0102030405

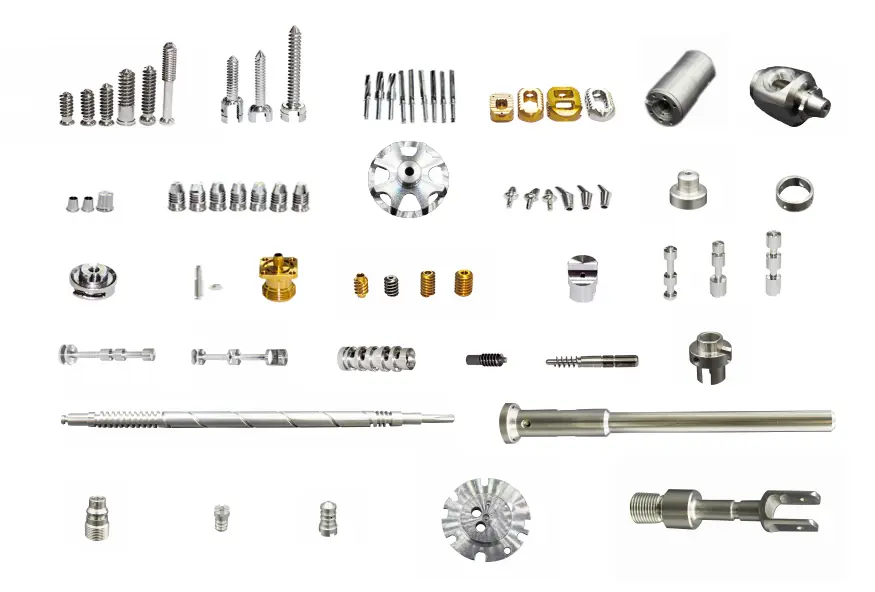

Precision CNC Machining Brass Parts

Brass

Despite its relatively high price, brass is a popular metal for CNC milling due to its excellent machinability, corrosion resistance, and aesthetic appeal. It also offers a smooth surface finish that can be easily polished for a superior look. Brasses can be grouped into three main categories, non-leaded 200 Series, leaded 300 Series, and Tin brass 400 Series.

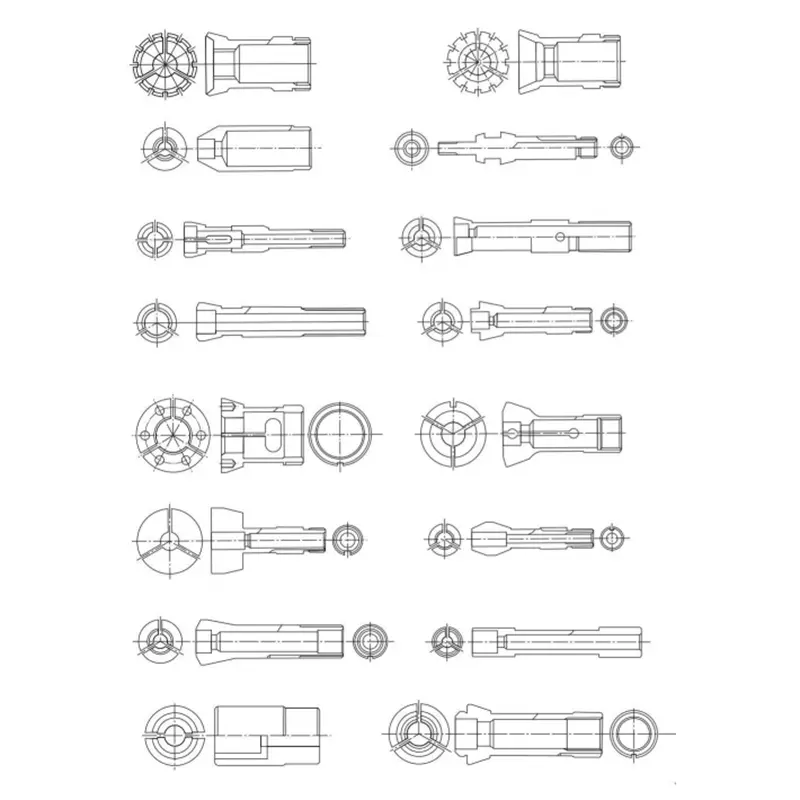

CNC Mill-Turn Machining

Definition: CNC Mill-Turn Machining is an advanced manufacturing process that combines milling and turning operations in a single machine, controlled by computer numerical control (CNC) technology.

Key Features: CNC Mill-Turn Machines feature multiple spindles, live tooling, and automated tool changers, allowing for simultaneous milling, turning, drilling, and tapping operations.

Versatility: CNC Mill-Turn Machining enables the production of complex, multi-dimensional components in a single setup, reducing production time and enhancing overall efficiency.

Products Description

In the realm of manufacturing, precision is the cornerstone of success. As industries evolve, so do the demands for custom parts and components with intricate designs and flawless functionality. At our factory, we specialize in CNC turning machining, harnessing the power of advanced technology to deliver unparalleled precision and customized solutions.

Precision Engineering

Our team of skilled engineers leverages state-of-the-art CNC turning machinery to achieve remarkable precision in the manufacturing process. From simple to complex geometries, we meticulously program and execute every movement, ensuring strict adherence to your design specifications. With CNC turning machining, we guarantee the highest level of accuracy and consistency in every component produced.

Efficient and Cost-effective

CNC turning machining is renowned for its efficiency and cost-effectiveness. Our advanced equipment minimizes production time and maximizes output, resulting in shorter lead times and increased productivity. Additionally, precise machining reduces material waste, offering cost savings for your projects without compromising quality.

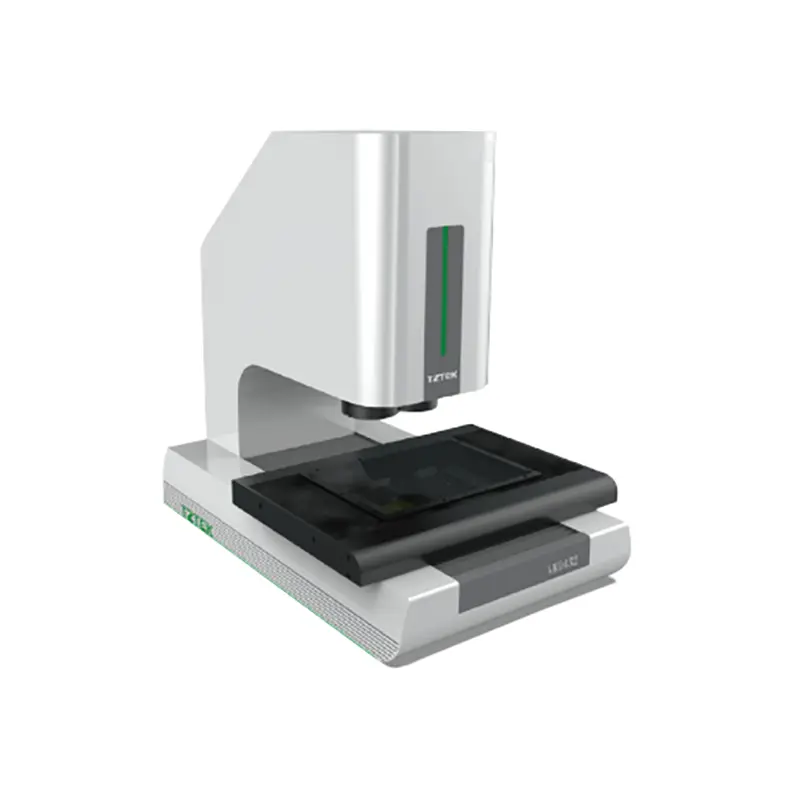

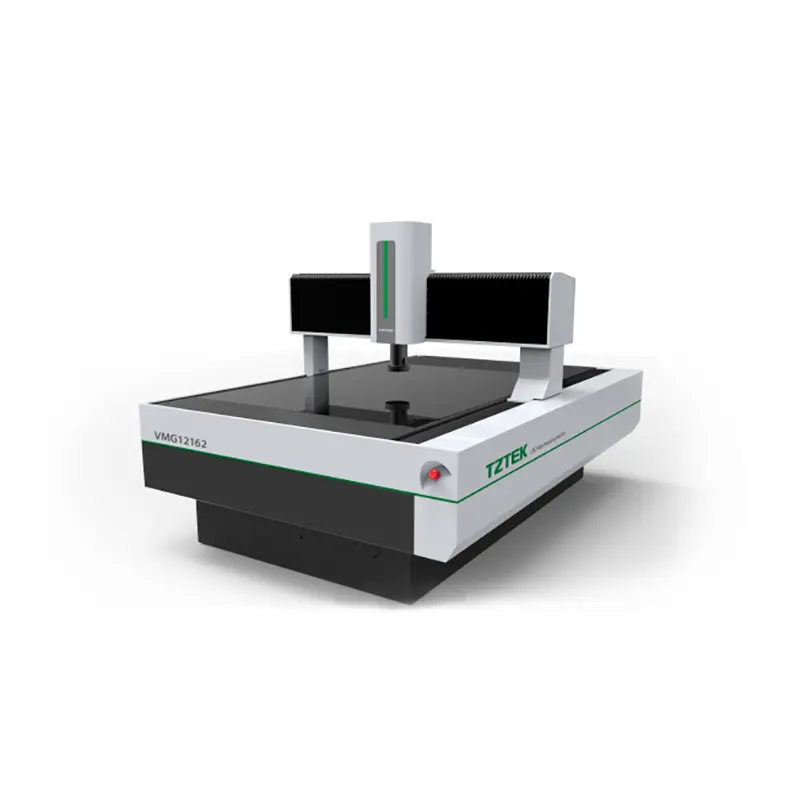

Rigorous Quality Control

Quality is the foundation of our CNC turning machining process. We implement rigorous quality control measures throughout the production cycle, conducting thorough inspections and tests to verify the precision and accuracy of each component. Our commitment to quality ensures that you receive products of exceptional reliability and performance.