- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

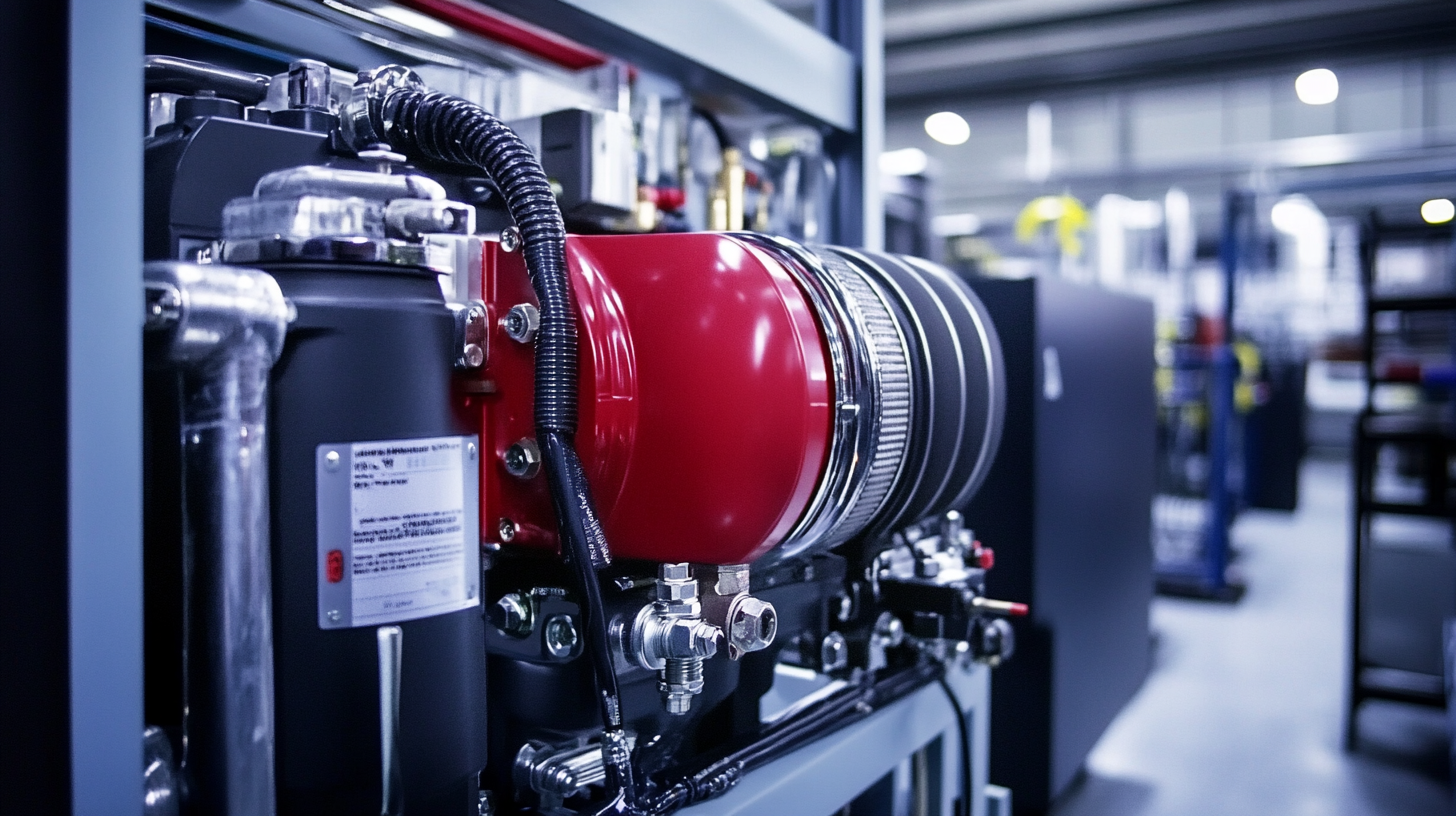

In the realm of industrial and commercial applications, the importance of a reliable Gas Air Compressor cannot be overstated. With a projected market growth rate of 4.5% annually, as highlighted by a recent report from Grand View Research, the demand for efficient and versatile gas-driven compressors is on the rise. These compressors play a critical role in various sectors, including automotive, manufacturing, and construction, where high-pressure air is essential for tools and machinery operation.

Additionally, industry data shows that choosing the right Gas Air Compressor can enhance productivity by up to 30%, making informed decisions based on comprehensive technical specifications pivotal for impactful investments. In this blog, we will explore the key factors of comparison that can help professionals unlock the full potential of these essential devices, ensuring optimal performance and reliability in their operations.

Additionally, industry data shows that choosing the right Gas Air Compressor can enhance productivity by up to 30%, making informed decisions based on comprehensive technical specifications pivotal for impactful investments. In this blog, we will explore the key factors of comparison that can help professionals unlock the full potential of these essential devices, ensuring optimal performance and reliability in their operations.

Gas air compressors have become a vital component in industrial applications, offering numerous advantages that significantly enhance operational efficiency. One of the primary benefits is their portability; gas air compressors are not limited by the availability of electricity, allowing them to operate effectively in remote locations where power supply may be inconsistent or entirely absent. According to a report by Allied Market Research, the global gas air compressor market is expected to reach $8.1 billion by 2027, highlighting the growing reliance on these machines across various sectors, including construction and agriculture.

Moreover, gas air compressors are designed to deliver high output and durability, making them particularly suited for heavy-duty tasks. They can provide higher pressure levels, often exceeding 150 PSI, which is essential for powering pneumatic tools and equipment in demanding environments. Data from the International Air Compressor Association indicates that industries utilizing gas air compressors often report productivity increases of around 30% due to their ability to deliver consistent airflow and faster recovery times. This reliability allows businesses to optimize workflows and minimize downtime, ultimately leading to higher profit margins and enhanced operational performance.

When selecting the best gas air compressor, understanding key technical specifications is essential to ensure optimal performance. One of the most critical specifications is CFM, or cubic feet per minute, which gauges the airflow output of the compressor. A higher CFM rating indicates the compressor can power multiple tools simultaneously or handle larger projects more efficiently. Users should assess their specific applications to determine the appropriate CFM needed for their tasks, ensuring the compressor can meet demand without overworking the machine.

Another important aspect to consider is the tank size, typically measured in gallons. A larger tank provides a reserve of compressed air, allowing for longer run times between refills and reducing the frequency of engine start and stops. This not only enhances efficiency but can also extend the lifespan of the compressor. Additionally, pressure ratings, often measured in PSI (pounds per square inch), dictate the maximum compressive ability of the unit, influencing its effectiveness in a variety of applications, from automotive repair to construction tasks. By carefully evaluating these technical specifications, users can unlock the full potential of the best gas air compressors available on the market.

When comparing gas air compressors to their electric counterparts, several key factors highlight the advantages and disadvantages of each type. Gas air compressors are typically favored for their portability and power. According to a recent report by the American Compressor Society, gas models can deliver higher horsepower ratings, often reaching over 20 HP compared to electric models, which generally peak around 15 HP. This higher output makes gas compressors ideal for heavy-duty applications such as construction sites and agricultural activities where mobility and a robust power supply are critical.

On the other hand, electric air compressors offer distinct benefits in terms of efficiency and operation. Data from the U.S. Department of Energy suggests that electric models can be up to 30% more energy-efficient than gas compressors, leading to lower long-term operational costs. Furthermore, electric compressors have a quieter operation and require less maintenance, making them a preferable option for indoor use or smaller projects. The debate between gas and electric compressors ultimately centers on the specific needs of the user, balancing power requirements and operational practicality against efficiency and ease of use.

To ensure the longevity and efficiency of gas air compressors, implementing best maintenance practices is crucial. According to a report by the Compressed Air and Gas Institute (CAGI), proper maintenance can extend the lifespan of these compressors by up to 30%. Regular inspection and cleaning of filters, along with timely oil changes, are vital practices that maintain optimal performance and reduce the risk of unexpected failures.

Additionally, monitoring operating conditions such as pressure, temperature, and vibration is essential. The International Institute of Ammonia Refrigeration states that consistently checking these parameters can help identify potential issues before they escalate.

Furthermore, adopting a preventative maintenance schedule not only keeps the compressor running efficiently but also minimizes downtime, thereby enhancing overall productivity. For example, companies that engage in proactive strategies often report a reduction in maintenance costs by nearly 25%, reinforcing the importance of routine maintenance in promoting gas air compressor longevity.

Innovations in gas air compressor technology are driving significant advancements in efficiency and performance. As the Global Air Compressor Rental Market is projected to reach USD 8,221.1 million by 2033 at a CAGR of 6.8%, the demand for robust and reliable gas air compressors is on the rise. These compressors are now being developed with advanced features that enhance operational capabilities and reduce energy consumption. The integration of smart technology allows for real-time monitoring and diagnostics, enabling users to optimize performance and minimize downtime.

Additionally, the trend towards sustainability is influencing the design and specification of gas air compressors. Innovations such as improved carbon dioxide capture technologies and the focus on reducing greenhouse gas emissions are shaping the future of this industry. As companies strive to align with environmental goals, adopting gas air compressors equipped with the latest eco-friendly technologies will become a key competitive advantage. This commitment to sustainability not only fosters operational efficiency but also resonates with consumers' growing preference for environmentally responsible products.

| Model | Max Pressure (PSI) | Flow Rate (CFM) | Tank Capacity (Gallons) | Engine Power (HP) | Weight (lbs) | Noise Level (dB) |

|---|---|---|---|---|---|---|

| AC2150 | 150 | 5.3 | 8 | 5.5 | 100 | 78 |

| GC3000 | 175 | 6.5 | 10 | 6.5 | 120 | 82 |

| RH4000 | 200 | 8.0 | 12 | 7.5 | 130 | 85 |

| PG4500 | 220 | 10.0 | 15 | 8.0 | 150 | 88 |