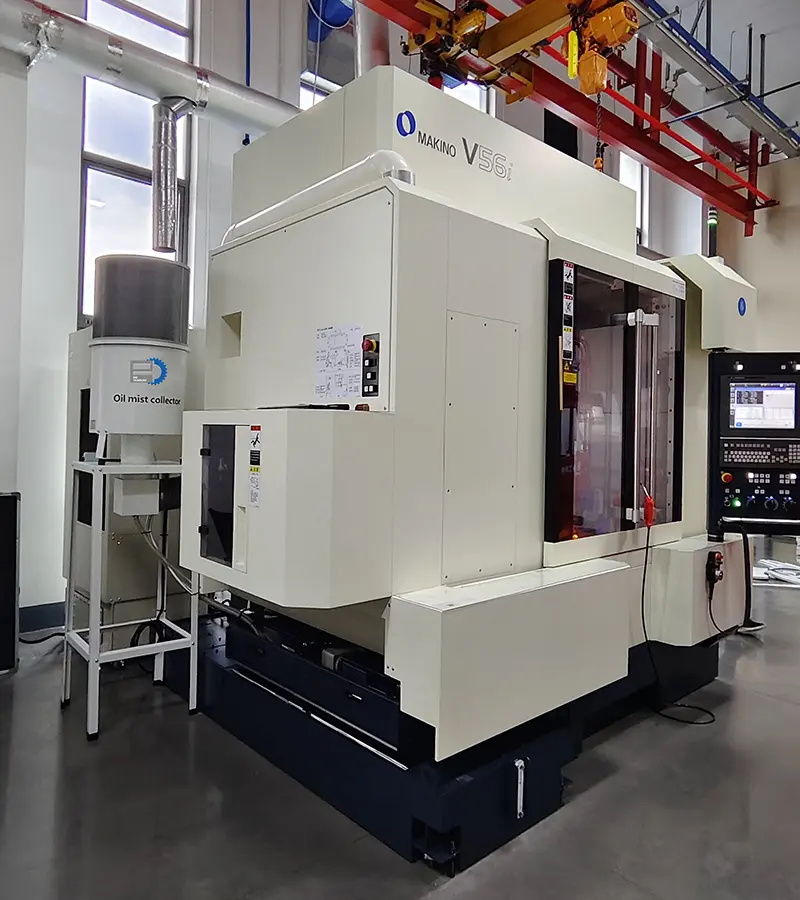

In the modern precision metal processing process, the mist and smoke generated by the rotation of the tool and the metal work-piece, as well as the more complex aerosol particles and solid particles, mostly contain poly-chlorinated biphenyls, which implicitly and seriously damages the work The physical and mental health of the personnel, and the oil mist pollution in the workshop is disgusting and irritating, which seriously affects the production efficiency; secondly, allowing the oil mist to spread in the workshop for a long time will also cause damage to the components in the CNC system and cause losses.

Today, when more and more attention is paid to environmental protection, choosing an environment that can eliminate oil and water fumes and also has fresh air, and then recycle expensive cutting oil to the equipment for reuse, resulting in a comprehensive effect of multiple factors.

The significance of investing in this expenditure equipment cost is actually a deeper reduction and reduction of production costs, and more humanistic care of "people-oriented".