- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

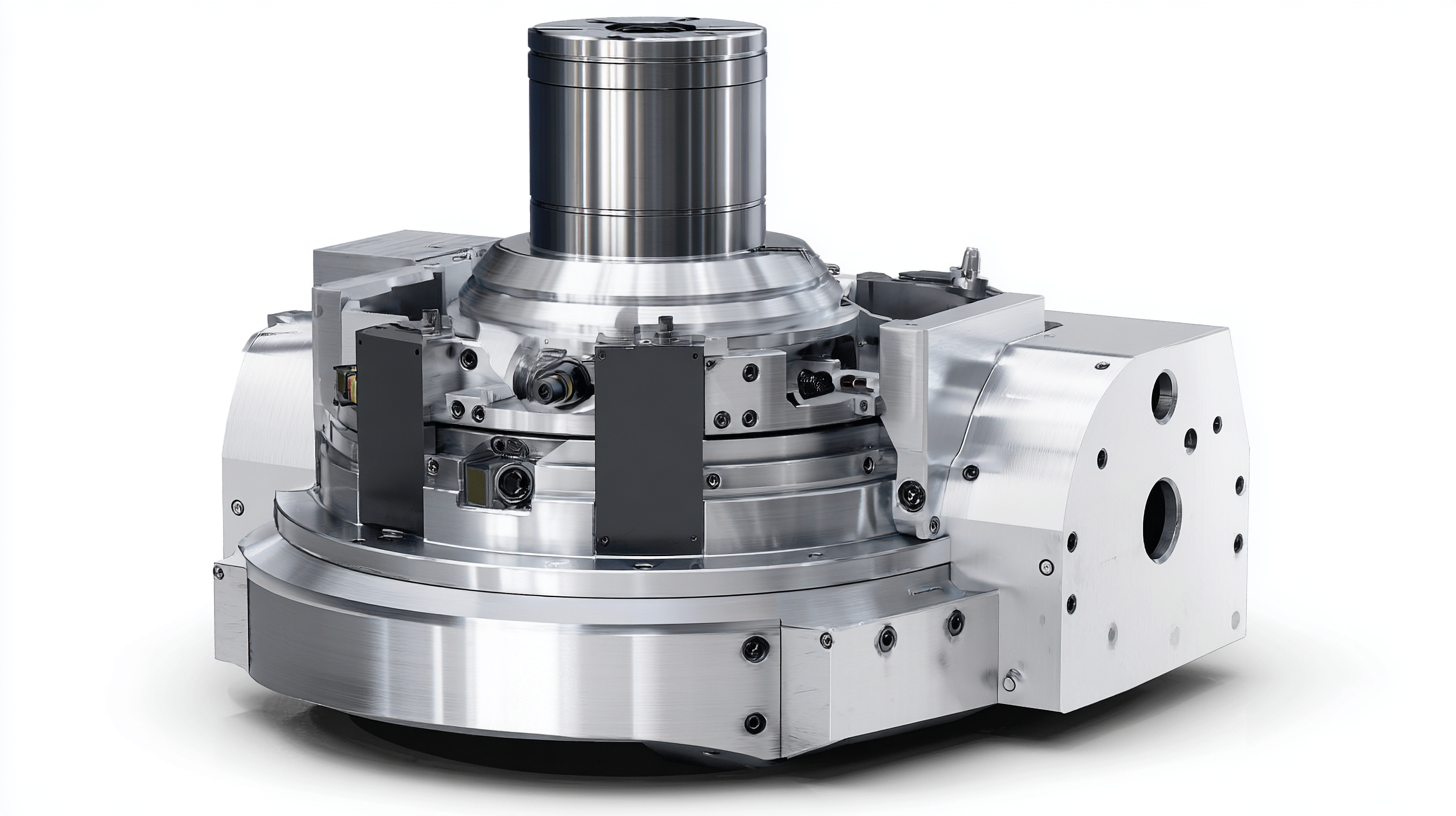

In the realm of precision machining, the efficiency and versatility of tooling are paramount. The Universal Milling Head has emerged as a critical component in this industry, facilitating enhanced performance and adaptability across a spectrum of machining tasks. According to a recent report by Research and Markets, the global CNC milling machine market is projected to reach $100 billion by 2025, highlighting the growing demand for technologically advanced machining solutions, such as Universal Milling Heads, that can improve production capabilities and reduce lead times.

The Universal Milling Head allows for complex operations such as horizontal, vertical, and angular milling, providing manufacturers with the flexibility needed to tackle intricate designs and diverse materials. As companies strive to keep pace with increasing market demands while maintaining high-quality standards, investing in advanced milling technologies is becoming essential. For instance, a study by the American Society of Mechanical Engineers (ASME) indicates that milling operations can account for up to 30% of the total machining time in manufacturing processes, emphasizing the need for efficient milling solutions that can optimize workflow and productivity.

As we delve into the top 10 Universal Milling Heads of 2023, it is crucial to recognize their significant role in enhancing machining efficiency and driving innovation in the manufacturing sector. By examining the latest advancements and features, manufacturers can make informed decisions when selecting the best milling solutions to meet their operational needs.

When selecting a universal milling head in 2023, it is essential to consider several key features that will enhance machining efficiency. First and foremost, the rigidity of the milling head plays a pivotal role in the overall performance. A stronger head can reduce vibrations during operation, which not only improves precision but also extends tool life. Research indicates that milling heads with high rigidity can increase productivity by up to 20%, highlighting their importance in professional machining setups.

Another critical feature to look for is the versatility of the milling head. Modern universal milling heads offer a range of adjustability that accommodates various materials and machining operations. This adaptability allows for efficient transitions between tasks, which is particularly beneficial in environments with diverse production needs. Data shows that facilities employing versatile milling heads can reduce setup times by approximately 30%, significantly boosting overall efficiency.

Additionally, the integration of advanced CNC technologies in milling heads is crucial for enhancing productivity. Features like real-time monitoring and data integration can lead to more informed decision-making and better maintenance practices. Incorporating these technologies can result in a decrease in downtime by up to 15%, making it easier for businesses to meet tight production schedules. Thus, choosing the right universal milling head with these features is vital for maintaining a competitive edge in the machining industry.

When it comes to selecting the best universal milling head for your machining projects, a comparative analysis of the top products on the market is crucial. In 2023, efficiency and versatility are key factors that manufacturers are focusing on. Leading milling heads are designed to enhance stability, reduce vibration, and provide a wider range of movement, allowing operators to achieve precise results on various materials. Features like automatic tool changers and built-in coolant systems further improve machining efficiency, making them indispensable for modern workshops.

Tips: Before making a purchase, consider the compatibility of the milling head with your existing machinery. Assessing the motor capacity and the range of attachments available can significantly influence your overall productivity. Additionally, always look for heads with adjustable feed rates to cater to diverse cutting tasks.

Investing in a quality universal milling head not only improves output quality but also reduces downtime. Many of this year's top models offer digital controls for easier operation and monitoring. When evaluating options, prioritize heads that also provide detailed performance data and user feedback, ensuring that you choose a reliable and effective tool for your machining needs.

| Model | Weight (kg) | Power (kW) | Speed Range (RPM) | Max Tool Diameter (mm) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 25 | 5.5 | 100 - 2000 | 80 | 1200 |

| Model B | 30 | 7.5 | 150 - 2500 | 90 | 1400 |

| Model C | 22 | 6.0 | 120 - 1800 | 85 | 1100 |

| Model D | 28 | 5.0 | 140 - 2200 | 75 | 1300 |

| Model E | 26 | 4.5 | 130 - 2000 | 80 | 1000 |

| Model F | 32 | 8.0 | 160 - 2400 | 100 | 1500 |

| Model G | 24 | 5.2 | 110 - 1900 | 70 | 1150 |

| Model H | 29 | 6.8 | 125 - 2050 | 95 | 1350 |

| Model I | 31 | 7.2 | 100 - 2100 | 90 | 1450 |

| Model J | 27 | 4.3 | 110 - 1850 | 76 | 980 |

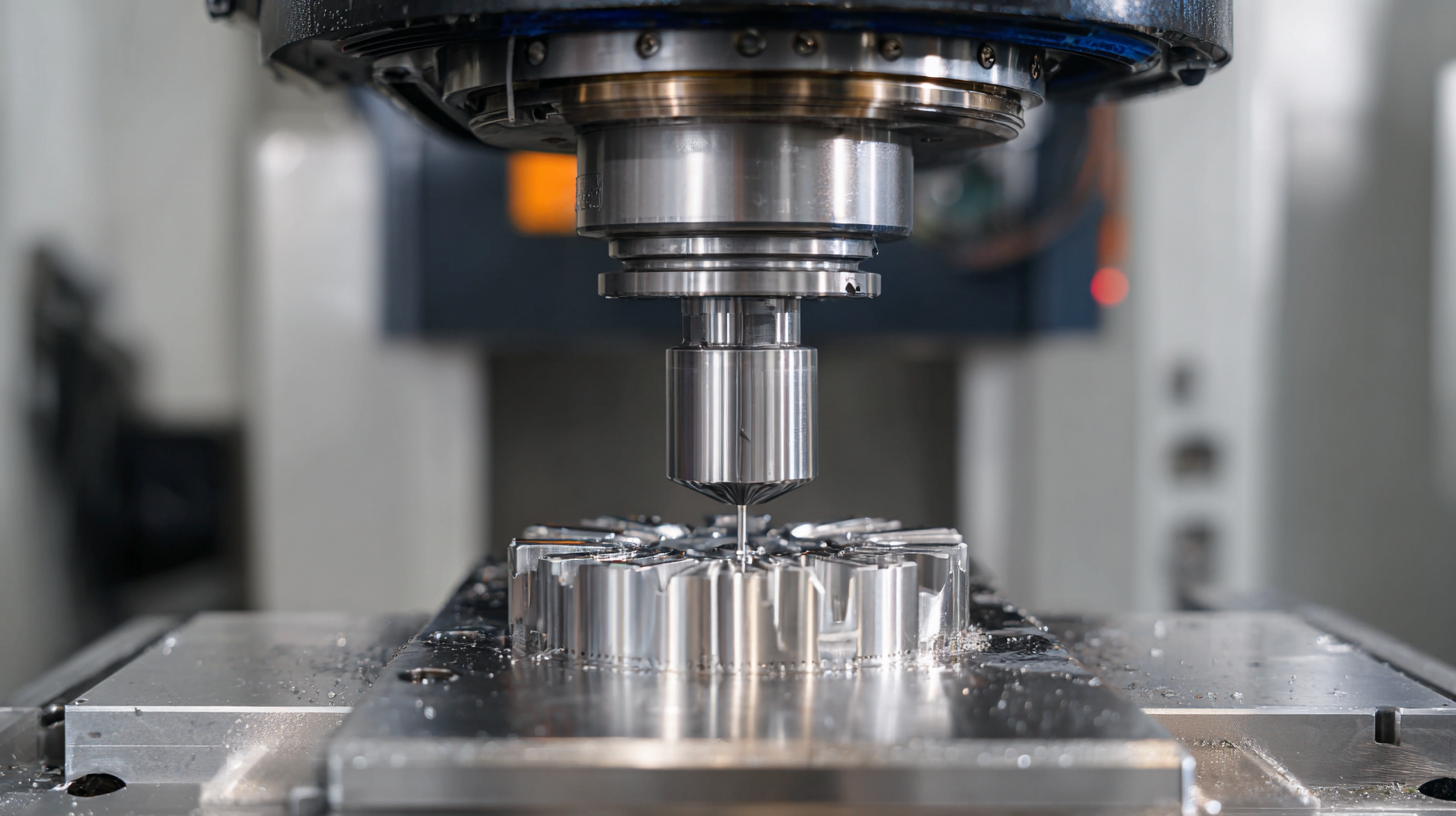

Universal milling heads are essential tools for improving machining efficiency and optimizing manufacturing workflows. By enabling multiple cutting angles and versatile operations, these heads allow operators to complete complex tasks without the need for frequent tool changes. According to a report by Grand View Research, the global CNC machining market is projected to grow at a CAGR of 6.5% from 2021 to 2028, primarily driven by the increasing demand for precision engineering and automation in manufacturing. This trend highlights the importance of incorporating advanced tools like universal milling heads to maintain a competitive edge.

Universal milling heads are essential tools for improving machining efficiency and optimizing manufacturing workflows. By enabling multiple cutting angles and versatile operations, these heads allow operators to complete complex tasks without the need for frequent tool changes. According to a report by Grand View Research, the global CNC machining market is projected to grow at a CAGR of 6.5% from 2021 to 2028, primarily driven by the increasing demand for precision engineering and automation in manufacturing. This trend highlights the importance of incorporating advanced tools like universal milling heads to maintain a competitive edge.

Moreover, the use of universal milling heads can significantly reduce cycle times and improve product quality. A study by Deloitte reveals that manufacturers implementing advanced machining technologies, including universal tools, have observed productivity gains of up to 20%. This efficiency boost is attributed to the enhanced flexibility these tools provide, allowing for quicker adaptations to changes in design or production requirements. By investing in high-quality universal milling heads, manufacturers can not only streamline their workflows but also achieve higher output rates while maintaining precision standards necessary for today's market demands.

To maximize the lifespan of your universal milling heads, regular maintenance is essential. One of the first steps includes keeping the milling heads clean. Debris and chips can interfere with the performance and precision of the machine, so ensure they are removed after each use. Additionally, inspecting the heads for wear and damage can help identify potential issues before they become serious problems, allowing for timely repairs or replacements.

Lubrication also plays a crucial role in maintaining your milling heads. Using the appropriate lubricant reduces friction and wear on the parts, thus extending their operational life. It is advisable to follow the manufacturer's guidelines regarding lubricant type and application frequency. Furthermore, regularly checking alignment and calibration ensures that the milling heads operate at peak efficiency, contributing to improved machining processes. By implementing these maintenance tips, you can enhance the durability and performance of your milling heads, leading to greater productivity in your machining operations.

In 2023, the landscape of universal milling technology is undergoing significant transformations aimed at enhancing machining efficiency. One of the most notable trends is the integration of advanced automation and artificial intelligence. These technologies enable milling heads to optimize operational parameters in real-time, reducing manual intervention and increasing precision. As manufacturers seek to enhance productivity, the adoption of smart milling heads that can adjust feeds and speeds autonomously will become increasingly prevalent.

Another emerging trend is the focus on sustainability within the milling process. Manufacturers are developing eco-friendly materials and energy-efficient designs that aim to minimize waste and reduce the carbon footprint of machining operations. Additionally, innovations such as enhanced cooling systems and chip management solutions are contributing to longer tool life and improved performance. As the industry moves towards greener practices, the evolution of universal milling technology will play a crucial role in meeting new environmental standards while ensuring high productivity levels.