90 Degree Angle Head DK90-BT30-3M

Features:

1. Optional drive tool holder

2. Imput tool holder and shaft is in one-piece design

3. Warranty: 1 years

Details:

1. The housing is made of aircraft-grade aluminum. After precision machining and aging treatment, it has the features of long service life, outstanding rigidity and accuracy. Allows a minimum pass of Φ25mm

2. The main drive shaft is made of special alloy material. It can achieve high stability during the transmission after processed by strict heat treatment and grinding finish.

3. The imported gears and bearings with good quality ensure the high torque and low noise in transmission.

4. The way of input and output are fexible and diverse.Not limited to connecting with BT shanks and ER collets,our angle heads can meet all kinds of precision machining equipment for milling, drilling,tapping and grinding processes etc.

3/8“ Water Separator

The split type design is convenient to disassemble the auto-drain part from the water separator.

Maintenance free with auto-drain

Maximum Operating Pressure: 16 bar

Particle removal: 1 micron

Material (housing): Aluminium Alloy

Drain Connection: 1/2"

3/8“ Water Separator the Built-In Auto-Drain

The built-in auto-drain has a clean look and designed to remove all contaminants from the water separator automatically.

Maintenance free with built-in auto-drain

Maximum Operating Pressure: 10 bar

Particle removal: 1 micron

Material (housing): Aluminium Alloy

Compressed Air Filter water separator

Differential pressure gauge and auto-drain are available

It works better when use with BOD water separtator together.

Maximum Operating Pressure: 16 bar

Particle removal: 0.01 micron

Material (housing): Aluminium Alloy

Drain Connection: 1/2"

High qualtity OEM Custom Machining Cnc Turning ...

BOD Management

To achieve data analysis and decision support, integrated management ofvarious departments, information sharing and collaborative work. Help us to achieve the optimal allocation of resources, to avoid waste and repeat-ed use of resources, we can grasp the business situation in real timemake timely decisions, improve management efficiency and reduce costsso as to improve competitiveness.

Industrial Machine Lathe Water tank Deslagging ...

• Remove floating debris from liquid surface

• Remove iron filings

• Remove aluminum powder

• Remove sediment

• Purifies and extends fluid life

• The filtration precision is 1mm, and the maximum filtration precision is 0.1mm (optional).

• Widely used in metal cutting, aluminum processing, grinding, engineering plastics... etc. can be processed.

• Based on physical principles, processing liquid in the CNC water tank can be purified, and the sludge can also be removed in a short time.

• Solve the problem of long-term deposition of iron filings, aluminum powder, fine mud, etc. in the machine tool water tank after cutting.

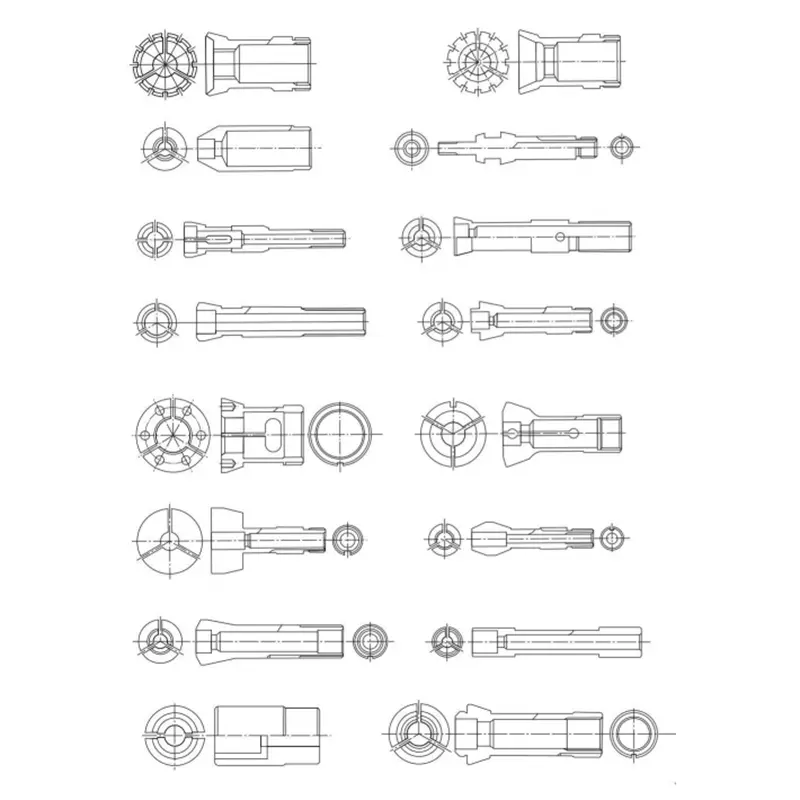

Custom Precision CNC Machining Milling Turning ...

From rapid prototyping to mass production, BERGEK provides a one-stop CNC machining service, integratingCasting,3D printing, laser cutting, welding, plastic iniection molding and more. Save up to 30% in costs with oulefficient processes.

Precision CNC Machining Brass Parts

We can process ≤Φ42MM bars of stainless steel, brass and aluminium. These precision metal works are widely used in aerospace, military, automotive, medical equipment hydraulic and other industries.

Swiss machining, also known as Swiss turning, is a high-precision CNC machining process performed on a special type of turning machine designed specifically to produce small and intricate parts.

Swiss lathes operate with incredibly small tolerances at shorter cycle times than conventional lathes, making them an attractive option for manufacturing complex parts at larger volumes.

Precision CNC Machining Stainless Steel Parts

We can process ≤Φ42MM bars of stainless steel, brass and aluminium. These precision metal works are widely used in aerospace, military, automotive, medical equipment hydraulic and other industries.

Swiss machining, also known as Swiss turning, is a high-precision CNC machining process performed on a special type of turning machine designed specifically to produce small and intricate parts.

Swiss lathes operate with incredibly small tolerances at shorter cycle times than conventional lathes, making them an attractive option for manufacturing complex parts at larger volumes.

Precision CNC Machining Aluminium Parts

We can process ≤Φ42MM bars of stainless steel, brass and aluminium. These precision metal works are widely used in aerospace, military, automotive, medical equipment hydraulic and other industries.

Swiss machining, also known as Swiss turning, is a high-precision CNC machining process performed on a special type of turning machine designed specifically to produce small and intricate parts.

Swiss lathes operate with incredibly small tolerances at shorter cycle times than conventional lathes, making them an attractive option for manufacturing complex parts at larger volumes.

Machine Oil-water Separator Slag Extraction And...

1. The whole machine is made of stainless steel, with full copper dual motors and a built-in stainless steel water pump;

2. Double-motor vacuum drive, strong suction, never clogged;

3. Two-stage filtration,filtration accuracy up to 10um, no consumables;

4. One-button start, double system protection, safe, efficient and fast;

5. Liquid level control design in the water tank, automatic start-stop

function,oil-water separation and discharge;

6. 200L liquid storage tank and 40Limpurity volume,large processing capacity without frequent cleaning;

7. Equipped with swivel casters, easy to move, easy to drain and dump slag.cleaning water tanks of machine tools