0102030405

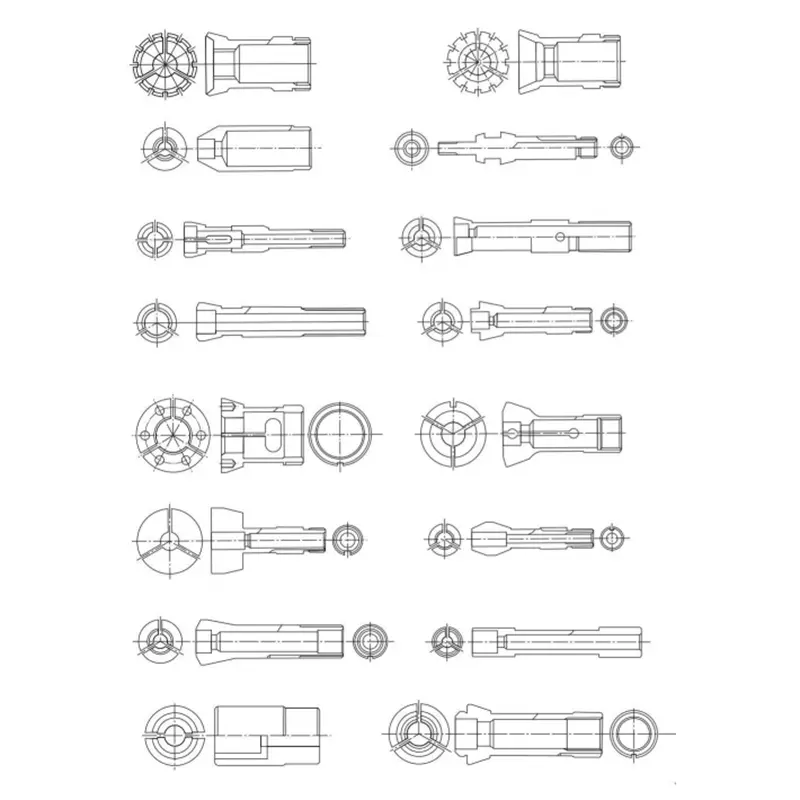

CNC Lathe Collet Series

CNC Lathe Collet Series 1 Parameters

| Machine Type | Machine Model | ΦDmm | Lmm | Clamping size | Material |

| NOMURA P8# | NSP8410 NSP8420 | Φ12.0 | 58 | Φ8.0 | Steel/Carbide |

| NOMURA P10# | NSP1053 TSUGAMIB012 | Φ16.0 | 50.5 | Φ10.0 | Steel/Carbide |

| NOMURA P16# | NSP1053 TSUGAMIB012 | Φ20.0 | 67 | Φ16.0 | Steel/Carbide |

| NOMURA P20# | NH-20KF | Φ26.0 | 67 | Φ20.0 | Steel/Carbide |

| NOMURA P25# | NH-25K NHC-P2553 | Φ32.0 | 84.5 | Φ25.0 | Steel/Carbide |

| TSUGAMI 7# | T7 B007 BM07 | Φ10.0 | 46 | Φ7.0 | Steel/Carbide |

| TSUGAMI L-10# | L-10 NP-11 NT-11 | Φ14.0 | 47 | Φ10.0 | Steel/Carbide |

| TSUGAMI NP17# | NP17 NT17 NP16 NT16 | Φ23.8 | 62 | Φ17.0 | Steel/Carbide |

| TSUGAMI BS-20# | BO18 S20 BS18 | Φ28.0 | 77 | Φ20.0 | Steel/Carbide |

| BO18 A-axis | |||||

| TSUGAMI BS-20# BO18 B-axis | BO18 S20 BS18 | Φ25.0 | 77 | Φ20.0 | Steel/Carbide |

| TSUGAMI BS-26# A-axis | BS26 S-25 | Φ33.0 | 80 | Φ25.0 | Steel/Carbide |

| TSUGAMI BS-26# B-axis | BS26 S-25 | Φ30.0 | 80 | Φ25.0 | Steel/Carbide |

| CITIZEN B-12# | B-12 TSUGAMIBO12 HANWHA12# | Φ16.0 | 62 | Φ12.0 | Steel/Carbide |

| CITIZEN SB16# | L16 L20 F16 F20 | Φ20.0 | 67 | Φ16.0 | Steel/Carbide |

| CITIZEN BL-20# | BL20 | Φ33.0 | 100 | Φ25.0 | Steel/Carbide |

| CITIZEN L-20# | L20 M16 G20 E20 | Φ26.0 | 67 | Φ20.0 | Steel/Carbide |

| CITIZEN F-25# | L25 F25 E25 | Φ30.0 | 78 | Φ25.0 | Steel/Carbide |

| CITIZEN VNC-32# | VNC-32# | Φ37.0 | 92 | Φ30.0 | Steel/Carbide |

| STAR SJ-8R | SJ-8R | Φ12.0 | 51 | Φ8.0 | Steel/Carbide |

| STAR SNC10# | JNC10 SNC10 RNC10 | Φ15.0 | 64 | Φ10.0 | Steel/Carbide |

| STAR SE-12# | S13 VNC12 SJ15 | Φ18.0 | 67 | Φ14.0 | Steel/Carbide |

CNC Lathe Collet Series 2 Parameters

| Clamping size | Material |

| Φ16.0 | Steel/Carbide |

| Φ20.0 | Steel/Carbide |

| Φ32.0 | Steel/Carbide |

| Φ7.0 | Steel/Carbide |

| Φ10.0 | Steel/Carbide |

| Φ16.0 | Steel/Carbide |

| Φ20.0 | Steel/Carbide |

| Φ30.0 | Steel/Carbide |

| Φ16.0 | Steel/Carbide |

About an order to BOD

At first time order

About spring collets and workholding devices, we will check customer’s specification, and after exchanging the confirmation of drawings and specifications, then we will start manufacturing. Please ask our sales branch about arranging specification, price, and time of delivery.

At repeat order

We can manufacture without exchanging the confirmation of specifications if we have production history or manufacturing drawings. Please ask our sales branch about arranging price, and time of delivery.

Why Choose Us

● Made from quality steels, carbides

● Faster Delivery

● Strong Customer Support

● High Quality and Precision

● Quality driven process and control

● All processes and facilities under one roof

● Dedicated/Skilled Manpower

● Customised Solutions

Quality Policy

We will supply quality products that comply with specified requirements and earn our customers’ satisfaction through continuous improvement efforts, an effective quality management system, and the dedicated efforts of all employees.

Quality Control

* We have specialized QC testers to check the quality of the products according to different customers' requirement.

* We have IQC to check the dimensions and surface of the incoming material.

* We have PQC to inspect full-course during the manufacturing processing.

* We have FQC to inspect all the anodizing/plating and other finishes' products from our supplier and proceed with the professional quality and appearance inspection before shipping.