Portable Oil Water Chip Separator Integrated Fo...

During the use of the machine tool, all kinds of metal debris, powder, and silt will gradually accumulate in the water tank of the machine tool. lf it is not cleaned for a long time, the volume of the water tank will become smaller, and the cutting fluid will not be fully utilized and circulated. Cause pipeline blockage, water pump and parts scrapped. There will be a lot of metal debris and sludge inside, which is smelly and dirty, and it is very troublesome to deal with. The slag extractor can solve the problems of machine tool water tank debris and sludge with one click. And with complete functions, one slag extraction and liquid exchange oil water separation integrated machine can handle the sanitation of a workshop, hand-held mode, 360°no dead angle cleaning. The machine has a maximum storage capacity of 200L, has the functions of slag pumping, liquid replacement, oil-water separation, etc., and can be used for both dry and wet purposes. lt can clean the debris and oil sludge in the water tank of the machine on-line, realize the discharge while pumping, without stopping the machine, separate the sludge, water and oil, and recycle and store them.

Oil Mist Air Cleaners/Oil Mist Purifier

Do you know the dangers of oil mist?

● Oil mist

● Ammonia

● Water mist

● Oil contamination

● Dust

● Soot

● Peculiar smell

Oil mist can cause headaches, rough skin, chronic bronchitis, chest discomfort, respiratory irritation, allergic skin diseases

Industrial Electrostatic CNC Oil Mist Collector...

BOD Oil Mist Collector Smoke Dust Air Cleaner is suitable for CNC numerical control lathe, washing machine, Surface grinding machine, gear hobbing and milling machine and the slotting machine, vacuum pump, spray laboratory, electrical discharge machining, CNC machining center.

Oil Mist Collector / Air Cleaner

Small size, low energy consumption, large air volume. The centrifugal structure design makes the product small in appearance and saves installation space. The low resistance of the oil mist machine makes the air volume achieved under the same power larger, energy-saving and efficient.

Feeding Machine Collect Series

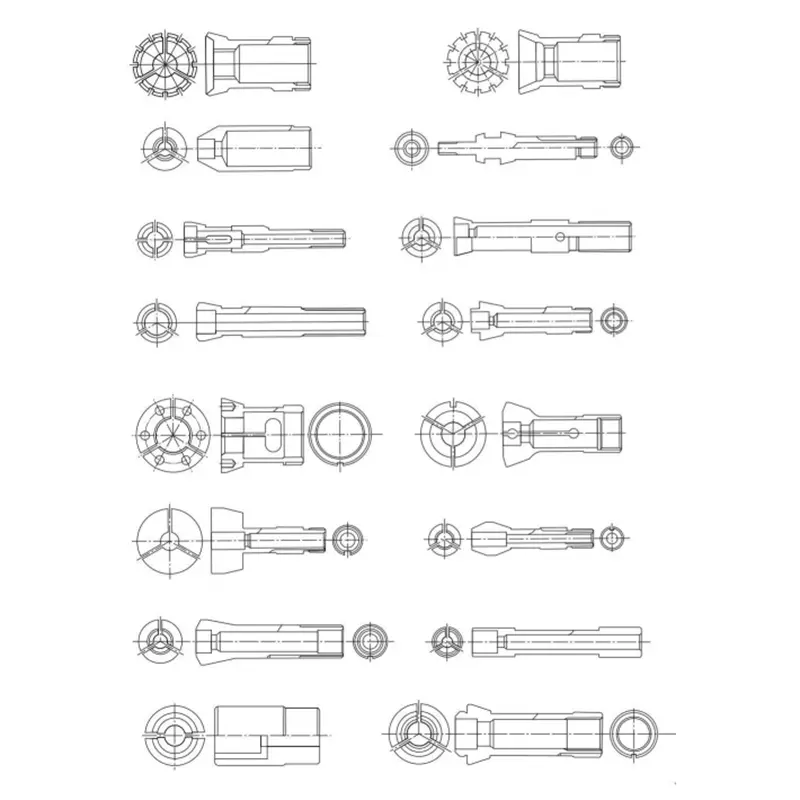

The production engineering possibilities of BOD allow us manufacture finest quality products. Our collets & Guide Bushes are easily interchangeable. Our products are used across the globe for High Precision requirements.

Our collets & Guide Bushes are available in variety of standard sizes and shapes. It is manufactured from High quality special grade steel for high hardness , wear resistance and best functioning.

CNC Lathe Collet Series

Spring collets are perishable tools for fixing a workpiece at the processing, or fixing cutting tools, and used as some parts of a machine or a conveyance machine. It consists of a collet and devices, and a workpiece is that the collet included in the workholding devices open and close, and performs clamping and unclamping of a workpiece.

Spring collets are various by object works, such as size, the clamping method, and clamping force. There is a various shaped spring collets’ form as you can see the top page of a spring collets, and they are used for fix of a workpiece or cutting tools. In case of scroll chuck, a workpiece is clamped by three or four jaws. On the other hand, when we use spring collets, a workpiece is clamped as wrapping in with the number of flexing slot of the collet. Therefore, since the pressure concerning one point ends few, it can clamp powerfully, without pressure's distributing and damaging the whole clamping portion of the workpice.

Multi-spindletapping Machine Collets

The production engineering possibilities of BOD allow us manufacture finest quality products. Our collets & Guide Bushes are easily interchangeable. Our products are used across the globe for High Precision requirements.

Our collets & Guide Bushes are available in variety of standard sizes and shapes. It is manufactured from High quality special grade steel for high hardness , wear resistance and best functioning.

Precision ER Flexible Collets for CNC machine

The ER collet is a type of clamping system designed to hold tools or workpieces with utmost precision. Characterized by their unique external profile and slits, these collets provide a wide clamping range, making them versatile for various applications. The “ER” stands for “Elastic Regular”, indicative of their elastic deformation capability, which ensures a tight grip. They are installed on CNC lathes.

The science behind their design is truly fascinating. ER collets are crafted to have a slight taper, allowing them to compress onto the tool or workpiece as the collet nut is tightened. This ensures a centered and secure hold, minimizing any potential runout. The precision of ER collet is not just by chance; it’s a result of meticulous engineering. Their design ensures that the force is evenly distributed, providing a consistent grip and preventing tool slippage, making them a favorite in high-precision machining tasks.

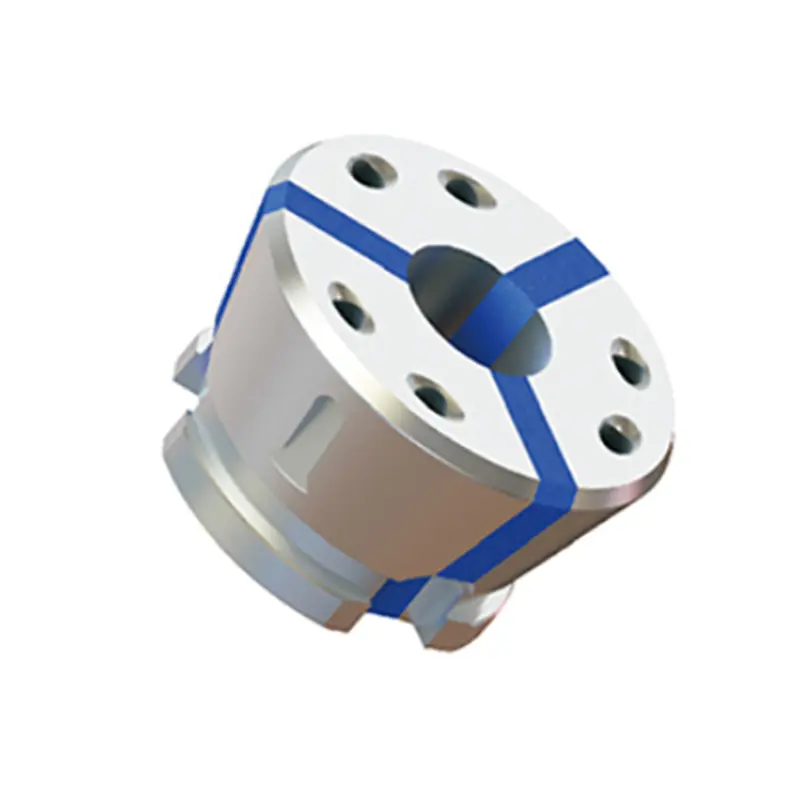

Special Collets Shape Case custom service

The production engineering possibilities of BOD allow us manufacture finest quality products. Our collets & Guide Bushes are easily interchangeable. Our products are used across the globe for High Precision requirements.

Our collets & Guide Bushes are available in variety of standard sizes and shapes. It is manufactured from High quality special grade steel for high hardness , wear resistance and best functioning.

Front Push Series Rubber-Flex Collets

● Accuracy <0.01mm

● Parallel grip

● Short change over time

● Wear-resistant material

● Available in smooth, radial groove or serrated

T210 & T211 & T212 Series Rubber-Flex Collets

● Accuracy <0.01mm

● Parallel grip

● Short change over time

● Wear-resistant material

● Available in smooth, radial groove or serrated

SK Series Rubber-Flex Collets for workholding

● Accuracy <0.01mm

● Parallel grip

● Short change over time

● Wear-resistant material

● Available in smooth, radial groove or serrated