- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

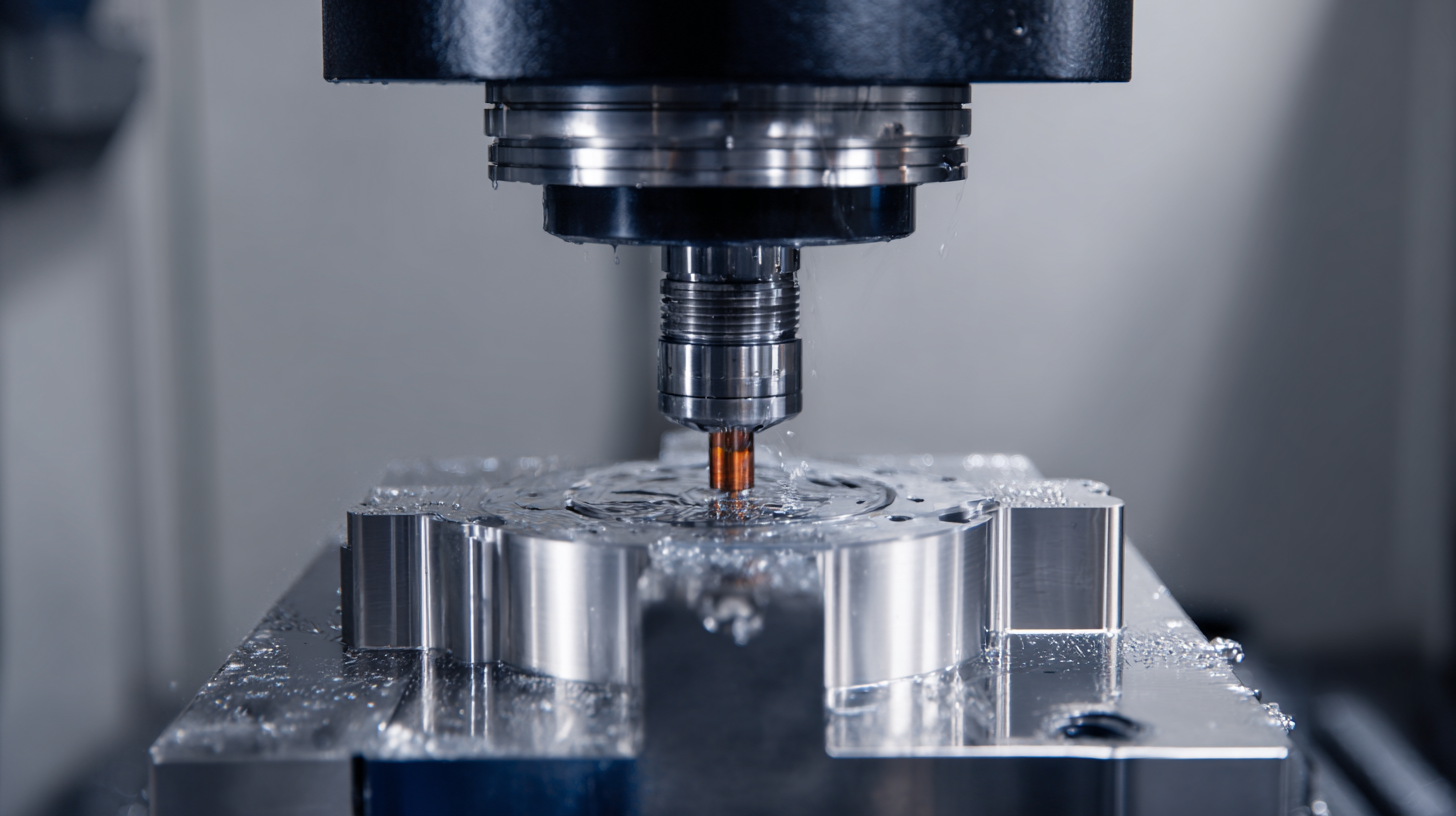

In the realm of precision machining, the Cnc Mill Boring Head plays a pivotal role in enhancing the accuracy and efficiency of your projects. This versatile tool allows for the fine-tuning of hole dimensions and surface finishes, elevating the quality of your machining work. However, to fully harness its capabilities, understanding the operational nuances and setup procedures is crucial. This guide aims to provide a comprehensive overview of how to effectively utilize a Cnc Mill Boring Head, from selecting the right tool and proper configuration to mastering advanced boring techniques. By implementing these strategies, machinists can achieve superior results, ensuring their work meets the highest standards of precision and craftsmanship. Whether you are a seasoned professional or an aspiring machinist, optimizing the use of a Cnc Mill Boring Head will undoubtedly enhance your machining processes and outcomes.

CNC mill boring heads are crucial for achieving heightened precision in machining processes. As noted in a recent industry report by the American Society of Mechanical Engineers (ASME), precise hole making is critical, with nearly 30% of machining errors attributed to inadequate drilling setup. Utilizing a CNC mill boring head effectively addresses this issue, allowing manufacturers to achieve tolerances as tight as ±0.001 inches. This enhanced accuracy not only improves the fit and function of components but also reduces the need for costly rework.

Furthermore, the integration of advanced CNC milling technology has transformed traditional practices. According to a report by the Market Research Future (MRFR), the global CNC milling machine market is projected to reach USD 100 billion by 2025, driven by the increasing demand for precision parts in sectors like aerospace and automotive. High-quality boring heads equipped with robust features offer programmers the flexibility to manage multiple operations within a single setup, significantly reducing cycle times while maintaining quality standards. This convergence of technology and precision machining underscores the importance of incorporating reliable CNC mill boring heads into modern manufacturing workflows.

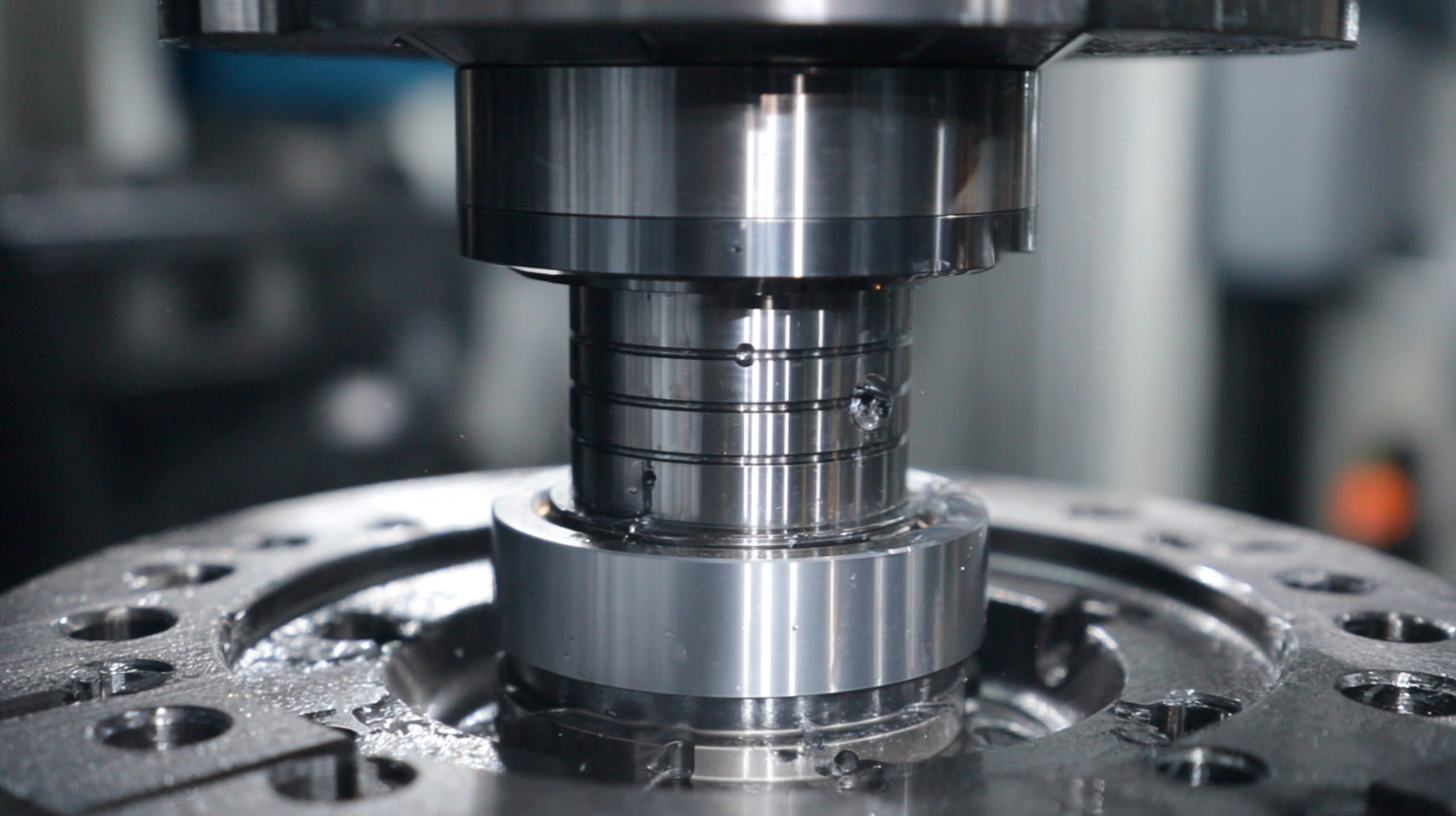

The design of a boring head is essential for enhancing machining accuracy and efficiency in CNC milling operations. A well-engineered boring head provides the stability and rigidity required to minimize vibration during cutting. By incorporating materials with superior strength and precision-engineered components, manufacturers can significantly improve the performance of the boring head. The shape and size of the boring head’s cutting tools also play a crucial role; a design that allows for optimal chip removal and coolant flow can lead to better heat dissipation and increased tool life.

Additionally, the incorporation of advanced features such as micro-adjustments and digital readouts can enhance the ease of use and precision when setting up the machining process. These features allow for finer adjustments, ensuring that the machining tolerances are consistently met. Furthermore, the alignment capabilities provided by a well-designed boring head ensure that holes are drilled accurately, which is particularly important in complex assemblies where misalignment can lead to costly rework. Overall, the design of the boring head is a critical factor in determining the overall effectiveness and accuracy of CNC machining processes.

Achieving exceptional precision in CNC machining often hinges on the use of a boring head, especially when striving for tight tolerances of ±0.001 inches. This level of accuracy is critical in industries such as aerospace, automotive, and medical device manufacturing. CNC boring heads allow for fine adjustments and a more controlled cutting process, enabling operators to achieve superior results when machining complex parts.

To meet and maintain these industry standards, it's essential to ensure proper setup and alignment of the CNC mill boring head. Regular calibration and maintenance play a pivotal role in minimizing errors and enhancing the precision of each machining operation. Furthermore, utilizing high-quality tooling and carefully selecting cutting parameters will yield better surface finishes and extended tool life, giving manufacturers a competitive edge while adhering to stringent tolerance requirements. By integrating these practices, companies can enhance their machining capabilities and deliver components that meet or exceed industry benchmarks.

The integration of CNC mill boring heads into machining processes represents a significant advancement over traditional boring techniques. In conventional methods, operators often rely on manual adjustments, which can lead to inconsistencies and dimensional inaccuracies. In contrast, CNC mill boring heads provide automated control over tool positioning and depth of cut, allowing for enhanced precision. This increased level of control minimizes the risk of human error, enabling manufacturers to achieve tighter tolerances and more uniform results across multiple parts.

Furthermore, the comparative study of boring head techniques highlights their efficiency in setups requiring complex geometries or intricate details. While traditional boring can be time-consuming and labor-intensive, CNC systems streamline the process through programmable operations, reducing cycle times significantly. This tech-driven approach not only accelerates production rates but also allows for easier replication of complex designs, which is often a challenge with manual methods. Ultimately, adopting CNC mill boring heads can lead to substantial improvements in both the quality and efficiency of machining operations.

In the realm of CNC machining, the integration of a CNC mill boring head plays a pivotal role in achieving enhanced precision. One prime example comes from an automotive manufacturer that incorporated this tool to refine their engine block machining process. By employing the boring head, they were able to maintain tighter tolerances, resulting in improved overall performance and reliability of their engines. This case illustrates that precision is not merely an aspiration, but a tangible outcome when the right tools are utilized effectively.

When implementing a CNC mill boring head, here are a few tips to consider: First, ensure proper calibration of the tool before use to avoid any discrepancies during machining. Second, utilize high-quality cutting fluids to aid in chip removal and prolong tool life. Lastly, regular maintenance of both the machine and the boring head is essential to maintain optimal performance and accuracy.

Another notable case involved a tooling company that faced challenges with consistency in their parts. By integrating a CNC mill boring head into their process, they noticed a dramatic reduction in variation. The precise control allowed for uniformity across batch production, showcasing the knack for a well-fitted tool to elevate the standard of quality in machining operations.

| Case Study | Machining Component | Initial Tolerance | Enhanced Tolerance | Precision Improvement (%) | Application Context |

|---|---|---|---|---|---|

| Case Study 1 | Engine Block | ±0.02 mm | ±0.005 mm | 75% | Automotive Manufacturing |

| Case Study 2 | Aerospace Bracket | ±0.03 mm | ±0.007 mm | 76.67% | Aerospace Component Production |

| Case Study 3 | Medical Device Housing | ±0.05 mm | ±0.015 mm | 70% | Medical Equipment Manufacturing |

| Case Study 4 | Gear Component | ±0.01 mm | ±0.002 mm | 80% | Industrial Machinery |

| Case Study 5 | High-Precision Fixture | ±0.04 mm | ±0.010 mm | 75% | Precision Tooling |