0102030405

EK & Index Series Rubber-Flex Collets

EK series Parameters

|

Rubber-flex collets EK68 | |||||||

| type | D mm | L mm | W Unilateral angle | Clamping dia | Smooth | Radial groove | Serrated | |

| EK68S | 68 | 37 | 15 | 6-32 | 6-32 | -- | -- | |

| EK68N | 68 | 37 | 15 | 6-32 | -- | 8-11 | 12-32 | |

| Rubber-flex collets EK93 | ||||||||

| type | D mm | L mm | W Unilateral angle | Clamping dia | Smooth | Radial groove | Serrated | |

| EK93BS | 93 | 50 | 15 | 16-52 | 16-32 | -- | -- | |

| EK93BN | 93 | 50 | 15 | 16-52 | -- | -- | 16-52 | |

| Rubber-flex collets EK110 | ||||||||

| type | D mm | L mm | W Unilateral angle | Clamping dia | Smooth | Radial groove | Serrated | |

| EK110S | 110 | 60 | 15 | 20-66 | 20-66 | -- | -- | |

| EK110N | 110 | 60 | 15 | 20-66 | -- | -- | 20-66 | |

Index series Parameters

|

type | D mm | L mm | W Unilateral angle | Clamping dia | Smooth | Radial groove | Serrated |

| SK221S | 44.3 | 36 | 15 | 4-22 | 4-22 | -- | -- | |

| SK221N | 44.3 | 36 | 15 | 4-22 | -- | 6-12 | 12-25 | |

| >Rubber-flex collets SK9022 | ||||||||

| type | D mm | L mm | W Unilateral angle | Clamping dia | Smooth | Radial groove | Serrated | |

| SK9022S | 44.3 | 37 | 15 | 4-22 | 4-22 | -- | -- | |

| SK9022N | 44.3 | 37 | 15 | 4-22 | -- | 6-12 | 12-25 | |

| > Rubber-flex collets SK321 | ||||||||

| type | D mm | L mm | W Unilateral angle | Clamping dia | Smooth | Radial groove | Serrated | |

| SK321S | 61 | 47 | 15 | 4-32 | 4-22 | -- | -- | |

| SK321N | 61 | 47 | 15 | 4-32 | -- | 6-12 | 12-25 | |

More Details

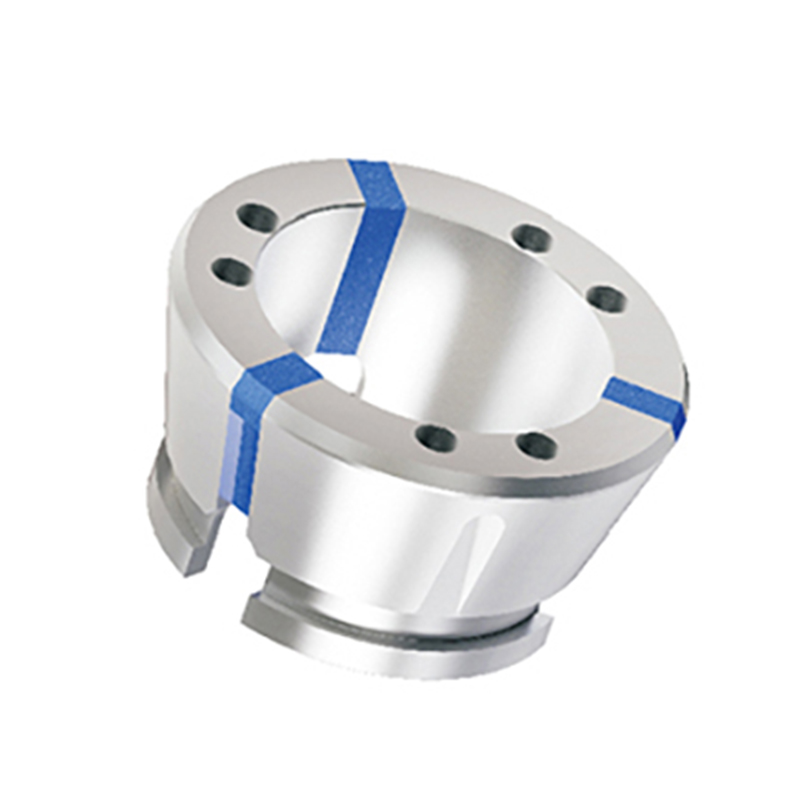

BOD HQC Quick-Change collets can be changed from one size to another in less than 20 seconds. The HQC System requires less draw bar force to adequately grip the bar, greatly reducing the breakage of closing fingers and pins common when the bar varies beyond the range of a standard solid collet or master collet with pads. Eliminating the need to change collets due to normal variations in bar stock, greatly reduces the downtime normally required. Since solid collets and master collets are of a one-piece construction, considerable force is required to flex the leaves of a solid collet and bring the gripping surface in contact with the workpiece OD. Because there are no leaves in the HQC system, additional gripping pressure is directly applied to the workpiece. Higher feed rates and higher spindle speeds are possible. Because of the extra gripping force, tool life increases and parts come off the machine quicker. There is no collet shank. Therefore, the collet segments remain parallel to the stock even when there are variations in the stock size. Parallel clamping minimizes stock “push back” and requires less draw bar force to achieve the same gripping capability as conventional collets. The HQC operator-replaceable slot-seal system eliminates the need to return the collet to the manufacturer to have the seals changed.

Increasing Productivity

Replace your 3-Jaw Power Chuck with the HQC Quick-Change Collet System. The reduction in weight and the unique, efficient design of the HQC System allow you to increase the spindle rpm without any concern for centrifugal forces. Hi-tech cutting tools, along with faster speeds and feeds, can now be used to boost your productivity beyond your previous experience. Chucking forces are higher than jaw chucks and even higher than solid standard and master collets. The interferences associated with jaw chucks are nonexistent with the clean contours of the HQC Quick-Change Collet System.