- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

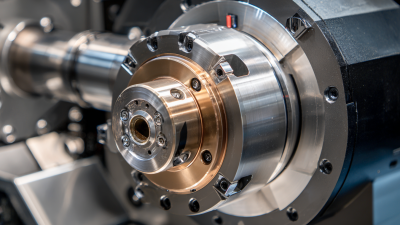

In the realm of modern machining, the Driven Angle Head stands out as a revolutionary tool that significantly enhances operational efficiency and versatility. By allowing for angular adjustments during machining processes, this innovative device enables manufacturers to achieve precise angles and cut intricate shapes without the need for multiple setups. The versatility of the Driven Angle Head not only streamlines production workflows but also reduces machining time and costs, making it an invaluable asset in today's competitive manufacturing landscape.

This blog will delve into the functionality of the Driven Angle Head, exploring its design features, applications, and the advantages it offers in enhancing precision and productivity. Whether you're a seasoned machinist or new to the field, understanding the capabilities of this tool can dramatically elevate your machining operations.

The driven angle head has become a crucial component in modern machining, significantly enhancing machining flexibility across various applications. By allowing for multi-axis machining in a single setup, the driven angle head provides manufacturers the ability to achieve complex geometries that would otherwise require multiple tools and setups. This versatility reduces production time and minimizes the chances of error, leading to higher efficiency and lower operational costs.

Moreover, the adaptability of the driven angle head enables it to accommodate a wide range of tools and attachments. This feature allows machinists to switch between different operations—such as drilling, milling, and tapping—without the need for extensive reconfiguration. With precise alignment and angular adjustments, the driven angle head facilitates detailed work that meets stringent specifications. As industries continue to demand more complex components, the role of the driven angle head in providing flexible, efficient machining solutions will undoubtedly become more prominent, positioning manufacturers to meet the ever-evolving market demands.

| Feature | Benefits | Application Areas | Technical Specifications |

|---|---|---|---|

| Multi-axis Machining | Increased flexibility and complex shape capabilities | Aerospace, Automotive, Medical devices | Able to operate at angles up to 90 degrees |

| Enhanced Tool Life | Reduction in wear due to optimal cutting angles | Heavy machinery parts, Custom tooling | Precision angles adjustable within 1 degree |

| Space Efficiency | Compact design allows for more workspace | Tool and Die, Mold Manufacturing | Designed to work with machines having limited space |

| Quick Tool Change | Minimizes downtime and enhances productivity | Batch production, Prototyping | Compatible with various standard tool holders |

Driven angle heads have become crucial components in modern machining, enabling increased

flexibility and

efficiency in operations. These innovative tools allow for the machining of complex geometries without the need for multiple setups, ultimately reducing production time and improving accuracy. A study by the American Machining Association reports that utilizing driven angle heads can enhance productivity by up to 30%, making them an integral part of advanced manufacturing processes.

Key components of driven angle heads typically include a motorized spindle, an indexing mechanism, and precision bearings, which together allow for smooth operation across various angles. The design features of these tools are meticulously engineered to withstand the rigors of high-speed machining. For instance, the use of high-strength materials reduces vibrations and enhances stability during operation. According to a recent report from the International Journal of Advanced Manufacturing Technology, the advancement in design technologies has resulted in angle heads capable of achieving torque ratings up to 50% higher than their predecessors, further optimizing machining capabilities in industries such as aerospace and automotive.

Driven angle heads have become essential components in modern manufacturing, significantly enhancing machining capabilities by allowing for multi-axis operations. These innovative tools enable machines to perform complex cuts at various angles, which is particularly beneficial in industries that require intricate designs, such as aerospace and automotive manufacturing. By providing flexibility to reach difficult geometries, driven angle heads help in achieving high precision and reducing setup times, thereby boosting overall productivity.

In addition to their versatility, driven angle heads are widely used in specific applications such as contour machining, drilling, and tapping on complex workpieces. They facilitate operations on components that would otherwise require multiple setups or specialized fixtures. Moreover, the integration of driven angle heads with CNC machines allows manufacturers to optimize their workflow, minimizing downtime and waste while ensuring consistent quality. As companies continue to seek ways to improve efficiency and reduce costs, the adoption of driven angle heads is likely to expand, setting the stage for further innovations in the realm of modern manufacturing.

This chart illustrates the percentage of various applications of driven angle heads in modern machining processes.

In modern machining, the incorporation of driven angle heads significantly enhances operational efficiency and precision. These innovative tools allow for the execution of complex machining tasks at various angles, which traditionally required multiple setups and extended machining times. By enabling multi-directional cutting, driven angle heads streamline the machining process, reducing setup times and enhancing overall productivity. This flexibility makes it easier to achieve intricate designs and tight tolerances, positioning manufacturers to meet the increasing demands of contemporary production environments.

Moreover, the benefits of driven angle heads extend beyond efficiency. They also facilitate improved tool life and reduced material waste by optimizing cutting paths. With the ability to tackle various operations, such as drilling, milling, and threading, within a single setup, manufacturers save not only on time but also on tool changes and calibrations. This adaptability makes driven angle heads a valuable investment for businesses aiming to stay competitive in the fast-paced machining sector, ultimately leading to better quality and reduced costs in production.

Driven angle heads represent a significant advancement in modern machining technology, providing enhanced versatility compared to traditional machining tools. Unlike traditional tools that often require multiple setups for different angles and orientations, driven angle heads allow for the machining of complex geometries in a single setup. This substantially reduces production time and increases efficiency, making it an attractive choice for manufacturers looking to optimize their processes.

Additionally, the comparative analysis highlights the flexibility that driven angle heads offer in various applications. While traditional tools may excel in straightforward tasks, they often fall short when faced with intricate designs or tight tolerances. Driven angle heads can accommodate a range of tooling options and adapt to various machining tasks without the need for extensive reconfiguration. This adaptability not only shortens lead times but also minimizes the likelihood of errors associated with multiple setups. As manufacturers strive for greater precision and productivity, driven angle heads are proving to be a vital solution in the competitive machining landscape.