What is an Oil Mist / Collector Air Cleaner?

Oil Mist Air Cleaners is a device used in industrial environments. It mainly filters, removes, and collects pollutants such as oil mist, water mist, dust and smoke generated during mechanical processing that is harmful to the human body and machines.

The industrial oil mist air cleaner can effectively control air pollution and is essential for maintaining a safe, clean, and efficient workspace, especially in industries that involve heavy machinery, manufacturing, and processing.

Applications

- Lathes and Turning

- Milling

- Grinding

- Blade Sharpening

- Drilling

- Special Purpose

Oil Mist Collector Market

Oil Mist Collector Market Scale 2024-2028

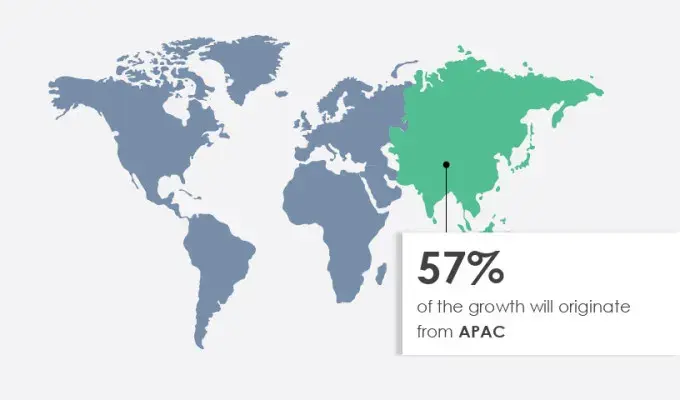

The Oil Mist Collector market size is expected to reach 5.11% during 2023-2028, increasing by a CAGR of USD 310.77 million. The market is experiencing significant growth due to several key trends. The increase in the production of light vehicles has boosted the demand for oil mist collectors in the automotive industry. In addition, the government's efforts to promote the growth of the machine tool industry in various aspects have also driven the growth of the market. Another trend that has influenced the market is the growth of the market for efficient machines, as these machines usually require an effective oil mist collection system to ensure operation. These trends, coupled with the growing awareness of the growing occupational health and safety regulations, are expected to drive the market in the coming years.

Asia Pacific is expected to contribute 57% to the growth of the global market. The data provides a detailed analysis of regional trend drivers and associated factors that will continue to forecast the market. The market is experiencing significant growth, especially in the Asia Pacific (APAC) region, where these countries have a large manufacturing industry, which has significantly stimulated the demand for machine tools, thereby driving the market.

Oil centrifugal force is used to separate the oil mist particles from the atmospheric filtration. Using a filtration system, the collected oil mist particles can be reused or recycled, making it an environmentally friendly solution. Without a filtration system, the oil mist particles can cause air pollution and pose health risks. The aerospace industry is another end-user of oil mist collectors due to the stringent increase in process manufacturing precision requirements.

The demand for oil mist collectors in Asia Pacific is expected to outpace developed regions such as North America and Europe due to the establishment of new production plants and expected expansion of existing ones.

Analyzed the data with 2023 as the base year and analyzed the key drivers, trends, and challenges. A thorough analysis of the drivers will help companies improve their marketing strategies to gain an edge.

Oil Mist Collector Market Drivers

Increasing production of light vehicles is the main driver of the market. The market is experiencing significant growth due to the increasing demand for improved air quality in industrial processes, especially machining and metalworking. These processes generate tobacco-containing oil droplets and airborne particles, which pose a threat to workers' health and negatively affect machinery efficiency. To mitigate these issues, various industries are adopting oil mist collectors and separators, which utilize centrifugal separators, filtration systems, and high-efficiency electrostatic precipitators. Increasingly stringent emission standards require the use of environmentally friendly materials and energy-saving technologies such as IoT integration

In addition, the use of oil mist collectors can improve the sustainability of manufacturing processes by minimizing energy consumption and promoting environmental sustainability. The application areas of oil mist collectors include various optimization aspects of industries such as machining, metalworking, textiles, and air quality engineering to ensure performance and comply with air quality regulations.

Oil Mist Collector Market Trends

Government-driven development of the machine tool industry is a future trend in the market. The market is experiencing significant growth due to the need to pay attention to improving air quality in industrial processes. Machining and metalworking operations generate fumes containing oil droplets and airborne particles, which pose a threat to workers' health and reduce machine efficiency. To address these issues, emission standards for oil mist collectors centrifugal separators require the use of these systems to control air and ensure air quality pollution.

In the textile industry, oil mist collectors are essential during processing to minimize the emission of chemical vapors and oil mist. Air Quality Engineering companies specialize in designing and implementing wet oil mist collection systems while meeting stringent air quality requirements to ensure that human health is not polluted.

Oil Mist Collector Market Challenges

The growth of the used machine tool market is a key challenge that affects the growth of the market. The market faces huge challenges due to the expansion of the used machine tool market. Due to the high labor costs and strict emission standards, the manufacturing industry in developed regions such as the United States and Europe has closed down, increasing the supply of used machinery. However, Asian countries such as India and Pakistan are importing these machines, which often produce tobacco and airborne particulate matter, including oil droplets, which leads to unhealthy fertilizers and reduces machine efficiency. To address these issues, oil mist collectors such as centrifugal separators and filtration systems are essential to maintain clean air quality during efficient industrial processes.

These systems help eliminate oil mist, ensure compliance with emission standards, and promote energy efficiency and environmental sustainability. By prioritizing worker safety, air quality requirements, and chemical air pollution control, industry can ensure its efficient machinery operates in an environmentally friendly manner during wet processing and metalworking.