | 700 |

| Model B | 6 HP | 30 | 175 | 220 | 900 |

| Model C | 7 HP | 25 | 200 | 190 | 1,050 |

| Model D | 8 HP | 50 | 225 | 250 | 1,200 |

| Model E | 3 HP | 15 | 120 | 150 | 600 |

| Model F | 10 HP | 60 | 250 | 370 | 1,500 |

| Model G | 4 HP | 20 | 130 | 160 | 750 |

| Model H | 9 HP | 40 | 240 | 300 | 1,400 |

| Model I | 2 HP | 10 | 100 | 120 | 400 |

| Model J | 11 HP | 75 | 300 | 400 | 1,800 |

Maintaining gas air compressors is critical for ensuring their long-lasting performance and reliability. Regular maintenance not only extends the lifespan of the compressor but also enhances its efficiency. According to industry reports, properly maintained compressors can operate up to 30% more efficiently compared to poorly maintained units. Key maintenance tasks include routine inspections, oil changes, and filter replacements. Experts recommend checking the oil level and quality every 500 operating hours, as contaminated or insufficient oil can lead to severe mechanical failures.

Additionally, ensuring that the air intake filters are clean is essential for maintaining optimal airflow and preventing dust buildup, which can lead to overheating. Regularly inspecting hoses and fittings for leaks can save a significant amount of energy; leaks in compressed air systems can waste up to 30% of the total energy consumption according to the U.S. Department of Energy. Implementing scheduled maintenance, including lubricating moving parts and checking pressure gauges, fosters an environment where the compressor runs efficiently and reliably, significantly reducing the risk of unexpected breakdowns and costly repairs.