Portable Oil Water Chip Separator Integrated Fo...

During the use of the machine tool, all kinds of metal debris, powder, and silt will gradually accumulate in the water tank of the machine tool. lf it is not cleaned for a long time, the volume of the water tank will become smaller, and the cutting fluid will not be fully utilized and circulated. Cause pipeline blockage, water pump and parts scrapped. There will be a lot of metal debris and sludge inside, which is smelly and dirty, and it is very troublesome to deal with. The slag extractor can solve the problems of machine tool water tank debris and sludge with one click. And with complete functions, one slag extraction and liquid exchange oil water separation integrated machine can handle the sanitation of a workshop, hand-held mode, 360°no dead angle cleaning. The machine has a maximum storage capacity of 200L, has the functions of slag pumping, liquid replacement, oil-water separation, etc., and can be used for both dry and wet purposes. lt can clean the debris and oil sludge in the water tank of the machine on-line, realize the discharge while pumping, without stopping the machine, separate the sludge, water and oil, and recycle and store them.

Industrial Machine Lathe Water tank Deslagging ...

• Remove floating debris from liquid surface

• Remove iron filings

• Remove aluminum powder

• Remove sediment

• Purifies and extends fluid life

• The filtration precision is 1mm, and the maximum filtration precision is 0.1mm (optional).

• Widely used in metal cutting, aluminum processing, grinding, engineering plastics... etc. can be processed.

• Based on physical principles, processing liquid in the CNC water tank can be purified, and the sludge can also be removed in a short time.

• Solve the problem of long-term deposition of iron filings, aluminum powder, fine mud, etc. in the machine tool water tank after cutting.

Machine Oil-water Separator Slag Extraction And...

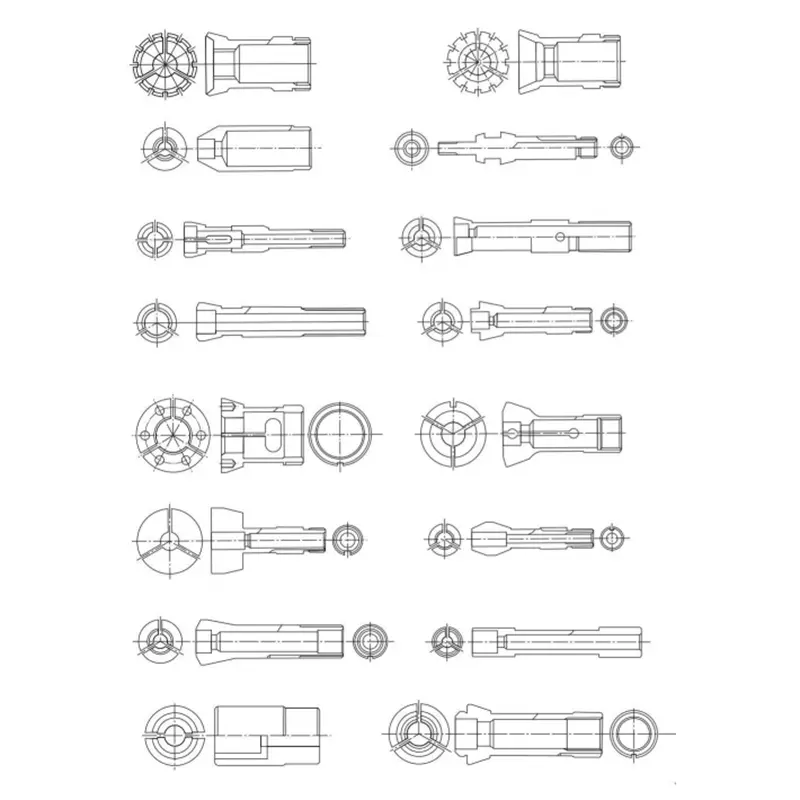

1. The whole machine is made of stainless steel, with full copper dual motors and a built-in stainless steel water pump;

2. Double-motor vacuum drive, strong suction, never clogged;

3. Two-stage filtration,filtration accuracy up to 10um, no consumables;

4. One-button start, double system protection, safe, efficient and fast;

5. Liquid level control design in the water tank, automatic start-stop

function,oil-water separation and discharge;

6. 200L liquid storage tank and 40Limpurity volume,large processing capacity without frequent cleaning;

7. Equipped with swivel casters, easy to move, easy to drain and dump slag.cleaning water tanks of machine tools