0102030405

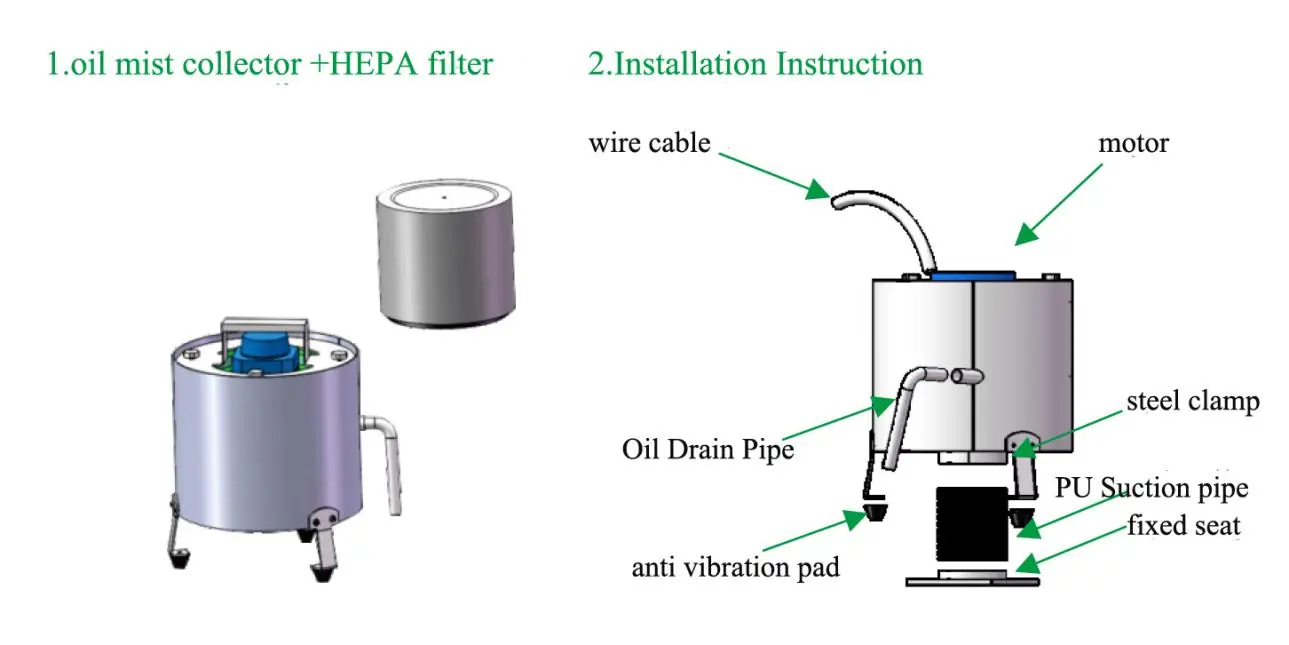

Oil Mist Collector / Air Cleaner

Parameter

| Model | LJ-250A1 | LJ-370A1 | LJ-750A1 | LJ-750L1 | LJ-1100L1 |

| Power | 0.25kW | 0.37kW | 0.75kW | 0.75kW | 1.1kW |

| Voltage | 380V/220V/3P | 380V/220V/3P | 380V/220V/3P | 380V/220V/3P | 380V/220V/3P |

| Frequency | 50Hz | 50Hz | 50Hz | 50Hz | 50Hz |

| Air volume | 700 m³/h | 1100 m³/h | 1400 m³/h | 2300 m³/h | 3000 m³/h |

| RPM |

2800 |

2800 |

2800 |

2800 |

2800 |

| Inlet diameter |

125mm |

150mm |

150mm |

150mm |

150mm |

| Weight | 21kg | 30kg | 35kg | 38kg | 42kg |

| Dimension | 380*850 | 430*950 | 470*950 | 470*950 | 470*1100 |

Features

1. Small size, low energy consumption, large air volume. The centrifugal structure design makes the product small in appearance and saves installation space. The low resistance of the oil mist machine makes the air volume achieved under the same power larger, energy-saving and efficient;

2. High filtration efficiency. The product is equipped with filter cotton and high efficiency filter at the back end of the centrifugal structure to ensure filtration accuracy and efficiency. Since the centrifugal structure is designed for pretreatment, higher purification efficiency can be achieved with filter cotton in the later stage. Compared with the traditional filter cotton oil mist collector, less filter cotton is required and the cost is lower.

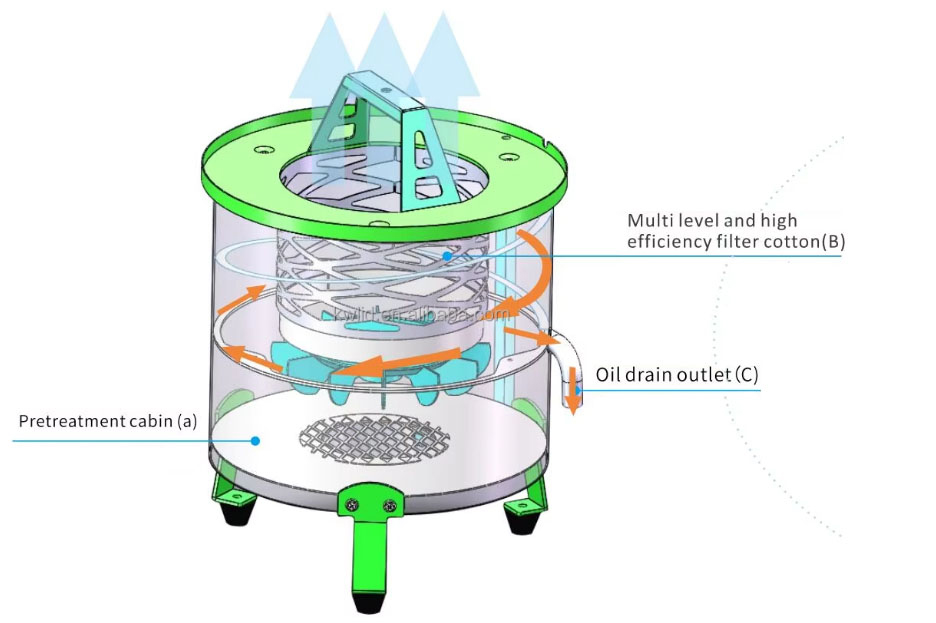

Working principle

(A)The polluted air around the machine tool will be sucked into the pre-treatment chamber at the bottom of the product. By the centrifugal force produced by the rotating turbine and the accelerating effect of coalescence principle, the oil mist can be easily combined and transformed into liquid state.

(B)The multi-level and high-efficiency filter cotton can intercept03and capture even the smallest particulate pollutants, and prevent the release and diffusion of pollutants in the factory workshop again.

(C)The special oil drain pipe is designed to return the oil to the04machine tool for reuse.

●The structure

Benefits of oil mist recovery

Improve workshop environment and enhance company image

Reduce the occupational diseases of employees and reduce the turnover rate

Saving the loss of cutting oil

Reduce the cost of workshop cleaning

Protect the environment and benefit the society

How to maintenance

1. External cleaning

Clean the outside and outlet of the oil mist collector every 1000 hours of operation or when

working conditions require frequent operation of the machine.

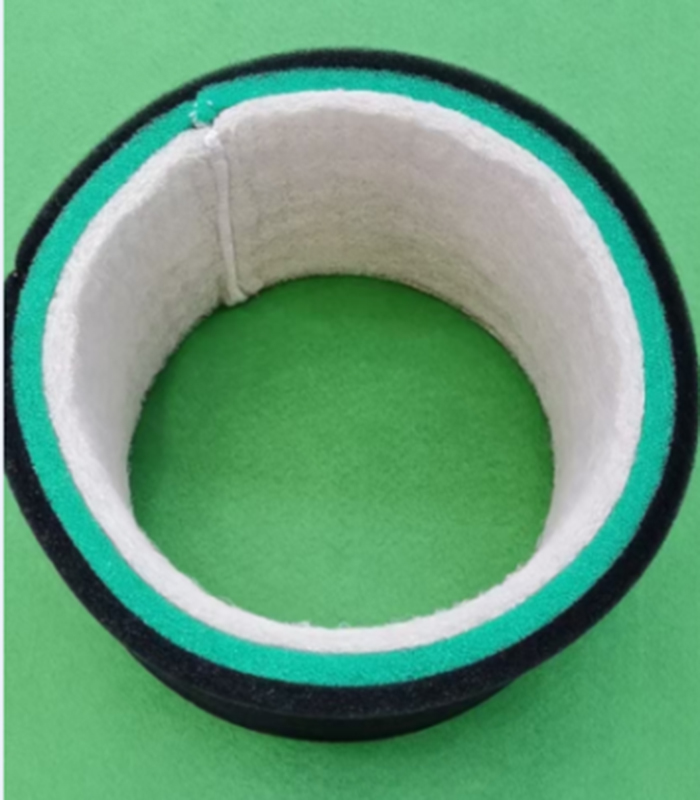

2. Cleaning of Filter cotton

Note: Used filter cotton belongs to special waste, storage and disposal should be carried out according to the current regulations.

It is advisable to change the filter cotton regularly (6 months -1 year). If the filter cotton is still structurally sound, the filter cotton can be regenerated (rather than replaced). Place the filter cotton in a solution of industrial cleaner and water for about 12 hours. Dry it with compressed air or air before replanting it in the oil mist collector.

3. Internal Cleaning

Carefully and regularly check the inside of the oil mist collector and the flat blades of the centrifugal turbine to avoid residual metal powder, sludge, or other substances that may cause imbalance in the centrifugal motor, so that the oil mist collector can maintain efficient operation and extend its life.

For internal cleaning of oil mist collector blades, use a cleaning brush and dip it into a solution of industrial detergent mixed with water, or use standard cleaning soap.

4. Replacing the filter cotton